Functions

2.8 Motor Protection

SIPROTEC, 7SJ62/64, Manual

C53000-G1140-C207-2, Release date 01.2008

160

The tripping time is calculated based on the following equation:

with

t

TRIP

Actual tripping time for flowing current

I

t

max STARTUP

Tripping time for nominal startup current

I

STARTUP

(address

4103

,

STARTUP TIME

or

4105

,

STARTUP T WARM

)

I

Current actually flowing (measurement value)

I

STARTUP

Nominal startup current of the motor (address

4102

,

STARTUP CURRENT

)

I

MOTOR START

Pickup value for recognition of motor startup (address

1107

,

I MOTOR START

),

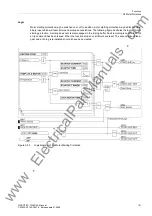

Figure 2-52

Inverse time tripping curve for motor starting current

Therefore, if the startup current

I

is smaller (larger) than the nominal current

I

STARTUP

(parameter

STARTUP

CURRENT

) as configured under address

4102

, then the actual tripping time t

Trip

is prolonged (or shortened) ac-

cordingly (see Figure 2-52).

Definite Time Overcurrent Tripping Characteristic (Locked Rotor Time)

Tripping must be executed when the actual motor starting time exceeds the maximum allowable locked rotor

time if the rotor is locked. The device can be informed about the locked rotor condition via the binary input

(

„>Rotor locked“

), e.g. from an external r.p.m. monitor. The motor startup condition is assumed when the

current in any phase exceeds the current threshold

I MOTOR START

. At this instant, the timer LOCK ROTOR

TIME is started.

The locked rotor delay time (

LOCK ROTOR TIME

) is linked to a binary input

„>Rotor locked“

via an AND

gate. If the binary input is picked up after the set locked rotor time has expired, immediate tripping will take

place regardless of whether the locked rotor condition occurred before, during or after the timeout.

www

. ElectricalPartManuals

. com