Siemens Building Technologies

O3341(RWD32) V14.doc

O3341A031En2

8-Jun-01

Page 11

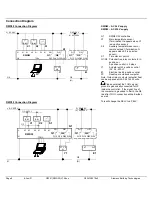

Mounting Possibilities

A

B

C

D

3341z02

There are four possibilities for mounting the RWD82/RWD32 controller

Mounting Installation

The RWD32/82 controllers can be mounted as follows:

Observe all local installation and mounting regulations.

A

On DIN rail (EN 50 022-35 x 7.5) at least 120 mm long for RWD82 and 170 mm long for RWD32

B

For wall mounting with 2 screws

(Minimum length of the screw should be 40mm long(

φ

3.2mm.)

C

Front mounted using standard elements

e.g. 1x DIN rail 150 mm long

for RWD82 and 195 mm long for RWD32,

2 x hexagonal placeholders 50 mm, washers and screws

(Ensure all terminations are tightened before final mounting to front panel)

D

Inside the ARG62.21(RWD82 only) / ARG62.22

Note:

There must be a minimum of 8mm distance from terminations to panel/enclosures in order to avoid electric shock.

Electrical installation

Standard cables can be used for the controller. However, when mounting in an environment greatly exposed to EMI, use only shielded

cables.

•

The RWD32 is designed for AC 230 V operating voltage.

•

The RWD82 is designed for AC 24 V operating voltage.

The low voltage must comply with the requirements for safety extra-low voltage (SELV) as per EN 60730.

Use safety insulating transformers with double insulation as per EN 60742; they must be designed for 100 % on-time.

When using several transformers in one system, the connection terminals G0 must be galvanically connected.

Supplying voltages above AC 24 V to low voltage connections may damage or destroy the controller or any other connected devices.

Additionally, connections to voltages exceeding AC 42 V endanger personal safety.