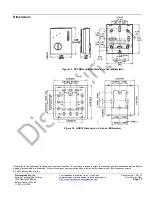

RCC10U

Technical Instructions

Document No. 155-712

September 27, 2007

Room Temperature Controller

for Two-pipe Fan Coil Units

Siemens Industry, Inc.

Description

Room temperature controller for two-pipe fan coil units.

Features

•

Output for on/off valve actuator.

•

Output for three-speed fan.

•

Dual setpoint temperature scale.

•

Control depending on the room or return air temperature.

•

Automatic Heating/Cooling changeover.

•

Operating modes: Normal, Energy Saving, Freeze Protection and Off.

•

Operating mode changeover input for remote control.

•

Selectable control parameters.

•

Operating voltage 120 Vac.

Application

Typical use:

•

Controlling room temperature in individual rooms that are heated or cooled with two-

pipe fan coil units.

•

Opening or closing a valve

•

Switching a three-speed fan.

Suitable for use in systems with:

•

Automatic Heating/Cooling changeover.

•

Heating only/Cooling only or Heating and Cooling applications.

Product Number

RCC10U

With input for return air temperature sensor