13

/20

Assembly instructions

Electro-mechanical systems

A-opener 2.2

13

/20

09.2019

H39.ELEKS011EN-00

6

Functional test

In order to check the functionality, the door and the door frame

must be positioned vertically.

If stiffness is determined during the functionality test, observe

the following points:

•

Check the tightening torque of the fixing screws on the handle

set and/or the profile cylinder lock.

•

Screws must not be screwed in too tightly or over tightened.

•

Screws should also not be screwed in at an angle. This is to

avoid the screw head blocking the drive rod behind it.

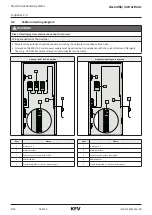

6.1

Functional test when the door is open

6.1.1

Checking the functioning of the lever handle:

f

Press the lever handle down fully.

The lever handle must return to its original position by

itself.

6.1.2

Checking the functioning of the profile cylin

-

der

f

Turn the key in the cylinder lock in the locking direc

-

tion.

It must be possible to disengage the main deadbolt

fully and easily.

f

Remove the key when the main deadbolt is dis

-

engaged (child-proof lock active, lever handle

blocked).

f

Turn the key in the cylinder lock in the unlocking

direction.

All locking elements must extend completely and

smoothly.

f

Remove the key while the locking elements are

retracted.

6.1.3

Mechanical test of the multi-point lock with

A-opener 2.2

Check the functioning of the locking elements with

the lever handle

f

Turn the key in the locking direction until the main

deadbolt extends.

The lever handle is blocked, the child-proof lock is

active.

f

Turn the key in the unlocking direction until the

main deadbolt retracts.

f

Push down the lever handle completely, the latch

must be able to retract with ease.

The latch must extend completely again after the lever

handle is released.

f

For the automatic multi-point locking system, the

locking elements of the top and bottom auxiliary

box must trigger mechanically.

f

Push down the lever handle completely, all locking

elements must retract completely.

The latch must extend completely again after the lever

handle is released.

Check the functioning of the locking elements with

the key

f

Turn the key in the locking direction until the main

deadbolt extends.

f

Turn the key in the unlocking direction.

All locking elements must retract.

f

The latch must extend completely again after the

key is released.

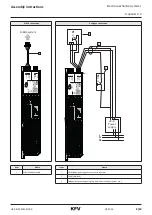

6.2

Functional test when the door is closed

f

Close the door.

f

Repeat the test step "Functional test when the door

is open".

f

All locking elements must extend and retract freely

in the frame parts.

6.3

Electromechanical test

f

Switch on the supply voltage.

f

Close the door.

f

Check the external unlocking (e.g. button or inter

-

com system).

f

Check the function of the optional access control

system.

If an optional access control system (e.g. a fingerprint

scanner) is to be installed in combination with an au

-

tomatic multi-point locking system with A-opener 2.2,

refer to the relevant instructions for information about

commissioning and testing.

Содержание KFV A-Opener 2.2

Страница 2: ......

Страница 18: ...Electro mechanical systems Assembly instructions A opener 2 2 09 2019 18 20 H39 ELEKS011EN 00...

Страница 19: ......

Страница 20: ...www siegenia com H39 ELEKS011EN 00...