Additional test

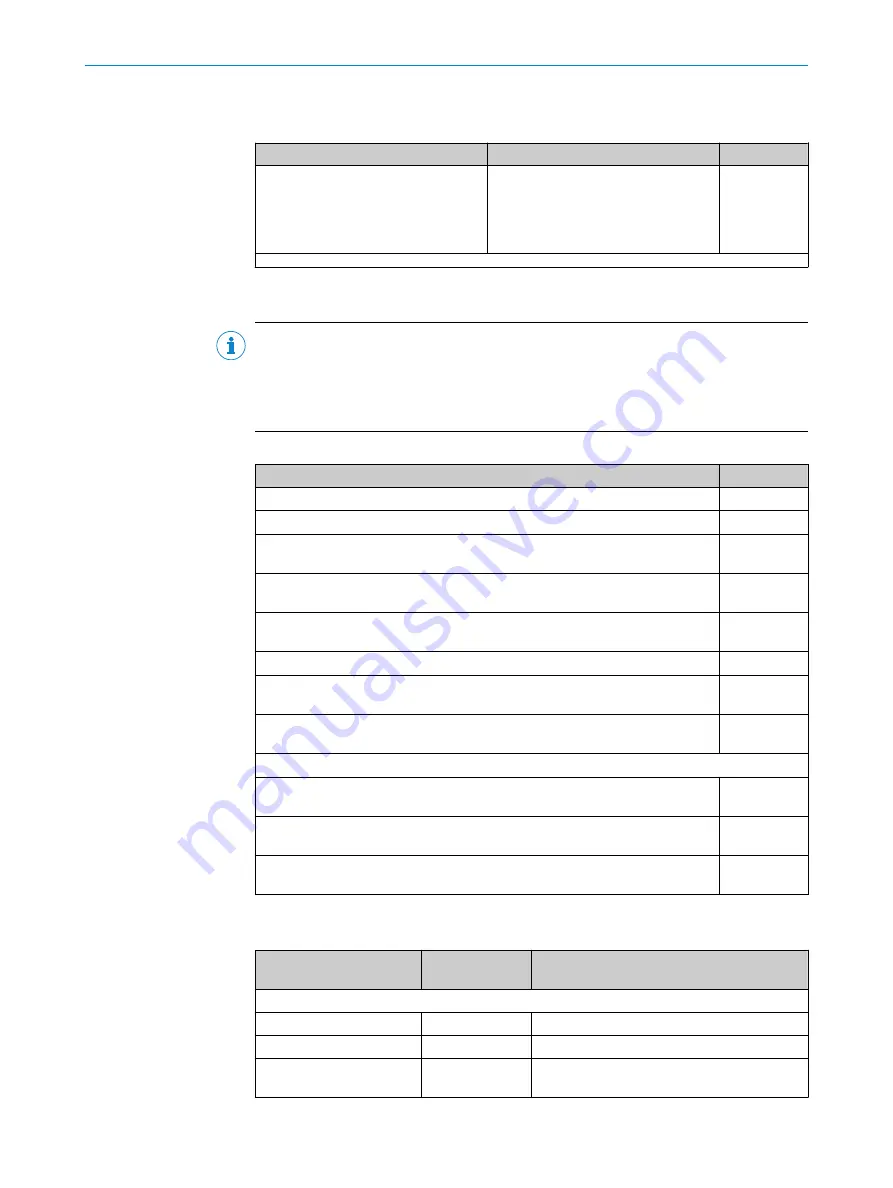

Table 48: Additional test

Test sequence

Expected result

Result OK?

1.

Start the robot in the manual

operating mode with reduced

speed.

2.

Switch to the Automatic operating

mode.

The robot stops. The robot must be

manually restarted.

Yes

⃞

No

⃞

16.2

Requirements for automatic restart

NOTE

The following checklist only applies to this specific safety system and no claim is made

for completeness.

Pursuant to the manufacturer’s risk assessment, additional requirements may be nec‐

essary.

Table 49: Checklist for the manufacturer

Requirements

It is not possible to walk behind the protective field of the laser scanner.

Yes

⃞

No

⃞

It is ensured that no people are in the hazardous area during or after the reset.

Yes

⃞

No

⃞

The hazardous area can only be entered when passing through the protective

field of the laser scanner.

Yes

⃞

No

⃞

Appropriate measures have been taken to protect people within the hazardous

area (fence, screen, etc.) or to provide monitoring activities (protective device).

Yes

⃞

No

⃞

Additional protective measures (fence, screen, etc.) are installed in such a way

as to prevent their removal or tampering.

Yes

⃞

No

⃞

Protective devices are protected against manipulation.

Yes

⃞

No

⃞

Protective devices are installed in such a way that it is not possible to stand

behind them, bypass them or crawled beneath them.

Yes

⃞

No

⃞

Guards are installed to provide the required minimum distance to the nearest

point in the hazardous area.

Yes

⃞

No

⃞

Necessary additional measures

Automated restart is not possible if the protective field becomes clear but the

warning field is not subsequently interrupted.

Yes

⃞

No

⃞

An emergency stop pushbutton is installed in the hazardous area near the

robot.

Yes

⃞

No

⃞

In the hazardous area, there is a warning sign attached with the pictogram and

note “Warning, automated start-up” (in accordance with ISO 7010-W018).

Yes

⃞

No

⃞

16.3

Overview of sensors and actuators

Reference designation

Flexi Soft

address

Description

Sensors and switches

BG210

KF112 I3/I4

microScan3 Core I/O OSSDs

BG210

KF112 I2

microScan3 Core I/O warning field

SF300

KF111 I3/I4

Emergency stop pushbutton outside the haz‐

ardous area

ANNEX

16

8024620/16AH/2019-12-02 | SICK

O P E R A T I N G I N S T R U C T I O N S | sBot Speed – YA

65

Subject to change without notice