CLV61x | SICK

8015589/ZNI9/2017-06-13 •Subject to errors and modifications • ©

SICK AG

•

Waldkirch

•

Germany

•

www.sick.com

2

4.

In order to avoid a total reflection of the scanning line, tip

the CLV61x with the following skew angle from the perpen-

dicular to the bar code surface.

Line scanner

(front reading window)

Line scanner

(lateral reading window)

(Top view)

(Top view)

105°

105°

Avoid surface reflection through correct arrangement

Connection Module CDB620

>

Mount the CDB620 connection module in the vicinity of

the CLV61x. Through the serial data interfaces (RS-232)

recommended cable length max. 5 m between both

devices. Mount the CDB620 in such a way that the device

can be accessed at all times. In relation to this, see

&

“

CDB620 Connection Module” Operating Instructions

(no.

8012119).

Step 2: Electrical Connection

•

The electrical installation must only be performed by

qualified electricians

.

•

The currently applicable safety regulations must be

observed when working in electrical systems!

• Electrical connections between the CLV61x and other de-

vices may only be created or fixed when there is no power

to the system. Otherwise, the devices may be damaged.

• When using extension cables with open ends, ensure that

bare wire ends do not come into contact with each other

(risk of short-circuit when supply voltage is switched on!).

Wires must be appropriately insulated from each other.

• Wire cross sections of the supply cable from the cus-

tomer's power system should be designed in accordance

with the applicable standards.

If the supply voltage for the CLV61x is not supplied via the

optional CDB620 connection module, the CLV61x must

be protected by a separate max. 2 A slow-blow fuse at the

beginning of the supply circuit.

• In order to retain the IP 65 enclosure rating for the CLV61x

connecting cable even when using an extension cable

(e.g., no. 6034417, 2 m/6.56 ft), insert rubber seal no.

4038847 between the plug and socket of the D-Sub plug

connection of the cables and screw in the plug connection.

• Circuits connected to the CLV61x must be designed as

SELV circuits (SELV = Safety Extra Low Voltage).

a

DANGER

Risk of injury/risk of damage via electrical current!

The CLV61x is designed to be operated in a system with pro-

fessional grounding of all connected devices and mounting

surfaces to the same ground potential.

Incorrect grounding of the CLV61x can, due to equipotential

bonding currents between the CLV61x and other grounded

devices in the system, place the metal housing under a dan-

gerous voltage, cause malfunction and destruction of devices

as well as damage to the cable shielding through heating,

and thus cause cable fires.

• Work on the electrical system must only be performed by

qualified electricians.

• Ensure ground potential at all grounding points.

• In the event of damage to the cable insulation, immediately

switch off the power supply and have the damage repaired.

>

See the “

Electrical Installation

” chapter in the

&

“CLV61x

Bar Code Scanner” Technical Information

(no. 8015592)

on the product site on the web (

www.sick.com/CLV61x

) for

measures to eliminate hazards.

1. Connect the 15-pin D-Sub-HD plug of the CLV61x cable to

the CDB620 connection module.

2. Connect a read pulse sensor, such as a photoelectric sen-

sor at the “Sens 1” switching input of the CDB620.

See the “

Electrical Installation

” chapter in the

&

“

CLV61x

Bar Code Scanner” Technical Information

(no. 8015592).

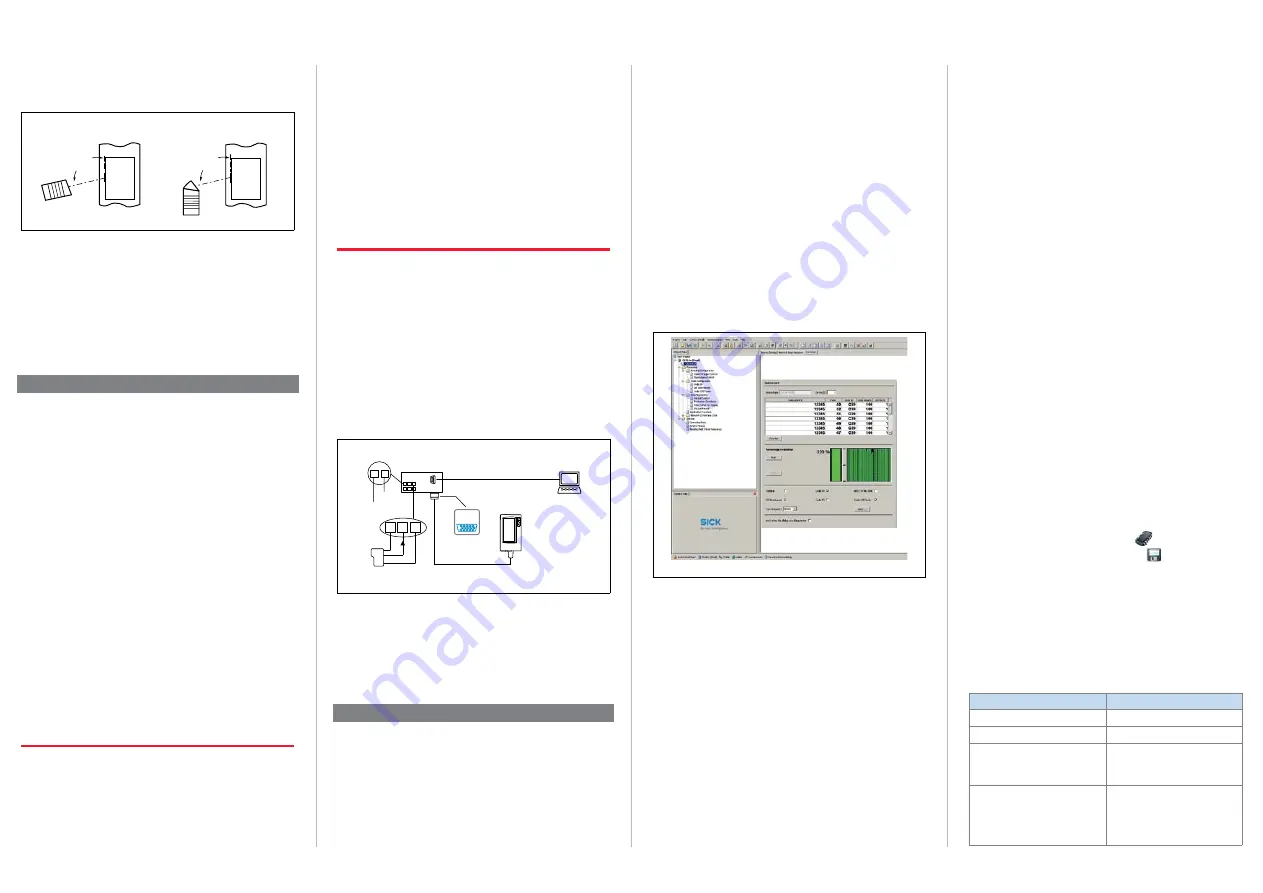

3. Connect the serial AUX interface (RS-232) of the CLV61x to

the PC (9-pin D-Sub plug) with a suitable data cable (e.g.,

no. 2014054, 2 m) using the internal plug “AUX” (9-pin

D-Sub) of the CDB620.

If the PC does not have an RS-232 interface, use a suit-

able adapter cable with RS-232 <> USB converter (e.g.,

no. 6042499, 1.5 m).

CDB620

Connection

Module

SOPAS

SOPAS

CLV61x

DC 10 V ... 30 V

GND

Configuration

Diagnosis

“HOST/AUX/I/O“

(RS-232)

Serial

Serial

...

...

1 2

11 10 12

Reading

clock

SGND

Sens 1

V

s

Aux

“AUX“ (

RS-232

)

e.g. cable no. 2014054

(2 m)

Electr. connection of the CLV61x for commissioning as a stand-alone device

4. Switch on the supply voltage for the CDB620 and the PC.

All LEDs on the CDB620 will light up briefly.

The CLV61x starts with a delay and uses the default

parameters set in the factory for the initialization. After a

successful self-test, the LED on the CLV61x lights up blue

to indicate the “Device Ready” status.

Step 3: Configuration with PC

User Modes and Statuses of the CLV61x:

• Quick Start (initial commissioning for read operation)

• Read operation

• Percentage evaluation (for diagnostic purposes)

•

Configuration via SOPAS ET configuration software

• Firmware download

Configuration

In case of error, the SOPAS ET configuration software is used

by default to adjust the CLV61x parameters to the application

and to the diagnostics.

Installing and Starting the Configuration Software

1. Download and install the SOPAS ET software on the PC

from the website “

www.sick.com/software”

. In this case,

select the “Complete” option as suggested by the install

wizard.

2.

Start “Standard” user interface for standalone applica

-

tions”.

3. Establish a connection between software and CLV61x e.g.,

via the serial AUX interface (57.6 kBd).

The connection wizard starts automatically. Under inter-

face selection, select the standard protocol.

4. Select the CLV61x from the devices that are now available

and displayed. The

Q

uick

S

tart

device page appears.

SOPAS ET Program Window

Device tree (left), device page

Q

uick

S

tart

(

right

)

User Level, Parameter Download

The user is automatically logged onto the CLV61x at user

level “Authorized Client” (password: client). The user can

change parameters, which will be immediately transferred to

the CLV61x (default). Initially they will have only temporary

effect there, without being saved, until the supply voltage is

switched off. If the parameters are to be retained, they must

be permanently saved (

a.

Configuration via the “Quickstart” Device Page

The “Quickstart” device page offers an overview of the most

important parameters and enables quick evaluation of code

content. Functions such as “Evaluation Window,” “Percentage

Evaluation,” “Code Configuration,” and “Scanning Frequency”

are available via the Quickstart.

Evaluation Window

The evaluation window shows the code content, the code

type, the increment index, the code security, and the device

number of the reading CLV61x.

Percentage Evaluation

The percentage evaluation permanently assesses the quality

of the reading. Bar codes are not assessed. Here, the bar

codes must not be subjected to any conveying movement.

The CLV61x performs 100 scans in each case and evaluates

the reading quality. The CLV61x continuously emits read

results every 2 s via the AUX interface, together with the read

diagnostic data.

Code Configuration

In the factory default setting, the CLV61x decodes the follow-

ing code types:

• Code 39

• Interleaved 2 of 5

• Code 128 family

To activate or deactivate further code types:

Device tree > Parameters > Code configuration.

b. Summary of Further Useful Adaptation Options

Object Trigger Control

The CLV61x can, as described in the standard application,

be operated with a connected read pulse sensor, such as a

photoelectric sensor on the “Sensor 1” switching input. To

select a different pulse type or switching input:

Device tree > Parameters > Object trigger control.

c.

Completing the Configuration

>

Permanently save the entire configuration:

Parameter set in CLV61x: click the

button

Configuration file on the PC: click the

button.

Important!

In order to commission the CLV61x CAN or FIELDBUS series

in the SICK CAN scanner network together with further SICK

products, select the “Advanced” user interface when starting

the configuration software program. Path: Start > Programs >

SICK > SOPAS ET Engineering Tool > SOPAS.

The “Standard” user interface option is not suitable for this.

Default Setting CLV61x (Summary)

Parameter

Value

Scanning frequency

500 Hz

Laser timeout

No

Code length

Free

(max. 1,500 characters in read-

ing interval across all measured

codes)

Reading trigger

Read operation:

Start: Sensor 1 switching input

Stop: Sensor 1 switching input

Quick Start:

START and STOP buttons for

percentage evaluation