13

ASSEMBLY

NOTE:

For "non-thru cuts", lower the riving knife to the “non-

thru cut” position using the same procedure. In this case the

“non-thru cut" position line should be parallel to and level with

the table.

WEAR

WEAR

PLATE

PLATE

Figure 7

Refer to Fig. 5 & 6.

This saw is shipped with its riving knife

(E)

installed in the

lowered or “non-thru cut” position. This riving knife matches

the thickness of the blade that is shipped with your saw. To

install the anti-kickback pawls and the blade guard assembly,

first raise the riving knife from the lowered or “non-thru cut”

position to the raised or "

thru

cut" position, as follows:

1.

With the blade assembly to the highest possible

position, carefully reach alongside the blade and raise

the riving knife locking lever up to unlock the riving

knife.

2.

Gently move the riving knife to the right to release it

from the lock pins in the riving knife assembly.

3.

Slide the riving knife up and forward until you feel

the lock pins engage the riving knife in the “thru cut”

position. When properly aligned in this position, the

“thru cut" position line on the riving knife will be parallel

to and level with the table.

4.

Return the riving knife lock lever to the lock position.

5.

Make sure the riving knife is securely installed and

properly aligned with the blade.

Figure 6

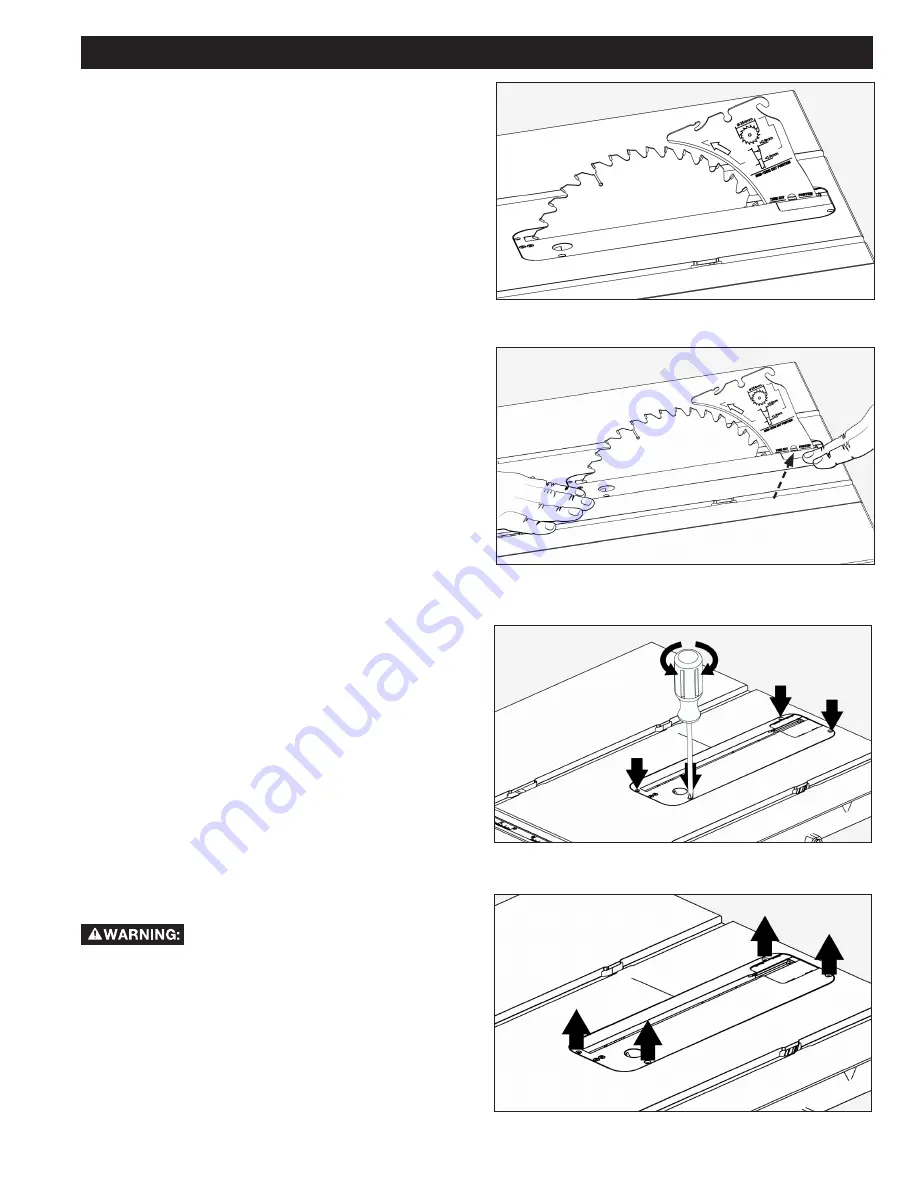

INSERT AND LEVEL THROAT

PLATE

Insert the rear tab of the throat plate (G) (the end with the

wear plates) under the surface of the table, and snap the front

end in place (Fig. 7).

Check that the throat plate is properly adjusted to the table.

Front of throat plate should be level or slightly below the

surface of the table and rear of the throat plate should be level

or slightly above the surface of the table (Fig. 7).

If adjustment is needed, adjust the (4) Phillips set screws

(Fig.

8A)

up or down as needed. Repeat this process as needed until

the throat plate is level.

To remove throat plate, lower blade below tabletop, then

carefully slide the throat plate from out from the rear of the

table to the front, keeping the blade centered within the slot

on the throat plate. (Fig. 8B)

It is important that the throat plate is

properly adjusted to the table. This ensures

that the work piece is not caught on the throat plate or the

table when feeding the work piece through the blade during a

cut.

Figure 8A

Figure 8B

NOTE:

Zero clearance throat plate inserts are available online.

NOTE:

No portion of table insert shall be above or more than

0,7 mm below the plane of the table top surface at the infeed

side and no portion of the table insert is below or more than

0,7 mm above the plane of the table top at the out-feed side.