2. After electric pump is normally used for 2000 hours, it shall be sent to qualified

maintenance stations for maintenance by the following steps:

Disassembly: Check wearing parts, e.g. rolling bearing, mechanical seal, and impeller,

which shall be replaced if damaged.

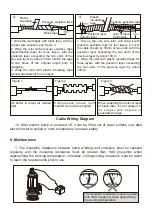

Air pressure test: After electric pump is disassembled for repair or a seal is replaced,

the motor cavity and seal cavity must be subjected to air pressure test, the test pressure is

0.2Mpa (megohm), and no leakage or sweating shall occur in a duration of 3min.

Oil replacement: Unscrew the oiling screw at oil chamber, and replace used oil with

No.10 white oil for food-level machinery to reach 95% volume of chamber.

3. If electric pump is not used for a long time, it should not be immersed in the water;

electric pump shall be placed in clean water to run several minutes, cleaned to remove

coagulations inside and outside the pump, dried, subjected to anti-rust treatment, and

placed at dry and ventilated place. Electric pump which has been used for a long time shall

be repainted and subjected to anti-rust treatment depending on its surface corrosion

situation.

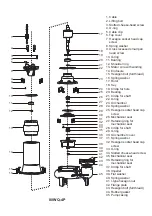

Check wearing parts after

2000 hours of operation

Impeller

Mechanical seal

Bearing

Impeller

Bearing

Mechanical seal

When electric pump is not in use,

it shall be cleaned to remove

coagulations on the surface and

dried, and subjected to anti-rust

treatment.