5

7. WELDING coated electrodes (MMA)

7.1. Preparing device and Equipment for work

7.1. Preparing device and Equipment for work

7.1. Preparing device and Equipment for work

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

Ko ñ welding cables should tip with s connected and whether Æ the seats (12) and (13) located and radiant ę on the front panel so that the electrode holder

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

was a ę WŁA ś competent for the electrode pole. Clamp the second cable should with be carefully fasten Æ on the material workpiece. connect and whether Æ plug

ę device and device to a wall socket 3x400V 50Hz.

ę device and device to a wall socket 3x400V 50Hz.

ę device and device to a wall socket 3x400V 50Hz.

ę device and device to a wall socket 3x400V 50Hz.

7.2. Setting the welding parameters

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

knob ę Background (10) set C. dan and worth SC pr and the welding. Recommended parameters pr and ent to most-welding rts species commonly

used in the electrode shown in the table:

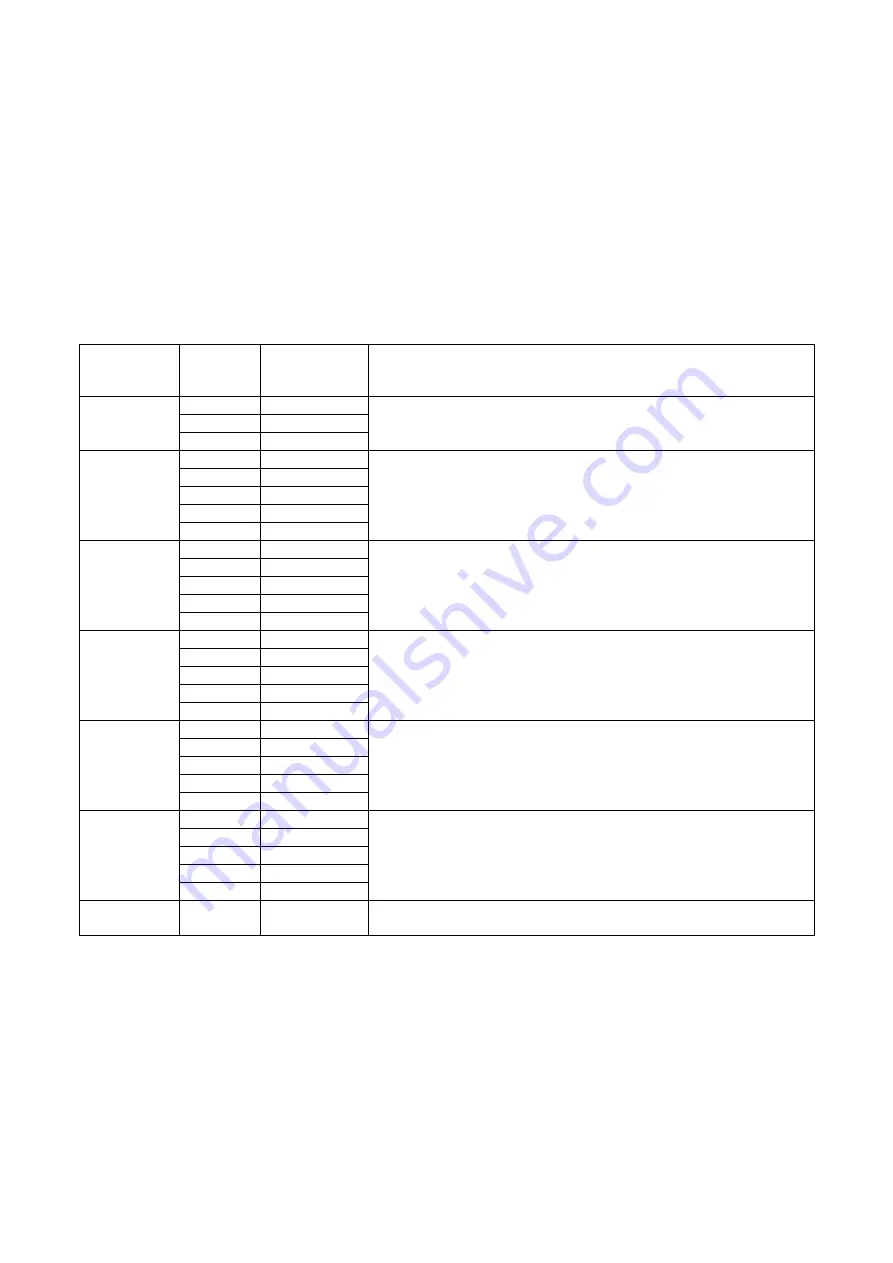

marking

electrodes

Ś diameter

Ś diameter

electrodes

[Mm]

recommended pr and welding

recommended pr and welding

recommended pr and welding

current [A]

Application

ER 142

2

40 - 60

Welding of steel, for example .: St0S, St1S, St2S, St3Sx, and similar St4Sx mostly thin

sheets

2.5

60 - 90

3.25

100 - 150

ER 146

2

40 - 60

Welding steel, e.g. .: St0S, St1S, St2S, St3Sx, St4Sx and the like mainly of sheet metal

tubular steel grade and R 35

2.5

50 - 80

3.25

80 - 130 4

120 - 180 5

160 - 230

ER 346

2

45 - 80

Welding steel, e.g. .: St0S, St1S, St2S, St3Sx, St4Sx and the like mainly of sheet metal

tubular steel grade R, R 35, R 45, round steel ę towych St41, St41A, St41D, St1KO,

tubular steel grade R, R 35, R 45, round steel ę towych St41, St41A, St41D, St1KO,

tubular steel grade R, R 35, R 45, round steel ę towych St41, St41A, St41D, St1KO,

St45KO, boiler steel St41k, St45k, St36P, St36X

2.5

60 - 110

3.25

100 - 150 4

150 - 200 5

180 - 250

EB 146

2

50 - 75

St0S steel welding, St1S, St2S, St3SX, St4S, St4SX, round steel ę towych St41, St41A,

St0S steel welding, St1S, St2S, St3SX, St4S, St4SX, round steel ę towych St41, St41A,

St0S steel welding, St1S, St2S, St3SX, St4S, St4SX, round steel ę towych St41, St41A,

St41D, St1KO, St45KO, steel pipe

R, R35, R45, K10, K18, boiler steel St36K, St45K, St36P, St36X, K22H and steel of

increased with withstand elevated ś you gat. 09G2, 18G2, etc. 18G2A.

increased with withstand elevated ś you gat. 09G2, 18G2, etc. 18G2A.

increased with withstand elevated ś you gat. 09G2, 18G2, etc. 18G2A.

increased with withstand elevated ś you gat. 09G2, 18G2, etc. 18G2A.

increased with withstand elevated ś you gat. 09G2, 18G2, etc. 18G2A.

2.5

70 - 100

3.25

100 - 140 4

140 - 190 5

180 - 250

EA 146

2

40 - 70

St0S steel welding, St1S, St2S, St3SX, St4S, St4SX, round steel ę towych St41, St41A,

St0S steel welding, St1S, St2S, St3SX, St4S, St4SX, round steel ę towych St41, St41A,

St0S steel welding, St1S, St2S, St3SX, St4S, St4SX, round steel ę towych St41, St41A,

St41D, St1KO, St45KO, steel pipe

R, R35, R45, etc.

2.5

50 - 100

3.25

90 - 130 4

140 - 200 5

180 - 240

E WITH M (-)

E WITH M (-)

E WITH M (-)

2

30 - 60

Welding with cast cold

Welding with cast cold

Welding with cast cold

2.5

50 - 80

3.25

80 - 120 4

110 - 170 5

150 - 200

E WITH Fe, Ni

E WITH Fe, Ni

E WITH Fe, Ni

3.25

75 - 100

Welding with cold iron, in some cases as with

Welding with cold iron, in some cases as with

Welding with cold iron, in some cases as with

Welding with cold iron, in some cases as with

nickel

7.3. initiation arc

Initiation of arc welding electrodes and wrapped and It involves affected ę five of the electrode to the workpiece, and short rubbed isolation. In the case of

Initiation of arc welding electrodes and wrapped and It involves affected ę five of the electrode to the workpiece, and short rubbed isolation. In the case of

Initiation of arc welding electrodes and wrapped and It involves affected ę five of the electrode to the workpiece, and short rubbed isolation. In the case of

Initiation of arc welding electrodes and wrapped and It involves affected ę five of the electrode to the workpiece, and short rubbed isolation. In the case of

Initiation of arc welding electrodes and wrapped and It involves affected ę five of the electrode to the workpiece, and short rubbed isolation. In the case of

Initiation of arc welding electrodes and wrapped and It involves affected ę five of the electrode to the workpiece, and short rubbed isolation. In the case of

Initiation of arc welding electrodes and wrapped and It involves affected ę five of the electrode to the workpiece, and short rubbed isolation. In the case of

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

initiation of the arc electrodes which hardens after lagging ę forms a five Deenergized and cy with at with El should with s ribbon, ę then eyes ś these Æ the tip

of the electrode by repeated impact on a hard and

of the electrode by repeated impact on a hard and

surface ę and with to obtain metal contact with the work piece.

surface ę and with to obtain metal contact with the work piece.

surface ę and with to obtain metal contact with the work piece.

surface ę and with to obtain metal contact with the work piece.

surface ę and with to obtain metal contact with the work piece.

8. WELDING ELECTRODE AND infusible ¥ ( METHOD TIG)

8. WELDING ELECTRODE AND infusible ¥ ( METHOD TIG)

8. WELDING ELECTRODE AND infusible ¥ ( METHOD TIG)

8. WELDING ELECTRODE AND infusible ¥ ( METHOD TIG)

8. WELDING ELECTRODE AND infusible ¥ ( METHOD TIG)

8.1. Preparing device and Equipment for work

8.1. Preparing device and Equipment for work

8.1. Preparing device and Equipment for work