18

PRECISION MACHINE TOOLS

Maintenance Manual

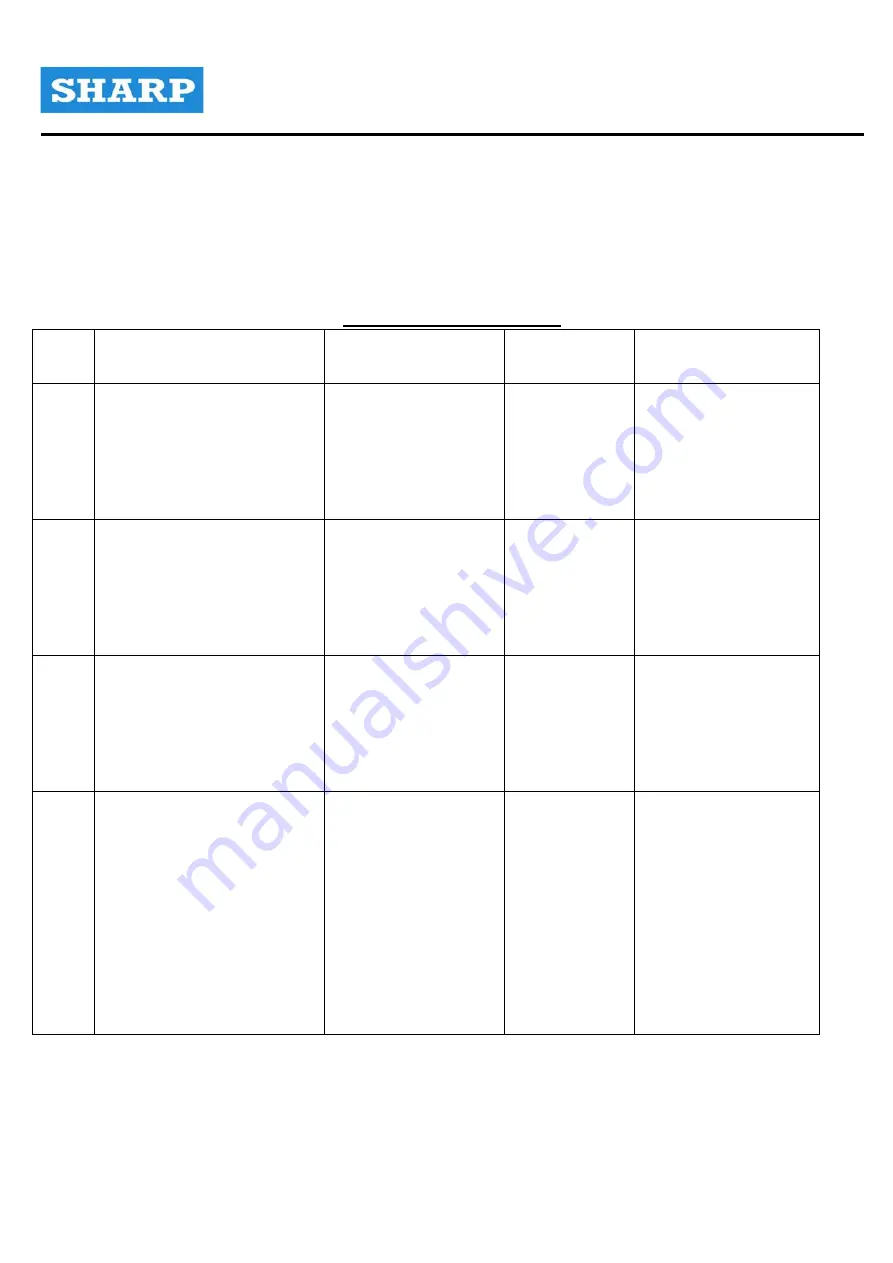

2-3 Spindle Warm-up

This is an aerosol lubrication design, and so before turning on the machine, follow the warm-up steps

below to extend the lifespan of the spindle and to avoid damaging the bearing by letting the oil aerosol

getting into the bearing ahead

.

Spindle warm-up time

Item Condition

Spindle RPM

(Maximum RPM %)

Rotation Time

( min )

Check Contents

1

Routine operation

Max Rpm 20%

10

1. Less than 10°C

increase of

temperature

2. Shocks

3. Noises

2

If the spindle has been

stopped for more than two

hours, warm-up is

compulsive.

20% 10

1. Less than 10°C

increase of

temperature

Shocks

2. Noises

3

Spindle stopped for more

than 72 hours

1. 20%

2. 50%

10

10

1. Less than 10°C

increase of

temperature

2. Shocks

3. Noises

4

Spindle stopped for more

than 2 weeks

1. 500 RPM

2. 20%

3. 40%

4. 60%

5. 80%

6. Maximum RPM

60

10

10

*10

*10

*10

Less than 10°C

increase of

temperatureShocks

Noises

4. Do not go onto the

next step until the

temperature has

become stable.

Содержание SVX500

Страница 1: ...1 PRECISION MACHINERY TOOLS SVX500 MAINTENANCE MANUAL ...

Страница 3: ...3 PRECISION MACHINE TOOLS Maintenance Manual Chapter 1 Routine Maintenance ...

Страница 7: ...7 PRECISION MACHINE TOOLS Maintenance Manual 1 2 Spindle unit 1 2 Spindle unit 14 15 ATC system ...

Страница 8: ...8 PRECISION MACHINE TOOLS Maintenance Manual Machine precision check 20 21 ...

Страница 9: ...9 PRECISION MACHINE TOOLS Maintenance Manual 23 Oil skimmer 18 19 EC cabinet ...

Страница 14: ...14 PRECISION MACHINE TOOLS Maintenance Manual Chapter 2 The Spindle Unit ...

Страница 16: ...16 PRECISION MACHINE TOOLS Maintenance Manual 2 2 Tool Shank and Broach Bolts ...

Страница 17: ...17 PRECISION MACHINE TOOLS Maintenance Manual CAT 40 STUD ...

Страница 22: ...22 PRECISION MACHINE TOOLS Maintenance Manual Chapter 3 The Air Compressor Unit ...

Страница 23: ...23 PRECISION MACHINE TOOLS Maintenance Manual 3 1 Air compressor system layout ...

Страница 24: ...24 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 25: ...25 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 26: ...26 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 27: ...27 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 30: ...30 PRECISION MACHINE TOOLS Maintenance Manual Chapter 4 The Lubrication Unit ...

Страница 31: ...31 PRECISION MACHINE TOOLS Maintenance Manual 4 1 Centralized Lubrication System Diagarm ...

Страница 32: ...32 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 33: ...33 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 34: ...34 PRECISION MACHINE TOOLS Maintenance Manual Chapter 5 The Spindle Oil Cooling Unit ...

Страница 35: ...35 PRECISION MACHINE TOOLS Maintenance Manual 5 1 Spindle Oil Cooling Pipeline Diagram ...

Страница 36: ...36 PRECISION MACHINE TOOLS Maintenance Manual Chapter 6The Electrical Unit ...

Страница 40: ...40 PRECISION MACHINE TOOLS Maintenance Manual Chapter 7 Appendix ...

Страница 42: ...42 PRECISION MACHINE TOOLS Maintenance Manual 7 2 Descriptions on Program and Servo Alarms ...

Страница 43: ...43 PRECISION MACHINE TOOLS Maintenance manual ...

Страница 44: ...44 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 45: ...45 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 46: ...46 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 47: ...47 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 48: ...48 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 49: ...49 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 50: ...50 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 51: ...51 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 52: ...52 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 53: ...53 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 54: ...54 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 55: ...55 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 56: ...56 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 57: ...57 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 58: ...58 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 59: ...59 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 60: ...60 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 61: ...61 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 62: ...62 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 63: ...63 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 64: ...64 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 65: ...65 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 66: ...66 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 67: ...67 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 68: ...68 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 69: ...69 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 70: ...70 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 71: ...71 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 72: ...72 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 73: ...73 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 74: ...74 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 75: ...75 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 76: ...76 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 77: ...77 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 78: ...78 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 79: ...79 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 80: ...80 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 81: ...81 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 82: ...82 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 83: ...83 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 84: ...84 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 85: ...85 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 86: ...86 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 87: ...87 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 88: ...88 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 89: ...89 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 90: ...90 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 91: ...91 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 92: ...92 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 93: ...93 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 94: ...94 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 95: ...95 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 96: ...96 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 97: ...97 PRECISION MACHINE TOOLS Maintenance Manual 7 3 List of the Machine Components 1 Bed ...

Страница 98: ...98 PRECISION MACHINE TOOLS Maintenance Manual BED PIPING ...

Страница 99: ...99 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 100: ...100 PRECISION MACHINE TOOLS Maintenance Manual 2 X SADDLE ...

Страница 101: ...101 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 102: ...102 PRECISION MACHINE TOOLS Maintenance Manual 3 X AXIS DRIVE ...

Страница 103: ...103 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 104: ...104 PRECISION MACHINE TOOLS Maintenance Manual 4 X SCALE ...

Страница 105: ...105 PRECISION MACHINE TOOLS Maintenance Manual 5 X Y PIPING ...

Страница 106: ...106 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 107: ...107 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 108: ...108 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 109: ...109 PRECISION MACHINE TOOLS Maintenance Manual 6 Y SADDLE ...

Страница 110: ...110 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 111: ...111 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 112: ...112 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 113: ...113 PRECISION MACHINE TOOLS Maintenance Manual 7 Y PIPING ...

Страница 114: ...114 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 115: ...115 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 116: ...116 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 117: ...117 PRECISION MACHINE TOOLS Maintenance Manual 8 Y SCALE ...

Страница 118: ...118 PRECISION MACHINE TOOLS Maintenance Manual 9 Y DRIVER ...

Страница 119: ...119 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 120: ...120 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 121: ...121 PRECISION MACHINE TOOLS Maintenance Manual 10 Z SADDLE ...

Страница 122: ...122 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 123: ...123 PRECISION MACHINE TOOLS Maintenance Manual 11 Z PIPING ...

Страница 124: ...124 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 125: ...125 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 126: ...126 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 127: ...127 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 128: ...128 PRECISION MACHINE TOOLS Ver 1 Maintenance Manual ...

Страница 129: ...129 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 130: ...130 PRECISION MACHINE TOOLS Maintenance Manual 12 Z SCALE ...

Страница 131: ...131 PRECISION MACHINE TOOLS Maintenance Manual 13 Z DRIVER ...

Страница 132: ...132 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 133: ...133 PRECISION MACHINE TOOLS Maintenance Manual 14 A DRIVER L ...

Страница 134: ...134 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 135: ...135 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 136: ...136 PRECISION MACHINE TOOLS Ver 1 Maintenance Manual ...

Страница 137: ...137 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 138: ...138 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 139: ...139 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 140: ...140 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 141: ...141 PRECISION MACHINE TOOLS Maintenance Manual 15 A DRIVER R ...

Страница 142: ...142 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 143: ...143 PRECISION MACHINE TOOLS Maintenance Manual 16 A PIPING ...

Страница 144: ...144 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 145: ...145 PRECISION MACHINE TOOLS Maintenance Manual 17 C TABLE ...

Страница 146: ...146 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 147: ...147 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 148: ...148 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 149: ...149 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 150: ...150 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 151: ...151 PRECISION MACHINE TOOLS Maintenance Manual 18 C PIPING ...

Страница 152: ...152 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 153: ...153 PRECISION MACHINE TOOLS Maintenance Manual 19 C DRIVER ...

Страница 154: ...154 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 155: ...155 PRECISION MACHINE TOOLS Maintenance Manual 20 ATC DOOR ...

Страница 156: ...156 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 157: ...157 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 158: ...158 PRECISION MACHINE TOOLS Maintenance Manual 21 COOLER ...

Страница 159: ...159 PRECISION MACHINE TOOLS Maintenance Manual 22 FOUNDATION ...

Страница 160: ...160 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 161: ...161 PRECISION MACHINE TOOLS Maintenance Manual 23 HYDRAULIC ...

Страница 162: ...162 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 163: ...163 PRECISION MACHINE TOOLS Maintenance Manual 24 LUBRICATION ...

Страница 164: ...164 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 165: ...165 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 166: ...166 PRECISION MACHINE TOOLS Maintenance Manual 25 PNEUMATIC ...

Страница 167: ...167 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 168: ...168 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 169: ...169 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 170: ...170 PRECISION MACHINE TOOLS Maintenance Manual ...

Страница 171: ...171 PRECISION MACHINE TOOLS Maintenance Manual ATC ...

Страница 173: ...173 PRECISION MACHINE TOOLS Maintenance Manual CAM BOX ...

Страница 175: ...175 PRECISION MACHINE TOOLS Maintenance Manual ...