AYXPC18LR

3 – 3

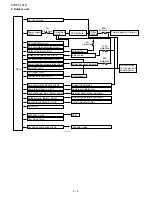

:Flashes

in

2-sec

intervals

(normal)

:O

n

:Off

:Flashes

3

times

in

0.2-sec

intervals

Status

of

indoor/ outdoor

units

Indication by

LED

on

outdoor unit

Indication

by

operation

lamp

on

indoor

unit

Content

of

diagnosis

Main

category

Sub-category

(1)

Check

the

connector

of

the

outdoor

unit

thermistor

for

secure

installation.

(2)

Measure

resistance

of

the

outdoor

ther-

mistor.

(3)

Check

the

lead

wire

of

the

outdoor

unit

thermistor.

(4)

No

abnormality

found

in

above

inspec-

tions

(1)

through

(3).

(1)

IPM

continuity

check

(2)

Check

the

IPM

and

heat

sink

for

secure

installation.

(3)

C

heck

the

outdoor

unit

fan

motor

for

proper

rotation.

(4)

No

abnormality

found

in

above

inspec-

tions

(1)

through

(3).

(5)

No

abnormality

found

in

above

inspec-

tions

(1)

through

(4).

(1)

Check

the

outdoor

unit

air

outlet

for

blockage.

(2)

Check

the

outdoor

unit

fan

for

proper

rotation.

(1)

C

heck

the

outdoor

unit

air

outlet

for

blockage.

(2)

Check

the

outdoor

unit

fan

for

proper

rotation.

(1)

Check

if

there

is

an

open-circuit

in

the

secondary

winding

of

the

current

trans-

former

of

the

outdoor

unit

control

PWB.

(2)

Check

if

the

refrigerant

volume

is

abnor-

mally

low.

(3)

Check

if

the

refrigerant

flows

properly.

(1)

Correct

the

installation.

(2)

Replace

the

outdoor

unit

thermistor

assembly.

(3)

Replace

the

outdoor

unit

thermistor

assembly.

(4)

R

eplace

the

outdoor

unit

control

PWB

assembly.

(1)

R

eplace

the

outdoor

unit

control

PWB

assembly.

(2)

Correct

the

installation

(tighten

the

screws).

Apply

silicon

grease.

(3)

Replace

the

outdoor

unit

fan

motor.

(4)

R

eplace

the

outdoor

unit

control

PWB

assembly.

(5)

Replace

the

compressor.

(1)

Ensure

unobstructed

air

flow

from

the

outdoor

unit

air

outlet.

(2)

Check

the

outdoor

unit

fan

motor.

(1)

Ensure

unobstructed

air

flow

from

the

outdoor

unit

air

outlet.

(2)

Check

the

outdoor

unit

fan

motor.

(1)

Replace

the

outdoor

unit

control

PWB

assembly.

(2)

Charge

the

specified

amount

of

refriger

-

ant.

(3)

Correct

refrigerant

clogs.

(2-way

valve,

3-way

valve,

pipe,

expansion

valve)

Inspection

location/method

Remedy

Heat

exchanger

thermistor

open

-

circuit

error

Outdoor

tempera-

ture

thermistor

open

circuit

error

Suction

thermistor

open-circuit

error

Discharge

thermis

-

tor

open

circuit

error

DC

overcurrent

er

-

ror

AC

overcurrent

er

-

ror

AC

maximum

cur

-

rent

error

AC

current

defi

-

ciency

error

Lighting

pattern

at

the

time

of

timer

lamp

lighting

Off

for

5

seconds

Operation

lamp

Cluster

lamp

Operation

lamp

Cluster

lamp

Operation

lamp

Cluster

lamp

Operation

lamp

Cluster

lamp

Operation

lamp

Cluster

lamp

Operation

lamp

Cluster

lamp

Operation

lamp

Cluster

lamp

Operation

lamp

Cluster

lamp

Outdoor

unit

thermistor short-circuit

Outdoor

unit

DC

Outdoor

unit

AC

5

time

6

time

7

time

9

time

Indoor/ outdoor

units

in

complete

shutdown

*3:

The

content

of

diagnosis

is

transferred

to

the

indoor

unit

via

serial

communication,

but

it

does

not

trigger

a

complete

shutdown

operation.

Number

of

repetition

°:

No

complete

shutdown

Main

category

Sub

category

Malfunction

No.

50

1

2

4

60

70

0

3

1

4

2

3

Operation

lamp

Clus

te

rl

amp

4

way

valve

err

or

or

Gas

leak

error

(1)

C

heck

to

make

sur

e

outdoor

unit

ther

mi

stor

TH

2(

ex

ch

ange)

and

TH

3(

pi

pe

temperature)

are

instal

led

in

correct

portions.

(2)

Ch

eck

if

th

er

efi

geran

tv

olum

e

is

abnomall

yl

ow

.

(3)

C

heck

the

4-w

ay

valve

for

proper

op

eration

.

(1)

Correct

the

in

sta

llation.

(2)

Change

the

speccified

amount

of

refrigerant.

(3)

Replac

e

the

4-way

va

lv

e.

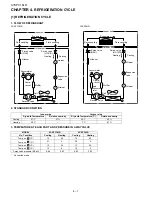

Cyc

le

tem

perature

AC

overcurrent

er

-

ror

in

OFF

status

(1)

IPM

continuity

check

(1)

Replace

the

outdoor

unit

control

PWB

assembly.

Operation

lamp

Cluster

lamp

Outdoor

unit

cooling/heating switchover

Thermistor

install-

tion

error

or

4-way

valve

error

(1)

Check

to

make

sure

outdoor

unit

thermistor

TH2

(heat

exchanger)

and

TH

(2-way

valve)

are

installed

in

correct

posittions.

(2)

Measure

resistance

of

thermistor

TH1

and

TH5.

(3)

Check

the

4-way

valve

for

proper

operation.

(4)

No

abnormality

found

in

above

inspections

(1)

through

(3)

(1)

Correct

the

installation.

(2)

Replace

the

thermistor

assembly.

(3)

Replace

the

4-way

valve.

(4)

Replace

the

outdoor

unit

control

PWB

assembly.

Operation

lamp

Cluster

lamp

Torque

control

error

(1)

Check

if

the

refrigerant

volume

is

abnormally

low.

(2)

Check

the

4-way

valve

for

proper

operation.

(3)

Check

to

see

compressor

type

is

correct

(1)

Change

the

speccified

amount

of

refrigerant.

(2)

Replace

the

4-way

valve.

(3)

Replace

the

compressor

with

correct.

Operation

lamp

Cluster

lamp

Содержание AE-X18LR

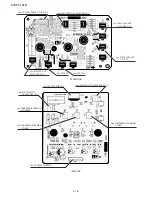

Страница 4: ...AYXPC18LR 1 3 2 EXTERNAL DIMENTIONS 1 Indoor unit 222 325 1040 Remote controller 204 57 18 ...

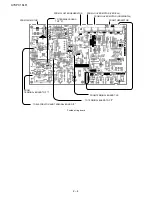

Страница 9: ...AYXPC18LR 2 3 2 MICROCOMPUTER CONTROL SYSTEM 1 Indoor unit ...

Страница 38: ...AYXPC18LR 5 10 ...

Страница 52: ... 1 EndPage ...