SC901P

9

8

SC901P

2 . P R E P A R AT I O N

Remove the compressor from its

packaging and inspect for any damaged

parts. If anything is found to be missing or

damaged, please contact SGS.

Take care when transporting the

compressor, do not overturn it or lift it with

hooks or ropes.

Position the compressor on a flat, level sur-

face or with a maximum permissible inclina-

tion of 10°.

Place in a well-ventilated area.

If the surface is inclined and smooth, check

if the compressor moves whilst in operation.

If the surface is in a raised position, make

sure the compressor cannot fall, securing it

in a suitable way.

To ensure good ventilation and efficient

cooling, the compressors belt guard must

be at least 200cm from any wall.

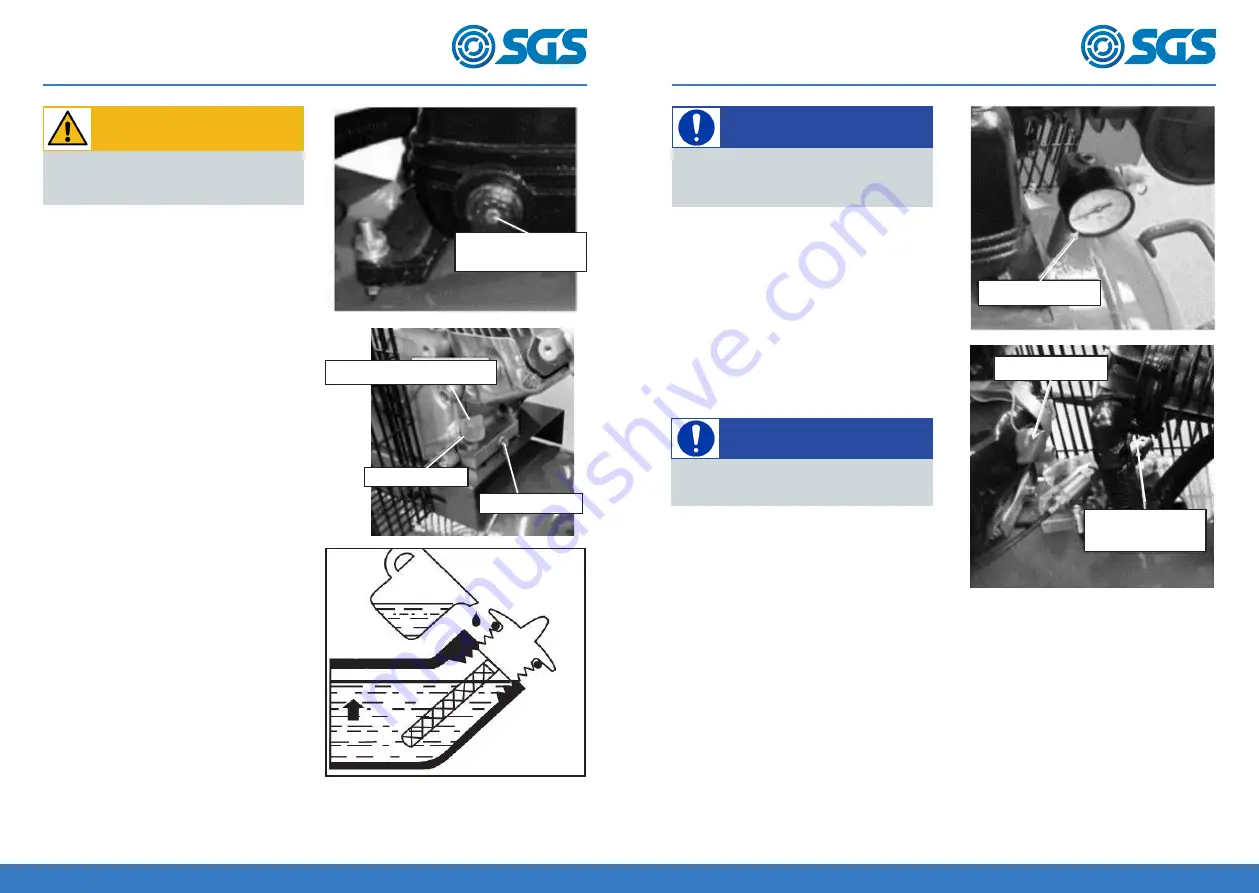

Before using the compressor,

check the oil level by looking at

the sight gauge as shown below.

If the oil is not between the minimum and

maximum mark, it should be topped up.

We do not recommend using mineral oil in

the compressor.

WARNING

Seek assistance when removing the

compressor from its packaging.

Fill oil to this level

Check the engine oil level. It should be

filled with semi-synthetic SAE 15W40 en-

gine oil to the top of the filler neck.

Oil filler Cap / Dipstick

Oil filler neck

Oil drain plug

3 . S TA R T I N G P R O C E D U R E

NOTE

ALWAYS check the engine oil and pump

oil before starting. Severe engine or pump

damage may otherwise result.

1. Check that the air outlet valve on the

tank end-plate is closed.

2. Ensure that the engine oil is topped up.

3. Turn the ignition switch to the ON po-

sition and move the choke lever to half way.

4. Pull the recoil start handle until you feel

resistance and then pull swiftly until the en-

gine starts.

5. Once running, move the choke to the

OFF position.

When the engine is running

smoothly, the compressor will operate

automatically, building up the pressure in

the tank, which is shown on the pressure

gauge to the maximum setting (factory set).

When the maximum tank pres-

sure is reached, the relief valve will

automatically vent the pump

output. When the tank pressure falls be-

low the minimum threshold (approx.

2bar/29psi less than the maximum

pressure), the relief valve will automat-

ically close and the tank pressure will

increase back to its maximum.

Pressure gauge

Ignition switch

Pressure relief

valve

NOTE

DO NOT allow the starter handle snap

back; gently return it.

To stop the compressor, simply turn the

ignition switch to the OFF position.