Page 8

OPERATION

APPLICATIONS

(Use only for the purposes listed below)

1. Sanding on wood surfaces.

2. Removing rust from and sanding steel surfaces.

WARNING:

Do not wear loose clothing or jewelry when operating

sander. They could get caught in moving parts causing

serious injury. Keep head away from sander and sanding

area. Hair could be drawn into sander causing serious

injury.

TO OPERATE

Clamp or otherwise secure the work to prevent it from

moving under your sander.

WARNING:

Unsecured work could be thrown towards the operator

causing injury.

Hold your sander in front and away from you, keeping it clear

of the workpiece. Start your sander by pressing the switch to

ON position and letting the motor build to its maximum

speed. Gradually lower your sander on the work with a slight

forward movement.

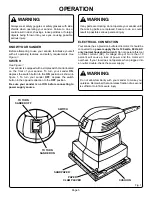

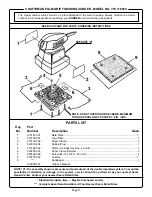

See Figure 4. Move it slowly using

forward and backward strokes.

DO NOT FORCE. The weight of the unit supplies adequate

pressure, so let the sanding sheet and sander do the work.

Applying additional pressure only slows the motor, rapidly

wears sandpaper and greatly reduces sander speed.

Excessive pressure will overload the motor causing possible

damage from motor overheating and can result in inferior

work. Any finish on resin or wood may soften from the

frictional heat. Do not allow sanding on one spot too long as

the sander's rapid action may remove too much material,

making the surface uneven. Always lift your sander from

workpiece before turning off.

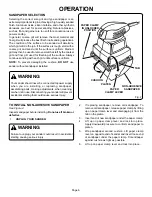

Flush sanding can be performed with your sander. As shown

in figure 5, the front edge of your sander allows flush sanding

in corners. The two side edges can also be used when

sanding in corners. Always remove sander from workpiece

before turning your sander off.

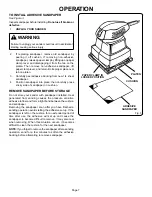

ORBITAL MOTION

Orbital motion is ideal for fast cutting action when removing

old finishes, smoothing rough wood, cutting stock down to

required dimensions or for finishing surfaces to be painted.

As shown in Figure 6, the sandpaper moves in tiny circles at

a very high speed, allowing the sander to move easily.

Fig. 6

Fig. 4

ORBITAL MOTION

Fig. 5