3.1. Air Supply

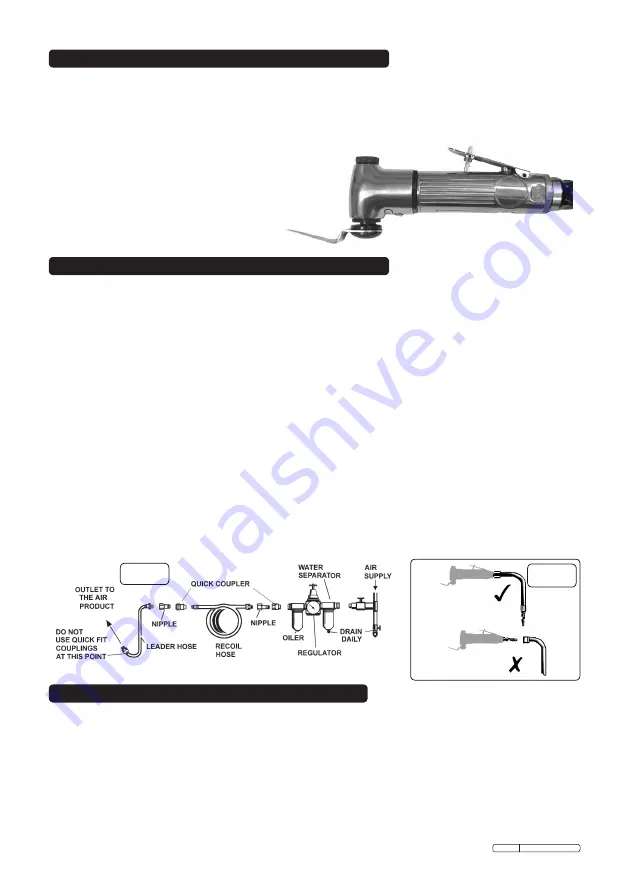

Recommended hook-up procedure is shown in fig 1.

3.1.1. Ensure tool air valve (or trigger) is in "Off" position before connecting to the air supply.

3.1.2. You will require an air pressure of 90psi, and an air flow according to specification.

3.1.3.

WARNING!

Ensure the air supply is clean and does not exceed 90psi while operating the

tool. Too high an air pressure and unclean air will shorten the product life due to

excessive wear, and may be dangerous causing damage and/or personal injury.

3.1.4. Drain the air tank daily. Water in the air line will damage the tool.

3.1.5. Clean air inlet filter weekly.

3.1.6. Line pressure should be increased to compensate for unusually long air hoses (over 8

metres). The minimum hose diameter should be 1/4” I.D. and fittings must have the same

inside dimensions.

3.1.7. Keep hose away from heat, oil and sharp edges. Check hose for wear, and make certain

that all connections are secure.

3.2. Couplings.

Vibration may cause failure if a quick change coupling is connected directly to the tool.

To overcome this, connect a leader hose to the tool. A quick change coupling may

then be used to connect the leader hose to the air line recoil hose. See fig 1 & 2.

3.

PREPARING TOOL FOR USE

4. OPERATING INSTRUCTIONS

fig 1

fig 2

2.

INTRODUCTION & SPECIFICATION

Blade frequency . . . . . . . . . . . . . 367Hz

Blade size. . . . . . . . . . . . . . . . . . 57mm

Air consumption . . . . . . . . . . . 10.6cfm

Operating pressure. . . . . . . . . . . . 90psi

Weight . . . . . . . . . . . . . . . . . . . . 1.4kg

Inlet. . . . . . . . . . . . . . . . . . . . . .1/4”BSP

Quickly and easily cuts windscreen bonding. Safety throttle prevents inadvertant starting and

features integral regulator for speed control. Exhaust is ducted away from work and operator. A

range of optional blades is available increasing the versatility of the knife in garage and workshop.

Supplied with offset straight blade and hex key.

4.1.

FITTING A BLADE

WARNING!

Disconnect from the air supply before changing blades.

4.1.1. Use hex key to remove retaining screw (Item 9B on parts diagram) and retaining spacer (9A).

4.1.2. Place the blade onto the spindle.

4.1.3. Replace the spacer and screw and secure with hex key, but do not over tighten.

Check that replacement blade is not damaged, (cracks, deformations etc).

Also check the mounting washer to ensure it is not deformed, burred or notched.

Original Language Version

WK025 Issue: 2 - 11/11/09