7.3.

Turning feed roller

IMPORTANT:

Turn the feed roller to suit the wire size.

There are two grooves on the feed roller, 0.6mm and 0.8mm. Always have the groove that is being

used on the outside of the roller (nearest to you). To turn the feed roller first loosen the wire tension

knob and move it into its down position (see fig.9-1) then move the tensioning roller assembly to its up

position (see fig.9-2). Take hold of the triangular knob on the roller retainer and rotate it 90°anti-clock

wise to release it as shown in fig.9.3. Now pull the roller retainer off the drive spindle to reveal the roller

as shown in fig.10. Pull the roller off the drive spindle, flip it over and put it back on the drive spindle.

(See fig 11) The groove size you require should now be visible on the face of the roller. Push the roller

retainer back onto the drive spindle with the opening facing left. Ensure that the flanges at the base of

the retainer, seat fully into the circular recess in the main moulding and then rotate the retainer through

90° to lock it in place.

7.4.

Contact tip

(to remove tip follow steps in 4.3).

The contact tip is a consumable item and must be

replaced when the bore becomes enlarged or oval. The contact tip MUST be kept free from spatter to

ensure an unimpeded flow of gas.

7.5.

Gas cup

(to remove cup follow steps in 4.3).

The gas cup must also be kept clean and free from

spatter. Build-up of spatter inside the gas cup can cause a short circuit at the contact tip which will

result in either the fuse blowing on the printed circuit card, or expensive machine repairs. To keep the

contact tip free from spatter, we recommend the use of an anti-spatter spray.

7.6.

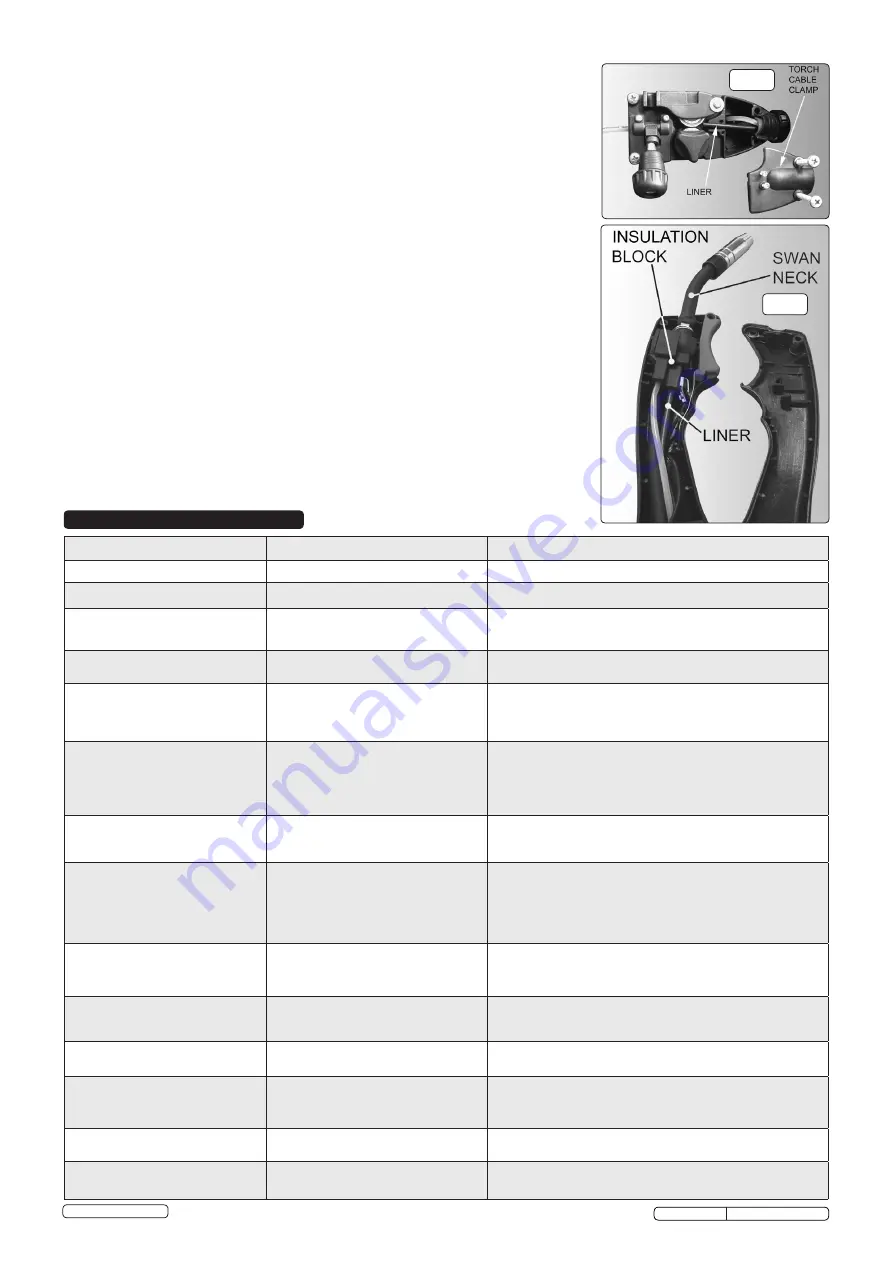

Replacing wire liner.

A worn or damaged wire liner will seriously affect the performance of the welder

and should be immediately replaced. First wind the wire back onto the spool and secure it. Remove the

four screws securing the torch cable clamp to the wire feed unit (fig.12) and take off the clamp. Undo

the torch case (fig.13) and pull the wire liner from insulation block. Pull out the liner from the torch

cable and insert the new one. Reverse the process to re-assemble. Ensure the liner is fully inserted

into the torch insulation block and reassemble the torch. Trim the other end of the liner as close to the

feed roller as possible. Replace the torch cable clamp.

7.7.

Replacing gears.

An inexperienced welder can allow spatter to build up in the tip and shroud. In severe

cases this can block the wire feed causing gear damage in the wire drive. To check if the gears are

worn depress the button on the torch with the set switched on. If the gears are worn, a grating sound

will be heard coming from the wire feed motor and you may also observe the feed roller vibrating

instead of rotating smoothly. In this case, open the gearbox, remove the worn or damaged gears and

replace with new ones.

fig.13

fig.12

PROBLEM

POSSIBLE CAUSE

REMEDY

Weld current interrupted

Overheating protection activated due to overload

Protection automatically resets when transformer has cooled (approx. 15 min).

No weld current, fuse blowing in 13amp plug

Rectifier blown

Replace rectifier.

No weld current

Bad connection between clamp and workpiece

Break in earth lead

Break in torch lead

Clean or grind contact surface and weld area.

Repair or replace earth lead.

Repair or replace.

Feed motor not working

Gear damaged or worn

Motor defective

Replace gears (Section 7).

Replace motor (Contact service agent).

Wire does not feed, feed roller rotates

Pressure roller improperly adjusted

Dirt, copper, dust, etc. have collected in torch liner

Gas cup (nozzle) or tip defective

Deformed wire

Adjust tension.

Clean the liner from the machine forward. Use compressed air. If too much dirt,

replace the liner (Section 7).

Replace gas cup (nozzle) and/or tip (Section 7). Check roller tension (Section 4).

Wire feeds unevenly

Dirt, etc, in liner

Gas cup (nozzle) or tip defective

Gas cup (nozzle) spattered

Feed roller groove clogged

Feed roller groove deformed

Pressure roller tension incorrect

Clean the liner from the machine forward using compressed air.

Replace gas cup (nozzle) and/or tip (Section 7).

Clean or replace gas cup (nozzle) (Section 7).

Clean feed roller (Section 7).

Replace feed roller (Section 7).

Adjust tension (Section 4).

Unstable arc

Incorrect settings

Impurities in weld area

Worn or defective gas cup (nozzle)

Check settings (Section 5).

Clean and/or grind workpiece (Section 5).

Replace gas cup (nozzle) (Section 7).

Porous weld

No gas

Gas cup clogged

Draft blowing away shielding gas

Rusty/dirty joints

Torch too far from, or at wrong angle to, workpiece

Gas leak

Open gas cylinder, regulate gas flow.

Clean or replace cup (Section 7).

Screen off welding site or increase gas flow.

Clean or grind the workpiece (Section 5).

Gas cup to workpiece should be 8-10mm. Torch angle approx 75º.

Check hoses, connections and torch assembly (Section 7).

Wire sticking in gas cup (nozzle)

Worn or defective gas cup (nozzle)

Wire deformed

Wire speed too slow

Replace gas cup (nozzle) (Section 7).

Check roller tension (Section 4).

Increase wire speed.

Irregulars weld bead

Torch incorrectly held

Wire weaving in weld pool

Use correct torch angle.

Check roller tension and adjust (Section 4).

Weld bead too narrow and raised

Weld current too low

Weld speed too fast

Increase power and wire speed (Section 5).

Move torch slower and weave a little more.

Weld bead too wide

Weld current too high

Weld speed too slow

Arc too long

Decrease current and wire speed (Section 5).

Move torch faster and weave less.

Bring torch closer to workpiece.

Poor penetration

Weld current too low

Arc too long

Increase current and wire speed (Section 5).

Bring torch closer to workpiece.

Excessive penetration

Weld current too high

Weld speed too slow

Incorrect distance of torch to workpiece

Decrease current and wire speed (Section 5).

Move torch faster.

Torch distance should be 8-10mm.

SUPERMIG130 Issue No:2(L) 26/08/14

Original Language Version

© Jack Sealey Limited

8. TROUBLESHOOTING