WARNING!

Before performing any maintenance operation, switch off the

compressor, disconnect from electricity supply and release all air from the tank

(except where a pressurised system is needed). In order to keep the compressor in

good working condition, periodical maintenance is essential.

6.1

Oil Replacement

6.1.1 remove the oil filler cap (fig.1a) and unscrew sight glass (fig.1B), draining the oil

into a container. Drain when the compressor is hot so that oil drains rapidly and

completely. Incline compressor to ensure complete drainage.

replace sight glass and refill. Do not overfill. replace filler cap (fig.1a).

6.1.2 recommended oil for compressors:

synthetic oil suitable for temperatures ranging from -5°c to 45°c, viscosity 5W50.

We do not recommend using mineral oil in these compressors.

Part No. Qty.

Description

fso1

1ltr x 12 compressor oil - fully synthetic

fso1s

1ltr x 1 compressor oil - fully synthetic

fso5

5ltr x 1

compressor oil - fully synthetic

WARNING! Never mix different oils and do not use non-detergent/low quality

oils as the compressor may be damaged.

Dispose of waste oil only in accordance with local authority requirements.

6.2

IMPORTANT WARNING

- air contaminants taken into the compressor will affect

optimum performance. Example: Body filler dust or paint overspray will clog the pump

intake filter and may cause internal damage to pump/motor components. Please note

that any parts damaged by any type of contamination will not be covered by warranty.

6. MAINTENANCE

Maintenance Procedure

Once a Week

Once a Month

Once a Year

check the oil level is in the middle of the sight glass. add more synthetic compressor

oil if needed.

4

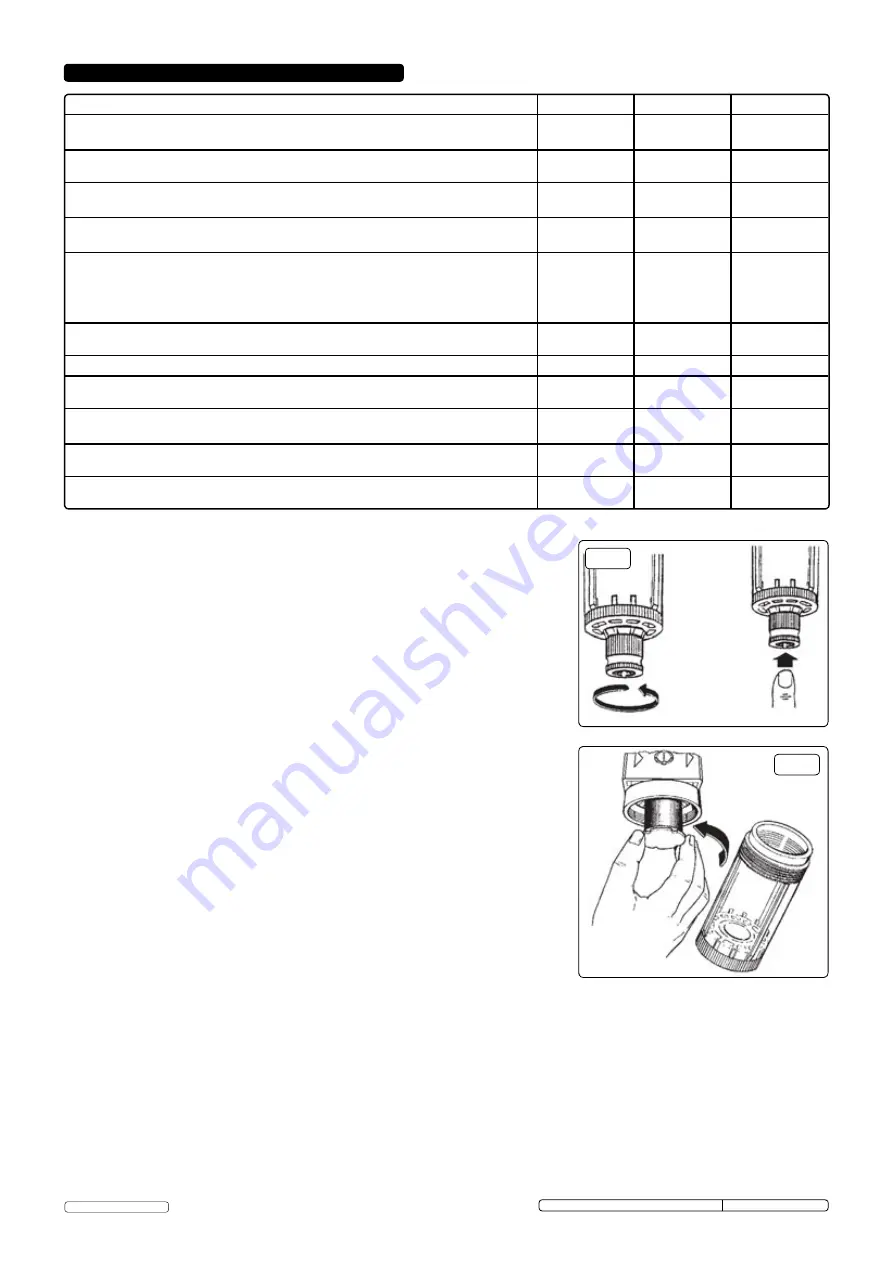

Drain the water collected in the air outlet filter. To be done under pressure (fig.6).

4

Drain the condensation that has collected in the air tank. Pressurise the tank, tip the

tank forward and open the drain tap.

4

Check all connections, pressure hose wear, all fixing are tight and all electrical

connections are secure and clean.

4

check the condition of the air filter (fig.1). If necessary remove the filter element and

clean by blowing through with an air line at low pressure, from the clean side or wash

in soapy water, rinse and dry. Do not operate the compressor without the filter as

foreign bodies or dust could seriously damage the pump.

Every 3 months

clean the compressor to prevent overheating.

4

Replace the cartridge in the outlet filter (fig.7).

Every 6 months

check the automatic cut-out at max. pressure and the automatic cut-in at 2 bar below.

4

Check the filter reducer and its parts to

optimise efficiency.

4

check the safety valve - pull the ring when the tank is pressurised.

4

replacement of oil. see instructions below.

4

fig.7

fig.6

Original Language Version

ssQc0903P, ssQc2405P, ssQc2409 Issue: 3 (sP) - 22/07/13

© Jack sealey limited