7.4.

OPERaTIONS TO BE CaRRIED OUT EVERY 200 HOURS:

a)

Replace the lubricating oil. For oil specifications see below. Remove the oil filler plug (fig.2A) and undo the drain bolt (fig.2C), draining

the oil into a container. Drain when the compressor is hot so that oil drains rapidly and completely. Incline compressor to ensure complete

drainage. Replace the drain bolt and refill with fresh oil through the filler aperture.

DO NOT

overfill. Replace plug (fig.2A).

Recommended oil for compressors, Suitable for room temperatures ranging from +5ºC to +25ºC. SEALEY CPO or equivalent SAE 40

compressor oil.

Room temperature below +5ºC: SAE 20 compressor oil.

WaRNING!

Never mix different oils and do not use non-detergent/low quality oils as the compressor may be damaged. Dispose

of waste oil only in accordance with local authority requirements.

b)

Check the automatic cut-out at max. pressure and the automatic cut-in at 2 bar below.

7.5.

OPERaTIONS TO BE CaRRIED OUT EVERY 500 HOURS:

a)

Replace air filter.

b)

Check all tube fittings and electrical connections.

IMPORTaNT! Failure to carry out maintenance tasks may invalidate the warranty on your compressor.

Inspection of pressure tank both inside and out.

7.6.

Under the

PRESSURE SYSTEMS SaFETY REGULaTIONS 2000,

it is the responsibility of the owner of the compressor to initiate a

system of inspection that both defines the frequency of the inspection and appoints a person who has specific responsibility for carrying

out the inspection.

IMPORTaNT WaRNING

- Air contaminants taken into the compressor will affect optimum performance. Example: Body filler dust or

paint overspray will clog the pump intake filter and may cause internal damage to pump/motor components. Please note that any parts

damaged by any type of contamination will not be covered by warranty.

8. TROUBLESHOOTING

FaULT

CaUSE

REMEDY

1A) Pressure drop in the tank

Air leaks at connections

Run compressor to max. pressure, switch off

Brush soap solution over connections and look for

bubbles. Tighten connections showing leaks

If problem persists contact Authorised Service Agent

1B) Pressure drop in the tank

Air leaks from safety valve

Operate the safety valve manually by pulling on the

ring. If valve continues to leak when in the closed

position it should be replaced

1C) Pressure drop in the tank

Air leaks from cylinder head gasket

Check tightness of head bolts. If leak continues

contact Authorised Service Agent

2) Pressure switch valve leaks when

compressor is idle

Non-return valve seal defective

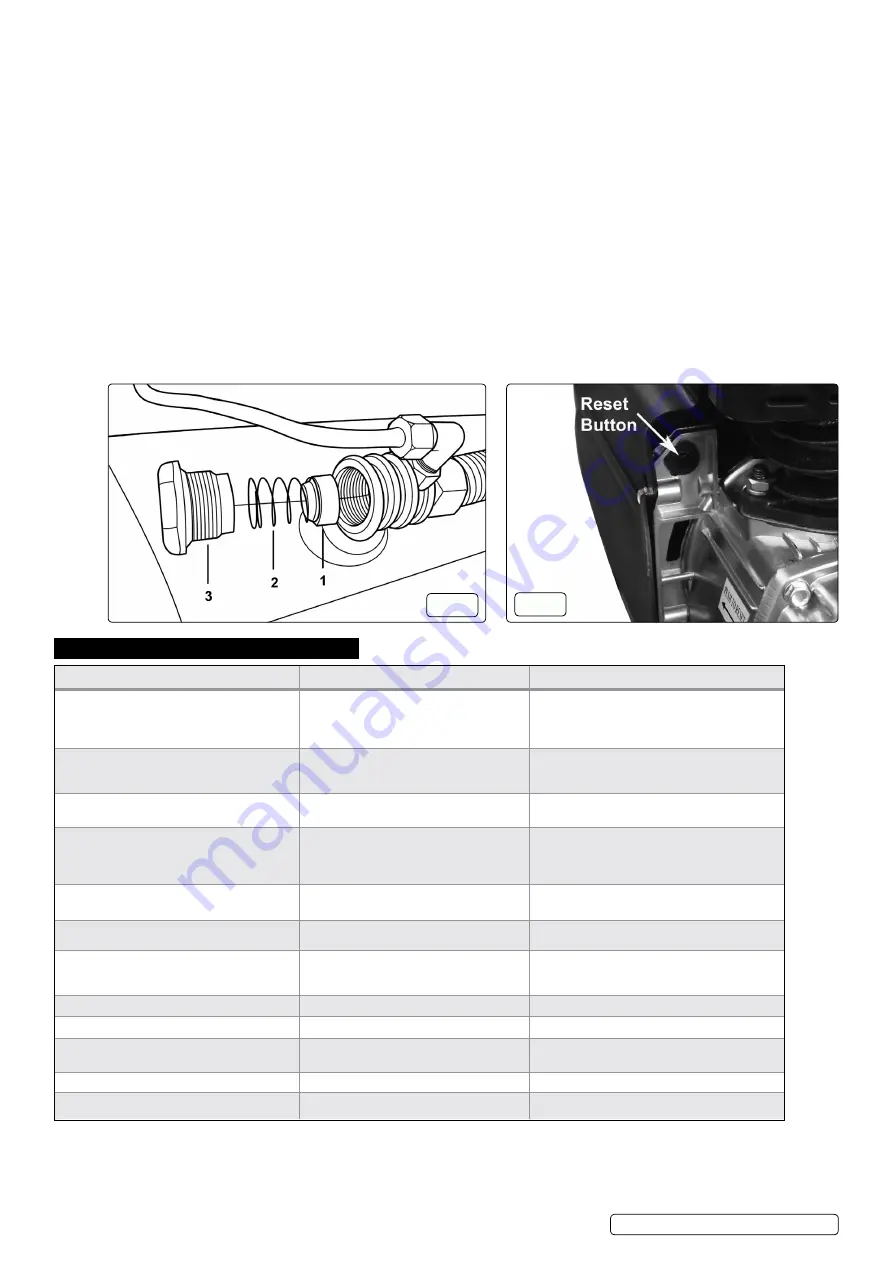

Empty the air tank. Referring to fig.6, remove the

non-return valve cap (3), spring (2) and seal (1)

Clean the seal and its seat, or if necessary replace

the seal

3) Air leaks from tank body or tank welds

Internal corrosion caused by infrequent tank

draining or non permitted modifications to tank

Tank could rupture or explode. Cannot be repaired

DISCONTINUE USE IMMEDIaTELY

4A) motor stops and will not restart

Thermal cut out has operated

Allow unit to cool for 30 minutes, then press reset

see fig.7.

4B) motor stops and will not restart

Supply fuse has tripped

Reset fuse and restart unit. If repeated tripping

occurs replace the check valve or contact

authorised service agent

5) Compressor stops and does not restart

motor failure

Contact Authorised Service Agent

6A) Compressor does not stop at max. pressure Pressure switch fault

Contact Authorised Service Agent

6B) Compressor does not stop at max. pressure Filter clogged

Head gasket or valve fault

Replace filter element.

Contact Authorised Service Agent

7) Compressor noisy with metallic knock

Bearing or piston damage

Contact Authorised Service Agent

8) Excessive moisture in discharged air

High humidity environment

Drain tank after each use

Original Language Version

© Jack Sealey Limited

SAC5020E110V.V3 | Issue:1 14/06/19

fig.6

fig.7