4.3.4.

DEPRESSED CENTRE OR FLAT GRINDING DISK

fig.5

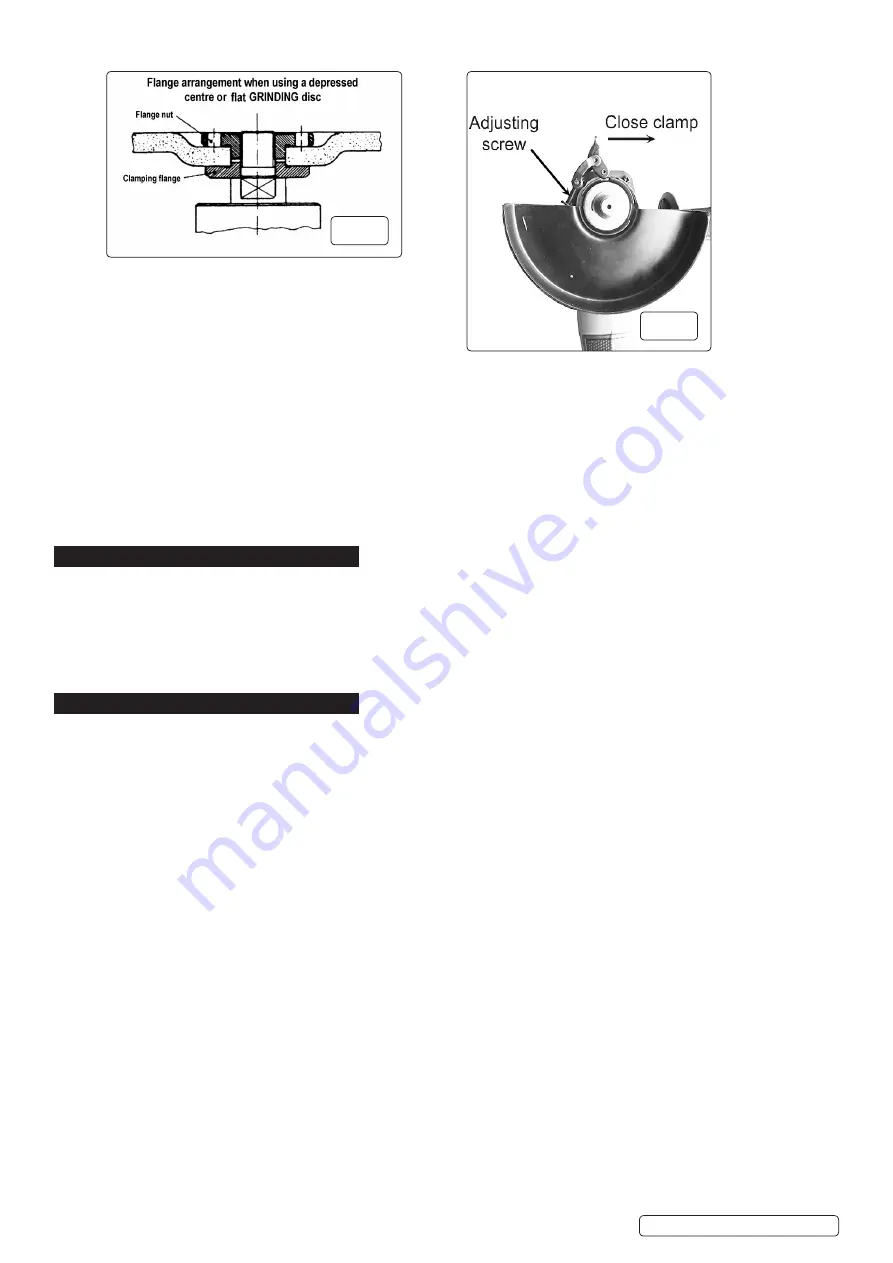

4.4.

GUARD ADJUSTMENT fig.6

WARNING:

Always work with guard in place.

WARNING:

Remove battery before fitting / removing wheels

or maintenance is carried out.

4.4.1.

Open clamp by raising lever and rotate to required location.

4.4.2.

Clamping force can be adjusted by screwing in the adjusting

screw.

4.5.

PREPARATION

4.5.1.

Attach grinding/cutting disc according to section 4.3 and position the handle grip conveniently for the task.

4.5.2.

Ensure the disc safety guard is correctly positioned.

WARNING!

When the grinder first starts it will kick to the right. You must ensure, therefore, that the tool is securely gripped in both hands.

Especially important is the position you choose for the side handle in order to maintain stability.

WARNING!

Before use, ensure that you are wearing approved safety goggles, ear defenders, appropriate dust mask if dust will

be generated and safety gloves, and that all other safety instructions in Section 1 are followed carefully.

4.6.

ON/OFF SWITCH fig.1

4.6.1.

The ON/OFF (I/O) switch (fig.1) is designed to avoid accidental starting. Slide it forward and then depress to lock in the ON position.

4.6.2.

To release the ON switch press it’s rear edge and it will return to the OFF position.

5. CONSUMABLES

WARNING! DO NOT

USE DISCS THAT ARE DAMAGED, OR SUSPECTED TO BE DAMAGED.

5.1.

Before using a grinding/cutting disc ensure that there are no fissures or cracks. Once mounted on the grinder, test the disc before use by

facing the grinder in a safe direction (point away from yourself, others and vulnerable items) and run for a short time.

▲

DANGER!

Use of damaged discs is dangerous and may cause personal injury.

5.2.

Grinding and cutting discs used in association with this machine shall be of an adequate speed rating and be suitable for the job in hand.

The discs shall be made in accordance with British Standard 4481:Part 1 1989. Only persons holding a grinding wheel certificate are

authorised to change grinding discs. Ensure that the speed rating on the disc is equal to, or higher than, that of the grinder.

6.

MAINTENANCE

WARNING:

Always disconnect the battery before carrying out any inspection, maintenance or cleaning.

6.1.

GENERAL INSPECTION

6.1.1.

Regularly check that all the fixing screws are tight.

6.1.2.

Repairs should be carried out by an authorised service centre.

6.2.

CLEANING

WARNING:

Always wear protective equipment including eye protection and gloves when cleaning this tool.

6.2.1.

Keep your tool clean at all times. Dirt and dust will cause internal parts to wear quickly, and shorten the device’s service life.

6.2.2.

Clean the body of your machine with a soft brush, or dry cloth.

6.2.3.

Never use caustic agents to clean plastic parts. If dry cleaning is not sufficient, a mild detergent on a damp cloth is recommended.

6.2.4.

Water must never come into contact with the tool. Ensure the tool is thoroughly dry before using it.

6.2.5.

If available, use clean, dry, compressed air to blow through the ventilation holes (where applicable).

6.3.

LUBRICATION

6.3.1.

Lightly lubricate all moving parts at regular intervals with a suitable spray lubricant.

6.4.

STORAGE

6.4.1.

Store this tool carefully in a secure, dry place out of the reach of children.

WARNING! – Risk of Hand Arm Vibration Injury.

This tool may cause Hand Arm Vibration Syndrome if its use is not managed adequately.

This tool is subject to the vibration testing section of the Machinery Directive 2006/42/EC.

This tool is to be operated in accordance with these instructions.

Measured vibration emission value (a): ..........5.598m/s²

Uncertainty value (k):.........1.5m/s²

Please note that the application of the tool to a sole specialist task may produce a different average vibration emission. We recommend that a

specific evaluation of the vibration emission is conducted prior to commencing with a specialist task.

A health and safety assessment by the user (or employer) will need to be carried out to determine the suitable duration of use for each tool.

NB:

Stated Vibration Emission values are type-test values and are intended to be typical.

Whilst in use, the actual value will vary considerably from and depend on many factors.

Such factors include; the operator, the task and the inserted tool or consumable.

Original Language Version

© Jack Sealey Limited

CP20VAGX Issue1 07/06/19

fig.5

fig.

6