PROGRAMMING THE TORQUE AND ANGLE.

The wrench has the ability to hold 5 torque and

angle settings in its memory

4.8

Target Torque Setting

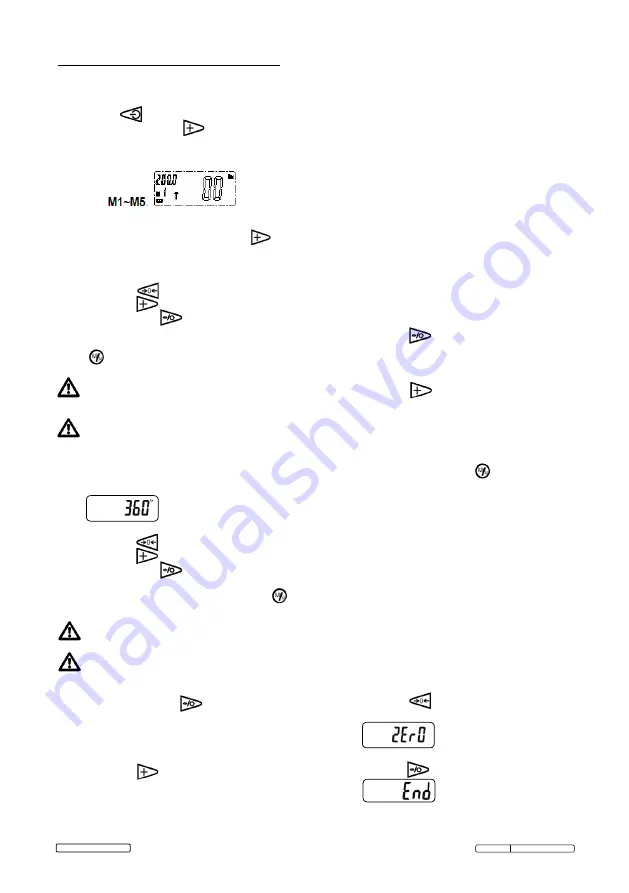

4.8.1 Press button to turn the wrench on.

4.8.2 Press and hold the button for 5

seconds (more if required) to select the

memory storage number between

M1 - M5

4.8.3 Once the memory number is chosen, access

the Target Torque by pressing the

button.

4.8.4 ‘ SET’ is shown on the screen.

4.8.5 The last saved torque will be shown.

4.8.6 Press the button to ZERO the figures.

4.8.7 Press the button to change each digit in

turn, press the button to move between

digits.

4.8.8 To confirm the torque figure is set, press the

button. Setting the angle will proceed.

If no buttons are pressed within 6 seconds

the display will continue to the angle

setting.

‘Erro’ will be shown on the screen if the

torque set does not fall between 10% and

100% of the range of the wrench.

4.9

Target Angle Setting.

4.9.1 When the torque setting has been confirmed

the wrench will go to angle setting.

4.9.2 The last saved angle will be shown.

4.9.3 Press the button to ZERO the figures.

4.9.4 Press the button to change each digit in

turn, press the button to move between

digits.

4.9.5 When the angle figure is set, press the

button to confirm.

If no buttons are pressed within 6 seconds

the display will return to the main screen.

‘Erro’ will be shown on the screen if the

angle set does not fall between 1° and

360°.

4.10 Display Back-light.

4.10.1 Press and hold the button for 5

seconds.

4.11 Torque Measurement.

4.11.1 Select the correct size socket and snap it onto

the wrench.

4.11.2 Press the button to scroll through the

pre-set torque figures (M1-M5).

4.11.3 Place the wrench onto a nut/bolt and begin to

tighten, use a smooth motion and avoid jerky

movements.

4.12 LED/Buzzer/Vibration Indicators-Torque.

4.12.1 When under 50% of the set torque, the LED

will flash GREEN.

4.12.2 After 50% of the torque figure has passed

the LED will change to a solid YELLOW.

4.12.3 When +/-5Nm from the set torque the buzzer

will sound.

4.12.4 The LED will change to RED when you are

within 2% of the set torque and handle

vibration will be felt.

4.12.5 When the set torque is reached the buzzer

will become quicker.

4.12.6 If you go over the set torque the wrench will

emit a continuous tone and the LED will turn

back to GREEN and handle vibration will be

felt.

4.13 Angle Measurement.

4.13.1 Press the button to switch to angle

measurement.

4.13.2 Select the correct size socket and snap it

onto the wrench.

4.13.3 Press the button to scroll through the

pre-set angle figures (M1-M5).

4.13.4 Place the wrench onto a nut/bolt and begin

to tighten, use a smooth motion and avoid

jerky movements.

4.13.5 To change the direction from clockwise to

anti-clockwise press the button. A minus

symbol will appear on the display.

4.14 LED/Buzzer/Vibration indicators - Angle.

4.14.1 When under 50% of the set angle, the LED

will flash GREEN.

4.14.2 After 50% of the angle figure has passed

the LED will change to a solid YELLOW.

4.14.3 The LED will change to RED when you are

within 2% of the set angle.

4.14.4 When the set angle is reached the buzzer

will emit a continuous tone and handle

vibration will be felt.

4.14.5 If you go over the set angle by 2% the LED

will turn back to GREEN and handle

vibration will be felt.

4.14.6 Press the button to ZERO the angle

for another reading. The below will display.

4.14.7 When all angle measurements are done,

press the button, the display will show

and switch to torque measurement mode.

Original Language Version

STW306B Issue:2(I) - 20/06/17

© Jack Sealey Limited