Rated on-load voltage

U

o

in

V

a) Peak value in case of direct current;

b) Peak & r.m.s. value in case of alternating current.

KVA

ED %

1

2

Rated weld current

U

2

Conventional load voltage

Mains supply and number of

phases (i.e. 1 or 3) with symbol

for alternating current.

PA

KVA

COS

U

1

... V/...Hz

Rated values of the supply voltage and the

frequency.

/

Rated supply current.

IP

Degree of protection, i.e. 21 or 23.

Welding power sources which are suitable

for supplying power to welding operations

carried out in an environment with increased

hazard of electric shock.

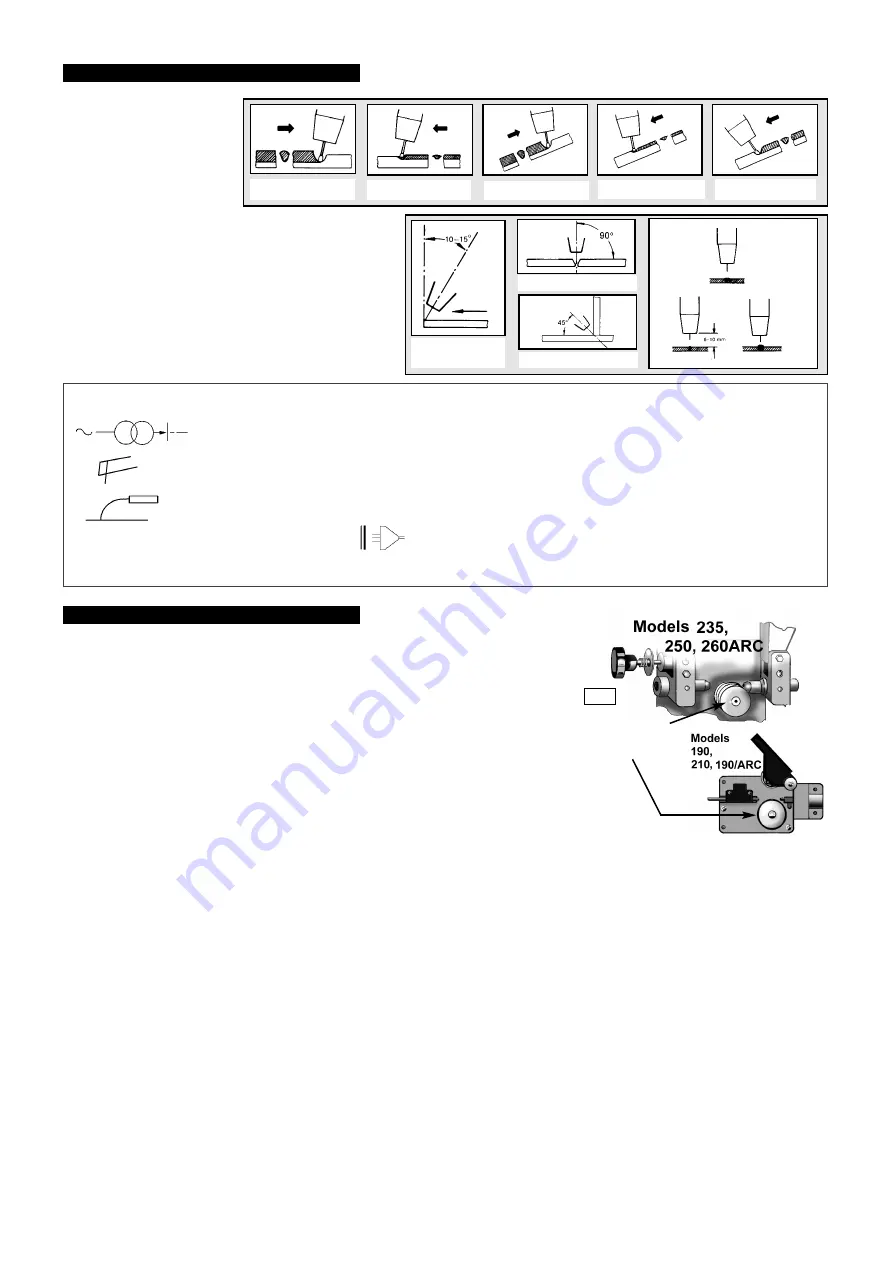

6. 1. Wire feed unit

Check the wire feed unit at regular intervals. The feed roller wire guide plays an important part

in obtaining consistent results. Poor wire feeding affects welding. Clean the rollers weekly,

especially the feed roller groove, removing all dust deposits.

6. 2. Torch

Protect the torch cable assembly from mechanical wear. Clean the liner from

the machine forwards by using compressed air. If the liner is clogged it must be replaced.

6. 3. Turning or Changing the Feed Roller

s

s

s

IMPORTANT:

Adjust the feed roller to the corresponding wire size.

There are two grooves on the feed roller, 0.6mm and 0.8mm. Always use the groove on the outside

of the roller, (the groove nearest to you). To remove the feed roller see fig 7.

Clean and turn, or if damaged change the feed roller.

6. 4. Contact Tip

(to remove tip follow steps in 3.3.6. and to replace 3.3.9. a & b very carefully).

The contact tip is a consumable item and must be replaced when the hole becomes enlarged or oval. The contact tip

MUST

be kept free from

spatter to ensure an unimpeded flow of gas.

6. 5. The Gas Cup (Conical Nozzle)

(to remove cup follow steps in 3.3.6. and to replace 3.3.9. a & b very carefully).

The gas cup must also be kept clean and free from spatter. Build up of spatter inside the gas cup can cause a short circuit at the contact tip

which will result in either the fuse blowing on the printed circuit card, or expensive machine repairs. To keep the contact tip free from spatter, we

recommend the use of Sealey anti-spatter spray (MIG/722307) available from your Sealey Dealer. We also recommend that you keep spare tips

and gas cups in stock.

6. 6. Replacing the Liner

Wind the wire back on to the spool and secure it. Remove torch from front panel by undoing knurled knob. Pull out torch and undo the brass nut.

Pull out liner and replace with a new one.

6. 7

Changing gears

An inexperienced welder can allow spatter to build up in the tip and shroud. In severe cases this can block the feed causing gear stripping in the

drive motor. To check if the gears are worn depress the button on the torch with the set switched on. If the gears are warn, a grating sound will

be heard coming from the wire feed motor, you may also observe the feed roller vibrating instead of rotating. Should this be the case, open the

gearbox, remove the worn or damaged gears and replace with new ones.

6. 8. Changing Fuses

The fuse is located on the front panel. Fuses are mainly blown for the following reasons:

3

Spatter collecting in the gas cup and contact tip causing a short circuit.

3

Wire tension is too great.

3

A sudden surge of current.

The position of the torch,

its angle and direction of travel

in relation to the workpiece

is essential for the appearance

and quality of the weld.

Illustrations demonstrate

various positions and

directions.

Rightward Welding

Welding in general

Welding with a long arc reduces penetration and widens

the arc.

This in turn results in more spatter.

A long welding arc can be appropriate for welding butt

joints in thin materials.

Welding with a short arc

(at the same weld settings

)

results in greater penetration and a narrower weld

and reduces the amount of spatter.

Leftward Welding

Vertical Rightward Downhard leftward

Down Rightward

5. VARIOUS WELDING METHODS

6. MAINTENANCE

fig 7

MEANINGS OF MARKINGS, AND SYMBOLS

Single-Phase

transformer

Flat Characteristic

MIG/MAG welding

...A/ ... V to ...A/ ... V

Range of output, rated min

& max welding current and

their corresponding

conventional load voltage.

1. Direction of

Welding

3. Fillet Weld

3. Butt Weld

Normal

Welding

Arc

Short

Welding

Arc

Long

Welding

Arc

To remove roller

locate and undo the

hex nut on the side

of the roller

AUTOMIGS 190,210,235,250, 190ARC & 260ARC - (0095) - (1) - 010299