www.seagullmodels.com

3

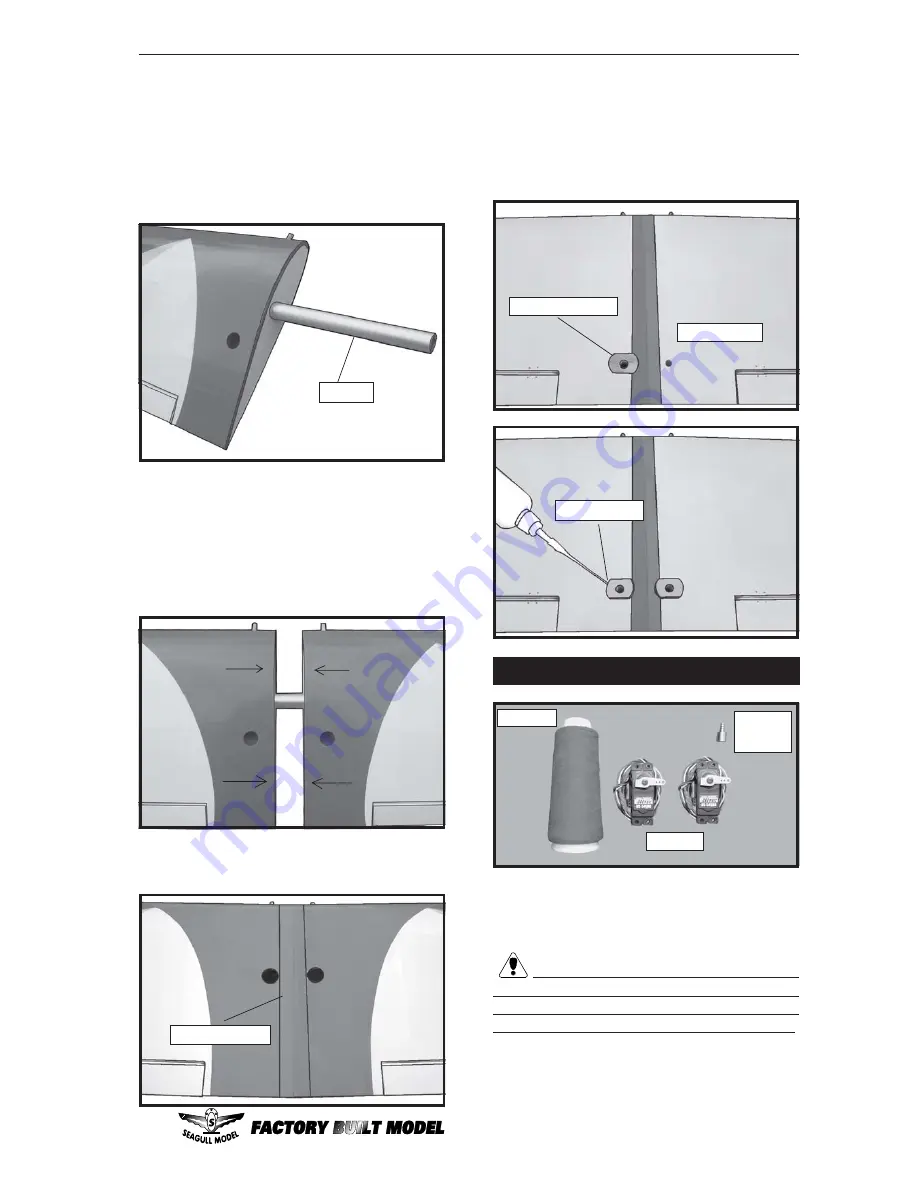

3) Peel off the backing from the self adhe-

sive covering strip. Apply the strip to the centre

section of the wing starting from the bottom

trailing edge. Wrap the strip all the way around

the wing until it meets the trailing edge again.

Trim off any excess strip.

Carefully slide the two wing halves together

and firmly press them together, allowing the

excess epoxy to run out. There should not be

any gap in the wing halves. Use rubbing

alcohol and a paper tower to clean up any

excess epoxy.

Apply masking tape at the wing join to hold

the wing halves together securely.

2) Remove the brace when satisfied with

its fit ineach wing half. Coat both sides of one

half of the dihedral brace with 30 minute epoxy.

Next, pour some epoxy into the dihedral box in

one wing panel. Make sure you cover the top

and bottom as well as the sides of the dihedral

brace. Use enough epoxy to fill any gaps.

Glue attach.

Masking tape.

Remove covering.

Wing botton.

Epoxy.

INSTALLING THE AILERON SERVOS.

Because the size of servos differ, you

may need to adjust the size of the precut open-

ing in the mount. The notch in the sides of the

mount allow the servo lead to pass through.

1) Install the rubber grommets and brass

collets onto the aileron servo. Test fit the

servo into the aileron servo mount.

2) Using a small weight (

Weighted fuel pick-

up works well

) and thread, feed the string

through the wing as indicated.

Small

weight.

Servos.

Thread.