Page 23

Page 23

consequently to the compressor and fan motors

and 30" later, to the water pump motors.

Then, as the ice thickness reaches the value that

corresponds to the full cube size, the film of water

that constantly cascades over the slab of ice

formed on the evaporator, arrives to establish a

contact between the two fingers (energised at

low voltage) of the ice sensor control, located on

the front upper right side of the evaporator. If the

contact between the two fingers of the ice sensor

remains established - by the film of water - for

more than 10 seconds, a small relay of the

electronic board, get energized, controlling -

simultaneously the hot gas valve, the water drain

valve and the harvest assist solenoid.

NOTE: in case of failure of ice level sensor,

the P.C. Board turns - on automatically the

unit into the defrost cycle when the freezing

cycle reaches 30 or 40 minutes according to

the operation of the fan motor during the

freezing cycle.

At this point, the unit initiates the defrost cycle.

The hot gas circulating into the evaporator

serpentine causes a slight melting of ice cubes

which get released from their molds. In the mean

time the harvest assist solenoid is also energized

pushing out the ice plate.

Once entirely released the ice cubes drop

simultaneously into the ice storage bin below; by

doing so they move apart from the evaporator

bottom end the plastic deflector.

This plastic deflector has on its side a magnetic

switch that on account of the deflector swinging

motion, caused by the ice while dropping in the

bin, opens and closes their contacts.

This will, in turn, disactivate the relay contacts

that controls the hot gas, harvest assist solenoid

and water drain valve which get deenergized

allowing the unit to start a new freezing cycle.

When the ice bin is full of ice, the last batch of ice

cubes released from the evaporator accumulates

to keep the bottom end of the plastic deflector in

open position; with the magnetic switch contacts

open for longer than 30'’ the entire unit stops with

the glowing of the corresponding LED.

The machine will restart when the ice deflector will

be back in its normal vertical position provided

that 3' are elapsed from unit stop. If not the

machine will delay its restart till 3' are elapsed with

the blinking of the green LED.

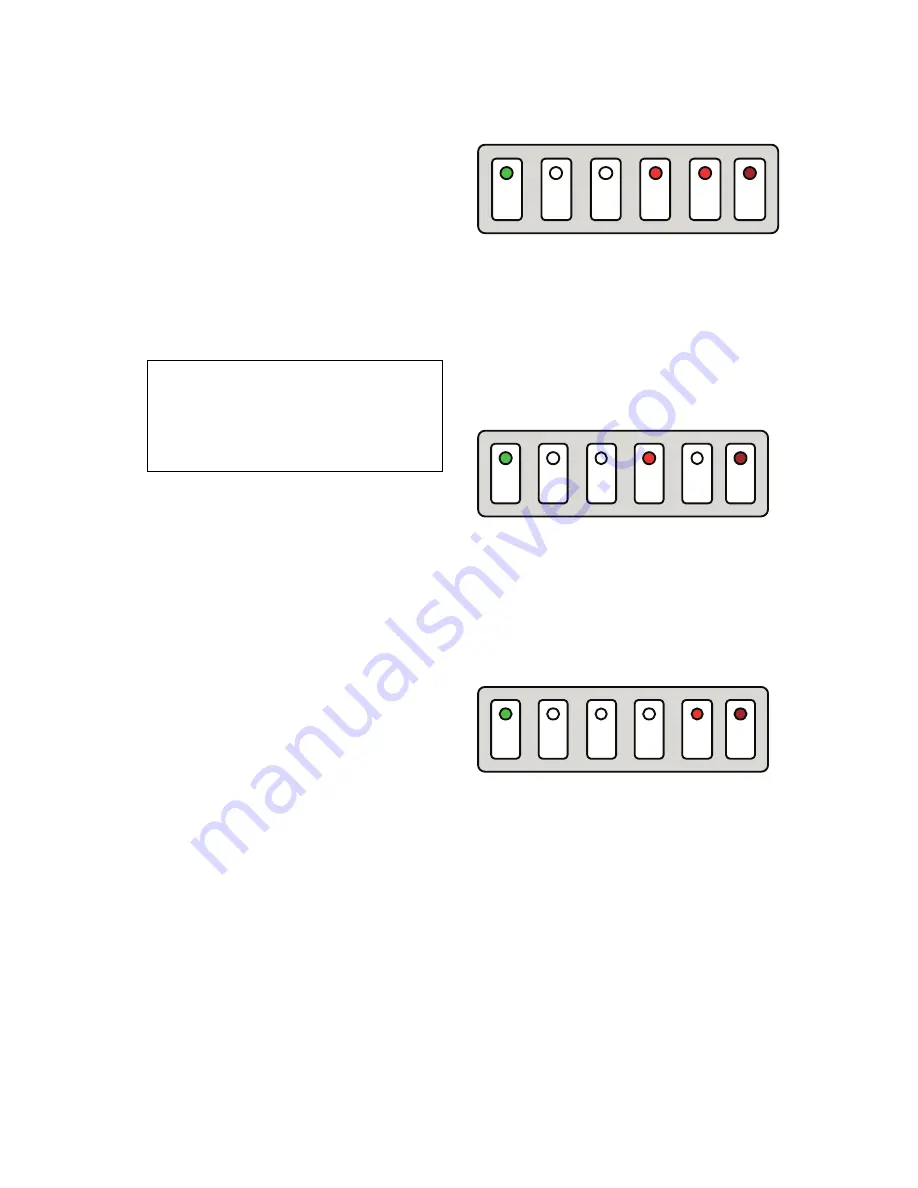

ALARM CONDITIONS

Both the last two Red LED are ON STEADY:

Condenser Sensor OUT OF ORDER.

Both the last two Red LED are BLINKING SLOW:

WATER ERROR

Water level inside the water sump too low after 3'

from the activation of the Water Inlet Valve.

Both the last two Red LED are BLINKING FAST:

RESET MODE: Charging water through the Water

inlet Solenoid Valve after the tripping OFF on

WATER ERROR

The fourth Red LED is ON STEADY: Harvest

Cycle longer then 3' 30"

The fourth Red LED is BLINKING SLOW: TOO HI

CONDENSING TEMPERATURE. The condenser

sensor detected a temperature > 65

°

C

The fourth Red LED is BLINKING FAST:

RESET MODE: Condenser Sensor < 50

°

C Fan

motor in operation for 3' then back on Start Up

Cycle Mode

The fifth Red LED is ON STEADY: TOO HI

DISCHARGE PRESSURE > 33 bar (460 PSI)

The fifth Red LED is BLINKING FAST:

RESET MODE: After pushing the Reset

Button of the Pressure Control the fan motor

starts up first for 3' then the machine enters

on the Start Up Cycle Mode.

The PC Board is also checking the maximum

time of the freezing cycle that changes according

to the operation of the fan motor during the

freezing cycle (room temperature):

• Fan motor in

Max. freezing cycle length

ON-OFF mode:

equal to 30'

• Fan motor ON

Max. freezing cycle length

All the time:

equal to 40'

Whenever the machine remains in the Freezing

Cycle for the Maximum time (30 or 40 minutes),

the PC Board moves the unit directly into the

Harvest Cycle.

POWER

OPER.

BIN

FULL

ALARM

ALARM

HI

PRESS.

RE-SET

POWER

OPER.

BIN

FULL

ALARM

ALARM

HI

PRESS.

RE-SET

POWER

OPER.

BIN

FULL

ALARM

ALARM

HI

PRESS.

RE-SET