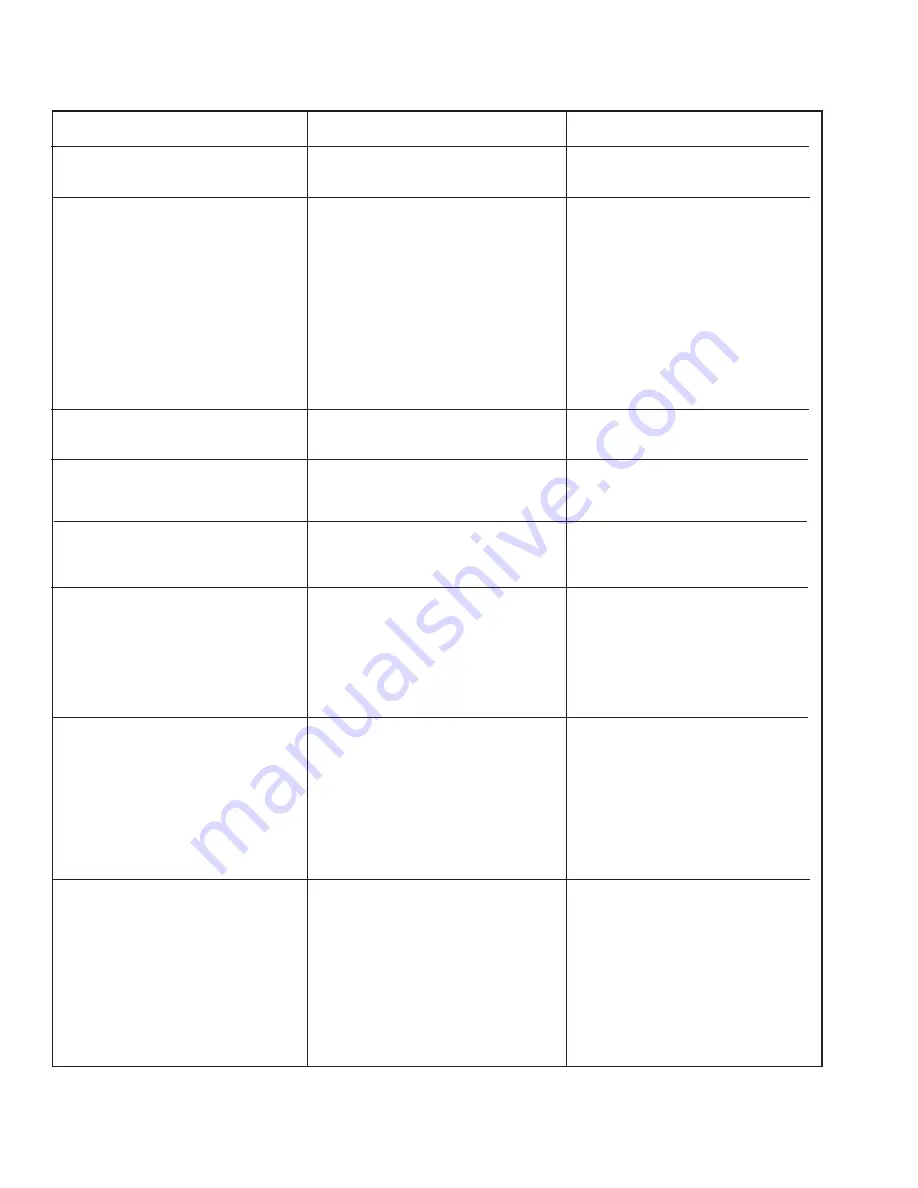

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

1. Compressor will not operate.

1. No electrical power.

1. Turn on power.

2. Pressure switch not making contact

2. See pressure switch adjustment.

2. Excessive noise in operation

1. Loose pulley, flywheel, belt, beltguard, 1. Tighten.

cooler, clamps or accessories.

2. Lack of oil in crankcase.

2. Check for possible damage to

bearings, replenish oil.

3. Piston hitting the valve plate.

3. Remove the compressor cylinder

head and inspect for foreign

matter on top of the piston.

Add a new gasket and reassemble

the head.

4. Compressor floor mounting loose.

4. Tighten.

5. Defective crankcase.

5. Repair or replace.

6. Excessive crankshaft end play.

6. Adjust and shim properly.

3. Knock - same cycle as R.P.M.

1. Main bearings.

1. Replace bearings.

2. Connecting rod bearing.

2. TIghten.

4. Knock occurs while

1. Connecting rod bearings.

1. Replace rod.

compressor is loading.

2. Wrist pins, wrist pin bearings.

2. Replace complete piston

assembly.

5. Milky oil in oil reservoir.

1. Water entering oil reservoir due

1. Pipe air intake to less humid air\

to compressor operating in high

source.

humidity environment.

6. Excessive oil consumption.

1. Restricted air intake.

1. Clean or replace air filter.

2. Oil leaks.

2. Tighten bolts or replace gasket.

3. Worn piston rings.

3. Replace piston rings.

4. Wrong oil viscosity.

4. Drain oil, refill with oil or proper

viscosity. See Lubrication Section.

5. Compressor titled too much.

5. Level compressor.

6. Scored cylinder.

6. Replace cylinder.

7. Oil in discharge air.

1. Compressor air intake restricted.

1. Clean air filter element and check

for other restrictions in the intake

system.

2. Worn piston rings.

2. Replace rings.

3. Excessive oil in compressor.

3. Drain down to full mark on sight

gauge.

4. Wrong oil viscosity.

4. Check viscosity.

See Lubrication

Section.

5. Piston rings installed up-side down.

5. Install ring in proper position.

8. Compressor vibrates.

1. Mounting bolts loose.

1. Tighten.

2. Compressor not properly mounted.

2. Level compressor so that all feet

touch the floor before tightening

down.

3. Pulley and flywheel misaligned.

3. Realign.

4. Belts loose.

4. Tighten belts. See Maintenance

Section.

5. Bent crankshaft.

5. Replace crankshaft.

6

Содержание SA315240H346

Страница 8: ...823015 Two Stage Compressor Pump 8...

Страница 10: ...10...