4

Operating instructions

Hinge safety switch

TESK

EN

The minimum bending radius must be observed for versions

with a cable connection!

Please note the load information "Determining the

permissible forces as a function of door size and number

of hinges" (see Section 7.3 Load details)

The hinge safety switch must not be used as an end stop.

For applications in which heavy doors are used and for use

on hoods, especially if these can close with little or no braking

effect, further measures are to be implemented to prevent the

securing bolts from working loose. A reduction in the service

life is also expected. The use of hydraulic struts on hoods

is not permitted as otherwise the hinge switch would be

damaged beyond repair.

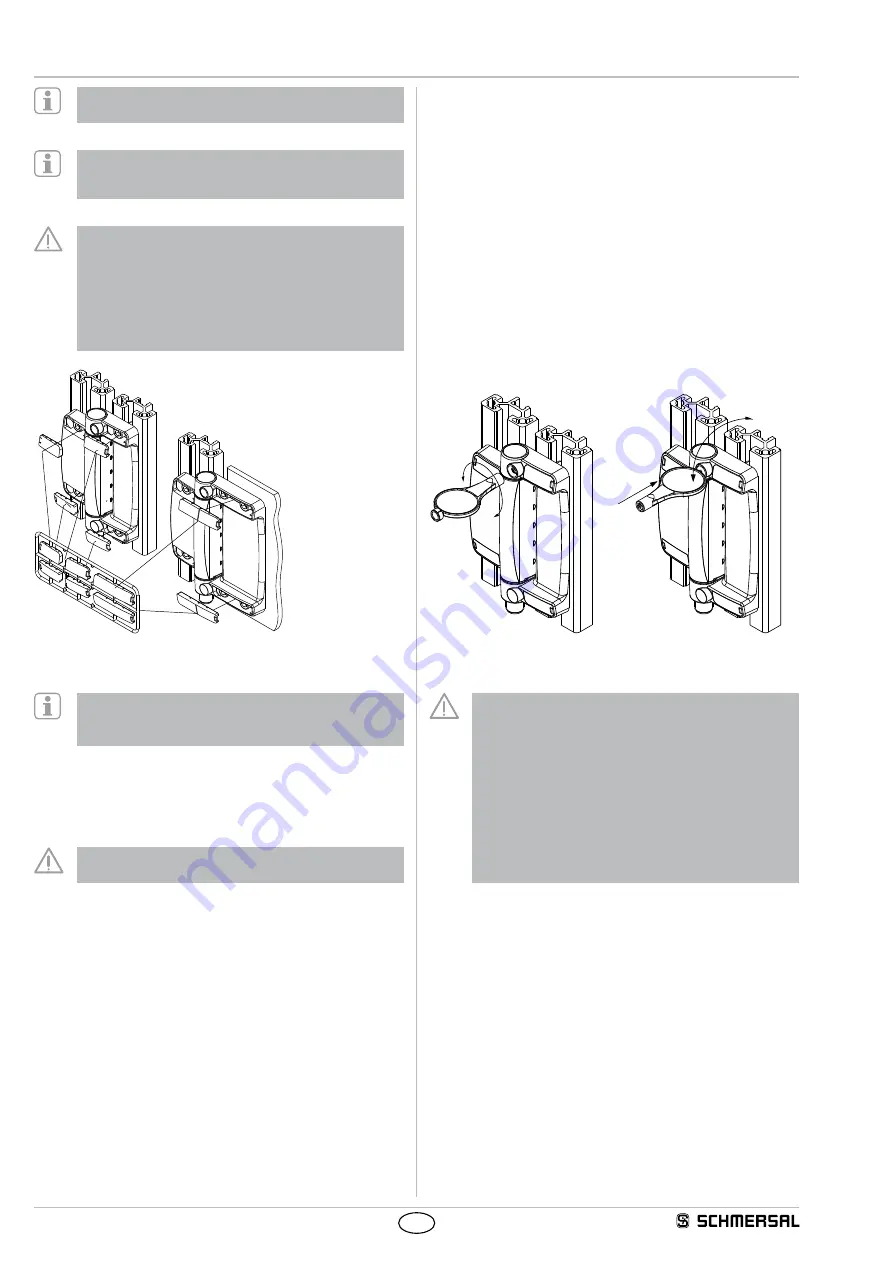

Fig. 4

Please observe the relevant requirements of the standards

ISO 12100, ISO 14119 and ISO 14120. Also observe the

safety distances to the standards ISO 13857 and EN 349.

3.2 Adjustment and inspection of the switching angle

After the switch has been fitted, the switching function and the opening

angle of the safety guard must be checked. The switching angle of the

NC contacts set in factory is approximately 3°.

Caution: for the TESK...-U version, the following paragraph

"Special instructions for the on-site setting" must be observed!

Special instructions for the on-site setting (version TESK...-U)

We recommend a setting including the following steps:

1. Open guard system up to maximum permissible door gap

(see table chapter 7.2 Determining door gap).

2. Use the adjustment tool to set the normally-closed contacts in such

a way that they are securely opened with the maximum permissible

door gap. Turning clockwise results in a smaller switch angle while

turning anticlockwise results in a larger switch angle (fig. 6); this is

the opposite when mounted inside. To decrease the switching angle,

turn counterclockwise to increase the switching angle (Fig. 6); when

mounted inside accordingly reversed.The positive break angle is 7°

larger than the set switching angle.

3. After the switch is set, the compliance of the switch with the

safety-technical requirements of the application must be checked

(see Section 7.2 Door gap calculation).

4. After the switching angle has been set and checked, the blanking

plug for the adjustment opening located at the rear of the adjustment

tool must be inserted in the adjustment opening (1) and torn down

by making lateral movements (2) with the tool (Fig. 7).

-

+

1

2

Fig. 6

Fig. 7

After the desired switching point is set, the opening of the set-

ting option imperatively must be sealed with a blanking plug.

This measure prevents tampering at the set switching point

within the meaning of ISO 14119 paragraph 5.7 and therefore

avoids any loss of the safety function of the device.

The blanking plug is injected to the special adjustment tool

with a predetermined breaking point.

We recommend an additional painting or glueing of the

blanking plug.

Securing the setting screw by means of the blanking plug is a

mandatory instruction for the user, which must be oberved in

order to maintain the CE-Conformity of the component.