8

Operating instructions

Safety light grids

SLG440

EN

3.4 Setting mode

Setting tool with 7-segment display

The function supports the best possible alignment between transmitter

and receiver The indication shows the signal strength of the different

receivers while the safety outputs are switched off lt setting) as well as

the best possible orientation of all beams (find adjustment)

Activating setting mode

After the system start, a signal impulse (H signal 24 VDC) must be

present at the input restart interlock (pin 1) of the receiver for at least

20 seconds (pushbutton/enabling)

The 7 segment display starts with the default setting (vertical bar)

The sensors are aligned in parallel and at the same height until both

segments have reached a signal strength of 50% to 100%

With a signal impulse on the input release (pin 1) you can change be-

tween default setting and fine adjustment as long as the signal strength

is at 50% of the default setting (vertical bar)

After the setting of the sensors, the setting mode can be terminated

by the presence of a HI-signal at pin 1 for at least 25 seconds (max

6 seconds) and the actuation of the enabling button or by a voltage

reset at the receiver (+UB).

Status display

The signal strength is also shown on the display in the diagnostic win-

dow by yellow light pulses to the status light The better the alignment,

the higher the frequency of the light pulses The alignment is correct

when the light pulses switch over to continuous light

If there is no optical synchronisation between the transmitter and the

receiver, a light pulse is emitted every three seconds The setting mode

is ended by a system start ( +UB OFF/ON).

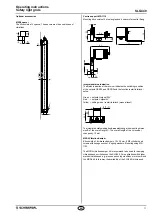

Alignment

Receiver not parallel

Both sensors parallel

b

a

b

a

Beam (a) = receive signal OK

Beam (b) = no receive signal

Beam (a) and beam (b)

= receive signals OK

Indication basic setting

The signal strength is displayed per beam with two segments for the

first (a) and the last (b) beam

Status first beam (a)

Status last beam (b)

2 segments left-hand side = signal strength of the

first

beam (a)

2 segments right-hand side = signal strength of the

last

beam (b)

Signal strength (a) 25% … 50%

Signal strength (b) 0%

Signal strength (a) 50% … 100%

Signal strength (b) 0%

Signal strength (a) 50% … 100%

Signal strength (a) 25% … 50%

Signal strength (a) 50% … 100%

Signal strength (a) 50% … 100%

Inadequate alignment of the sensors

(height offset, not parallel)

Indication fine adjustment

The fine adjustment is displayed by means of up to 3 segments

(crossbars) for the best possible signal strength of all beams

Best possible signal strength

Signal strength for normal operation OK

- Signal strength is sufficient, if one or more beams in the

protection zone are covered (object blanking)

- Signal strength insufficient, when no beams are covered

The availability of the system is also assured if due to soiling

or operation at nominal range the best possible signal

strength (3 segments)is not reached

3.5 Safety distance

The safety distance is the minimum distance between the SLG440 and

the hazardous point, which must be observed in order to ensure that

the hazardous point can only be reached after the hazardous

movement has come to standstill

The protection using individual beams must be chosen so

that bodies or body parts larger than the selected resolution

(beam di beam diameter 10 mm) of the SLG440 are

detected

Calculation of the safety distance to EN ISO 13855 & EN ISO 13857

The safety distance depends on the following elements:

• Stopping time of the machine (calculation by run-on time measure

-

ment)

• Response time of the machine and the safety light grid and the down

-

stream relay (entire safety guard)

• Approach speed

• Resolution of the safety light grid