2

Operating instructions

Safety sensor

BZ 16

EN

1.6 Warning about misuse

In case of inadequate or improper use or manipulations of the

safety switchgear, personal hazards or damages to machi

-

nery or plant components cannot be excluded. The relevant

requirements of the standard EN 1088 must be observed.

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages resul-

ting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary re

-

pairs, conversions and modifications to the device are strictly forbidden;

the manufacturer shall accept no liability for damages resulting from

such invasive work, arbitrary repairs, conversions and/or modifications

to the device.

2 Product description

2.1 Ordering code

This operating instructions manual applies to the following types:

BZ 16-

➀ ➁

No.

Option

Description

➀

11

1 NO contact / 1 NC contact

02

2 NC contacts

➁

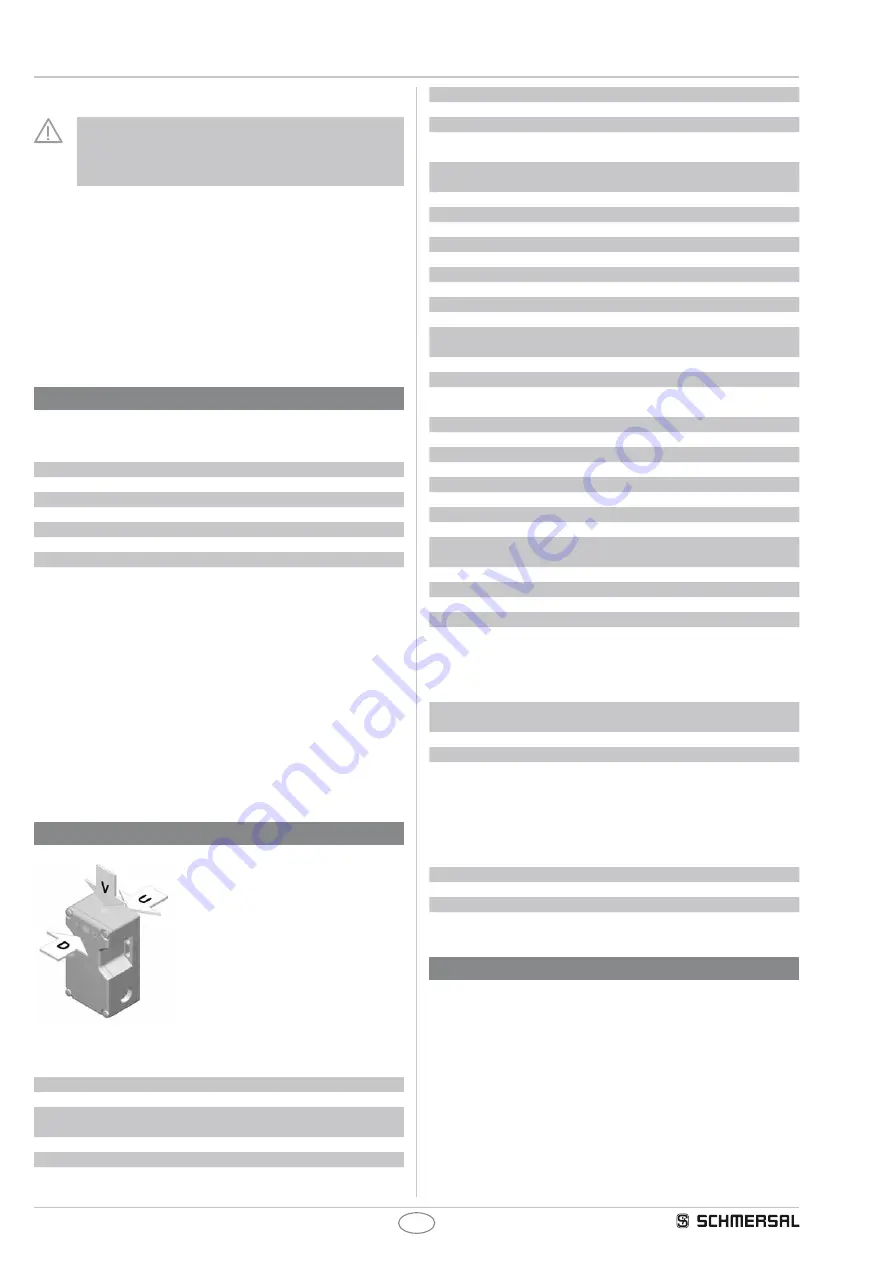

Actuating planes:

D

cover-side

U

bottom

V

front side

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Destination and use

The safety sensor is designed for application in safety circuits and is

used for monitoring the position of movable safety guards to EN 1088

and IEC 60947-5-3. To actuate the safety sensors, only the BZ 16-B1

actuator can be used, conventional magnets are not suitable.

The safety switches are used for applications, in which the hazardous

situation is terminated without delay when the safety guard is opened.

Actuating planes

2.4 Technical data

Standards:

IEC 60947-5-3, BG-GS-ET-14

Design:

rectangular

Enclosure:

glass-fibre reinforced thermoplastic,

self-extinguishing

Protection class:

IP 67 to EN 60529

Termination:

Screw terminals

Cable section:

max. 2 x 1.5 mm

2

(including conductor ferrules)

Cable entry:

3 x M20

Operating principle:

non-contact, with coded actuator

Actuating magnet:

BZ 16-B1, coded

s

ao

:

10 mm minimum distance 2 mm in case

of approach from side

s

ar

:

20 mm (minimum distance 2 mm in case

of approach from side)

Hysteresis:

approx. 6 mm

Repeat accuracy R:

< 1 mm

I

e

/U

e

:

160 mA / 24 VDC ±15 % (polarity reversal)

No-load current:

≤ 70 mA

Max. fuse rating:

0.25 A (slow blow)

Outputs:

2 enabling paths 2 NC or 1 NC / 1 NO

Switching voltage:

max. 250 VAC

Switching current:

max. 4 A

Switching capacity:

max. 1000 W

Required short-circuit

current:

100 A

Voltage drop:

see Contact resistance

Max. fuse rating:

4 A gG D-fuse

Utilisation category:

AC-15: 230 V / 3 A

DC-13: 24 V / 4 A

Power consumption:

< 4 W

U

i

:

250 VAC

Overvoltage category:

III

Degree of pollution:

3

U

imp

:

4 kV

Max. switching frequency:

1 Hz

Duration of risk:

< 200 ms

Ambient temperature:

0 °C … + 55 °C

Storage and transport

temperature:

- 20 ºC … + 70 °C

Resistance to shock:

30 g / 11 ms

Resistance to vibrations:

10...55 Hz, amplitude 1 mm

Mechanical life:

50 million operations

Contacts:

AgSnO, self-cleaning, positive drive

Contact resistance:

100 mΩ in new state

2.5

Safety classification

Standards:

EN ISO 13849-1, EN 62061,

IEC 60947-5-3

PL:

up to e

Control category:

up to 4

PFH value:

4.73 x 10

-8 /

h

Applicable for applications with up to max.

100,000 switching cycles/year (NC/NC

version) or 50,000 switching cycles/year

(NO/NC version) and with max. 250 mA

contact load. Diverging applications upon

request.

SIL:

up to 3

Service life:

20 years

Classification:

PDF-M

3 Mounting

3.1 General mounting instructions

•

Fitting is only authorised in a de-energised condition

•

Do not use the sensor and the actuator as a mechanical backstop

• Any mounting position, provided that the active surfaces are opposite

• Inseparably fix the safety sensor and the actuator to the safety guard

(the mounting dimensions are indicated on the back of the enclosure)

• Fix the safety sensor and the actuator onto a flat surface

• Do not install the sensor and the actuator in strong magnetic fields

• If possible, do not mount the sensor and the actuator on ferromagne

-

tic material

•

Do not subject the components to extreme vibrations

•

Keep away from metal chips

•

Mounting distance between two sensors should always be at least

10 mm