Operating Manual 90° ACTUSAFE CMF(S)QT

OM-ENGLISH-Failsafe-QT-16xx-V2.00-2022.03.01

16 Training

Viscosity class:

68 ISO VG

Pourpoint:

< -54°C (according DIN ISO 3016)

Lubricant requirement CM03:

200. . . 250 ml

Lubricant requirement CM06:

300. . . 350 ml

Lubricant requirement CM12:

600. . . 650 ml

15.3

Output type A and spindle drives (linear actuators) -40 to +60°C

Grease DIN 51825-K(P) R -40

i.e. water repellent complex grease on Al-soap base with high resistance to acids and alkalis

Penetration 0.1 mm:

310 -340

Dropping point:

about 260°C

NLGI No.:

1

acid-free, little or not water-reactive

15.4

Basic lubricant service interval

NOTE:

Schiebel actuators must be serviced 10 years after delivery by SCHIEBEL Antriebstechnik GmbH, A-1230 Vienna.

The functionality and durability of the lubricant is however contingent upon the operating conditions. Where applicable,

reduction factors must be considered.

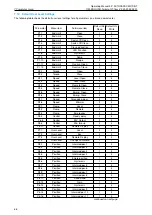

Operating condition (s)

Definition

Reduction factor

(multiplier)

Duty time DT

(Total engine running time)

Extremely high DT

over 1250 hours/year

0.5

High DT

over 500 hours/year

0.7

Extremely low DT

less than 0.5 hours/year

0.8

Ambient temperature

(permanent or long-term)

Extremely changeable

between -10 and +50°C

0.5

Extremely high

above +50°C

0.7

Extremely low

below -25°C

0.9

Output speed

(on actuator main shaft)

High speed

over 80 rpm

0.8

Utilisation

(relative to rated power)

Very high

over 90%

0.8

High

between 80 and 90%

0.9

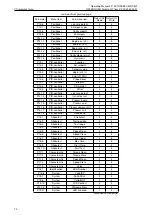

Application example:

Extremely low DT + extremely low ambient tempe high speed + 87% utilization

⇒

0.8 * 0.9 * 0.8 * 0.9 = 0.51 reduction factor

Lubrication maintenance interval

⇒

10 years * 0.51 = 5.1 years (62 months).

CAUTION:

This calculated maintenance interval does neither apply to the maintenance of output type A

(threated bushing) units nor to the maintenance of linear and spindle drive units. These units must be peri-

odically lubricated (at least every 6 months) via the grease nipples (see section 15.3)!

During maintenance of our actuators, remove and replace old grease with new one.

Mixing of different lubricant types

is NOT permitted.

Quantities needed for lubricant service are listed in section 15, page 76.

16

Training

NOTE:

If you experience problems during installation or upon adjustments on site, please contact SCHIEBEL, Vienna

at +43 (1) 66 108 or via the Internet at www.schiebel-actuators.com to prevent any operational errors or damage to the

actuators. Schiebel recommends engaging only qualified personnel for installation of Schiebel actuators. Upon special

request of the client, SCHIEBEL can conduct training on the activities listed in this operating manual at the factory of

SCHIEBEL.

79

Содержание CM03

Страница 1: ...Operating Manual 90 ACTUSAFE CMF S QT OM ENGLISH Failsafe QT 16xx V2 00 2022 03 01 ...

Страница 97: ...CM03 FSQT ...

Страница 98: ...CM06 FSQT ...