5

causes, if the limits are exceeded. Refer to

ISO 14694.

For variable speed fans the maximum

vibration level is likely to be exceeded at

certain speeds. Continuous operation at

these speeds must be avoided. A curve

showing vibration levels at different

speeds is part of the fan documentation

for variable speed fans and should be

reviewed by the user.

Notice:

The vibration levels depend on

the installation and should be

measured after completing the

installation.

6.4 Fan casing

The fan casing requires no maintenance

other than ordinary cleaning.

If the casing is painted, the surface

should be checked regularly and

repaired where necessary.

6.5 Rotor

The rotor is manufactured with the

blades mounted to the pitch

corresponding to the desired operating

point based on pressure, airflow and fan

speed. To ensure vibration free operation

the rotor has been carefully balanced.

Vibrations occurring during operation

may be due to accumulation of dust and

dirt on the hub and blades. These

disappear after cleaning. If vibrations

persist, expert assistance should be

called for immediately. Continued

vibrations shorten the life of the motor

bearings.

6.6 Motor

Refer to the motor manual for service

information such as the number of

running hours before inspection and

replacement of bearings.

It is recommended to check the motor

bearings after 20,000 running hours and

replace them when signs of wear and

tear begin to show. Subsequently, the

bearings must be checked after every

10,000 running hours.

6.7 Dismounting of motor

Refer to figure 8 in the following.

Dismounting motor

1 Dismount any ducts on the inlet and

outlet sides.

2 Remove the screws (pos. 1) holding

the hub cap and remove the cap (pos.

2) itself.

3 Remove the rotor centre screw (pos. 3)

and the centre disc (pos. 4).

4 Dismount the rotor by means of a

puller fastened in the threaded holes

of the hub boss (pos. 5).

5 Depending on the length of the

installed motor cable; draw the cable

free of the fan casing in order to

handle the motor.

6 Support the motor. See table 3 for

max. motor weights.

7 Detach the motor from the motor shell

by removing the nuts and bolts (pos.

7a and 7b).

Notice:

Nuts holding motors

mounted in rear motor

shells are accessed through

the front motor shells.

8 Remove the motor (pos. 8).

6.8 Mounting of motor

Refer to figure 8 in the following.

Mounting motor

1 Mount the motor (pos. 8) and make

sure the motor shaft is concentrically

placed in the fan casing.

2 Insert and tighten the nuts and bolts

(pos. 7a and 7b). See table 7. “Motor

and flange bolt tightening torques”.

Notice:

Nuts holding motors

mounted in rear motor

shells are accessed through

the front motor shells.

3 Mount the rotor (pos. 6) on the motor

shaft by means of a tool fastened in

the threaded hole of the motor shaft.

The rotor hub must rest against the

motor shaft collar. Check that the

rotor can rotate freely, i.e. that the

blade clearance is the same

throughout the circumference of the

casing. Adjust the motor position if

necessary.

4 Use a feeler gauge to check that the

clearance between the rotor blade tips

and fan casing is the same throughout

the circumference and meets the

following requirements.

• Minimum 2 mm

• 10% of the motor shaft diameter

• Maximum 13 mm

Refer to the motor manufacturer’s

documentation for the shaft diameter.

5 Adjust the motor position with

reference to step 4.

6 Mount the centre disc (pos. 4) and the

rotor centre screw (pos. 3).

7 Mount the hub cap (pos. 2) and mount

the screws (pos. 1).

8 Connect the motor cable in the

terminal box and connect the ducts.

To start the fan follow the procedure

described in section “5. Start of

operation”.

6.9 Troubleshooting

In case of breakdowns, the following

checklists should be completed, before

calling for service.

Lacking performance

• Damper closed

• Ducts clogged

• Supply fan, if any, stopped

• Motor defective

• Motor disconnected

• Wrong direction of rotor rotation

Important:

Constant vibration

monitoring is mandatory

for ATEX category 2D

fans, i.e. fans operating in

zone 21.

Important:

Switch off the power and

disconnect the motor

cable in the terminal box,

before beginning work

on the rotor and motor.

Important:

When working with the

fan, avoid exposing parts

to shocks. Motor bearings

and other fan components

are vulnerable parts.

Important:

Replace lock washers and

nuts during fan assembly.

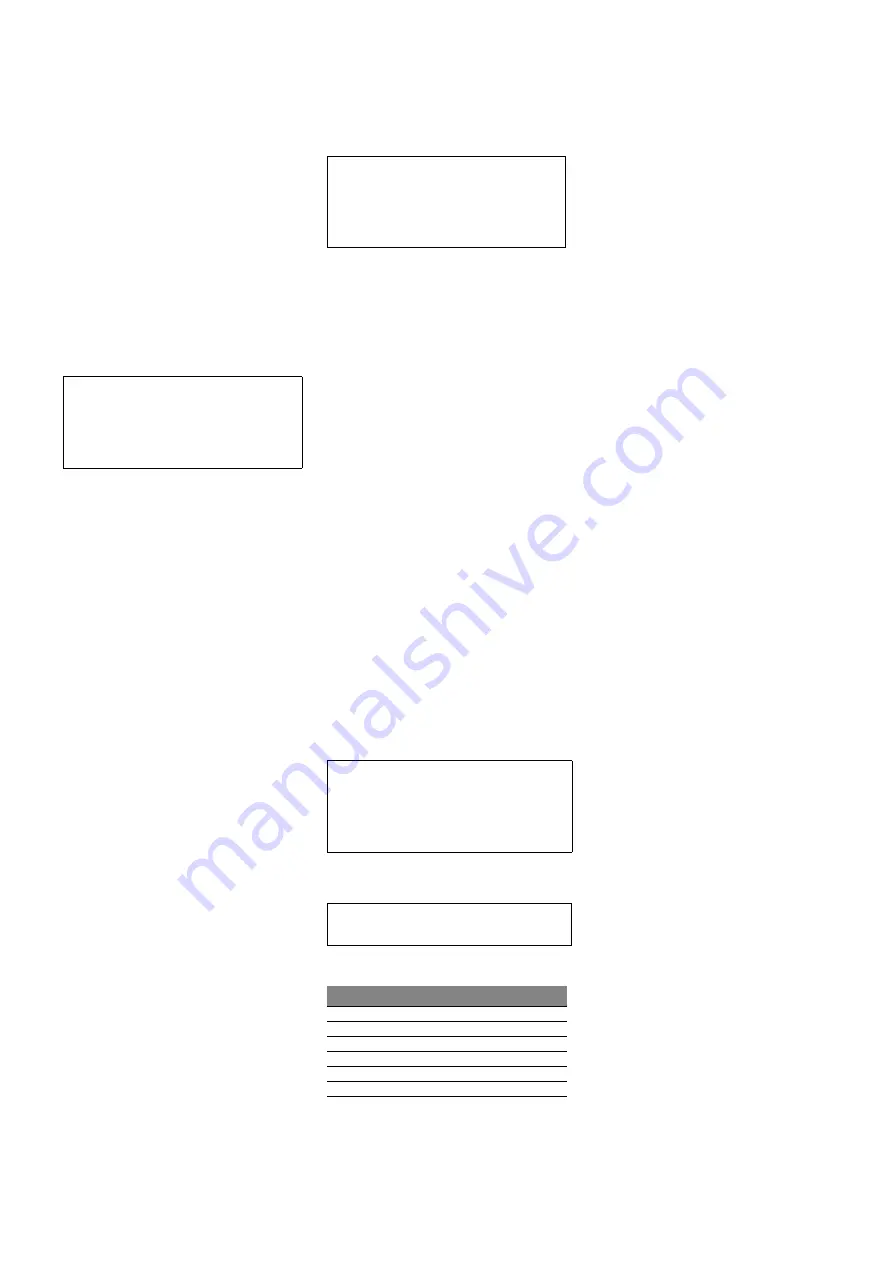

Size

Torque [Nm]

M6

12

M8

30

M10

60

M12

100

M16

230

M20

470

Table 7.

Motor and flange bolt tighten-

ing torques