WALL

INSTALLATION INSTRUCTIONS

|

31-00133

PCD7.LR-TR4x Wall Modules

|

3

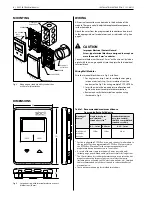

Fig. 5. Options for Wiring Multiple PCD7.LR-TR4x

Fig. 6. Terminal connections.

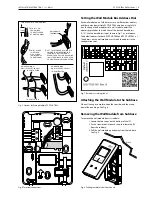

Each wall module on a Sylk bus must use a different bus address,

and there may be multiple PCD7.LR-TR4x wired on a single Sylk

bus. To change the bus address of a wall module, adjust the

address dipswitches to match that of the desired bus address

(1-15). Use the bus address label, shown in Fig. 7, as a reference.

The default address for both PCD7.LR-TR40 and PCD7.LR-TR42 is 1.

The address on the wall module must match the address in the

configuration tool.

Setting the Wall Module Bus Address Dial

Fig. 7. Bus address settings label.

When all wiring is complete, hook the top side, and then snap

down like on a hinge. See Fig. 8.

Attaching the Wall Module to the Subbase

To remove the wall module from its subbase:

1. Locate the two snaps on the bottom of the IFC .

2. Push a screwdriver into each snap to release the IFC

from the subbase.

3. Pull the wall module up and away from the subbase.

See Fig. 8.

Removing the Wall Module from Subbase

Fig. 8. Drilling template (view from above)

TO CONTROLLER

TWO WIRES INTO ONE TERMINAL

DAISY-CHAINING

MULTIPLE PCD7.LR-TR4x

TO CONTROLLER

TO PCD7.LR-TR4x

13 mm

STRIP 13 mm

FROM WIRES

TO BE ATTACHED

AT ONE TERMINAL.

1.

2.

TWIST WIRES

TOGETHER

WITH PLIERS

(A MINIMUM OF

THREE TURNS).

3.

CUT TWISTED END OF WIRES TO

5 MM BEFORE INSERTING INTO

TERMINAL AND TIGHTENING

SCREW. THEN PULL ON EACH WIRE

IN ALL TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

WALL MODULE

TERMINALS

HOME RUNNING

MULTIPLE PCD7.LR-TR4x