right fence scale

should read zero

straight-edge

SawStop Contractor Fence Assembly 7

0

3

10

6 0

7 0

8 0

4

5

9 0 10 0

1 0

2 0

3 0

0

1

2

4 0

3 0

2 0

1 0

6 0

5 0

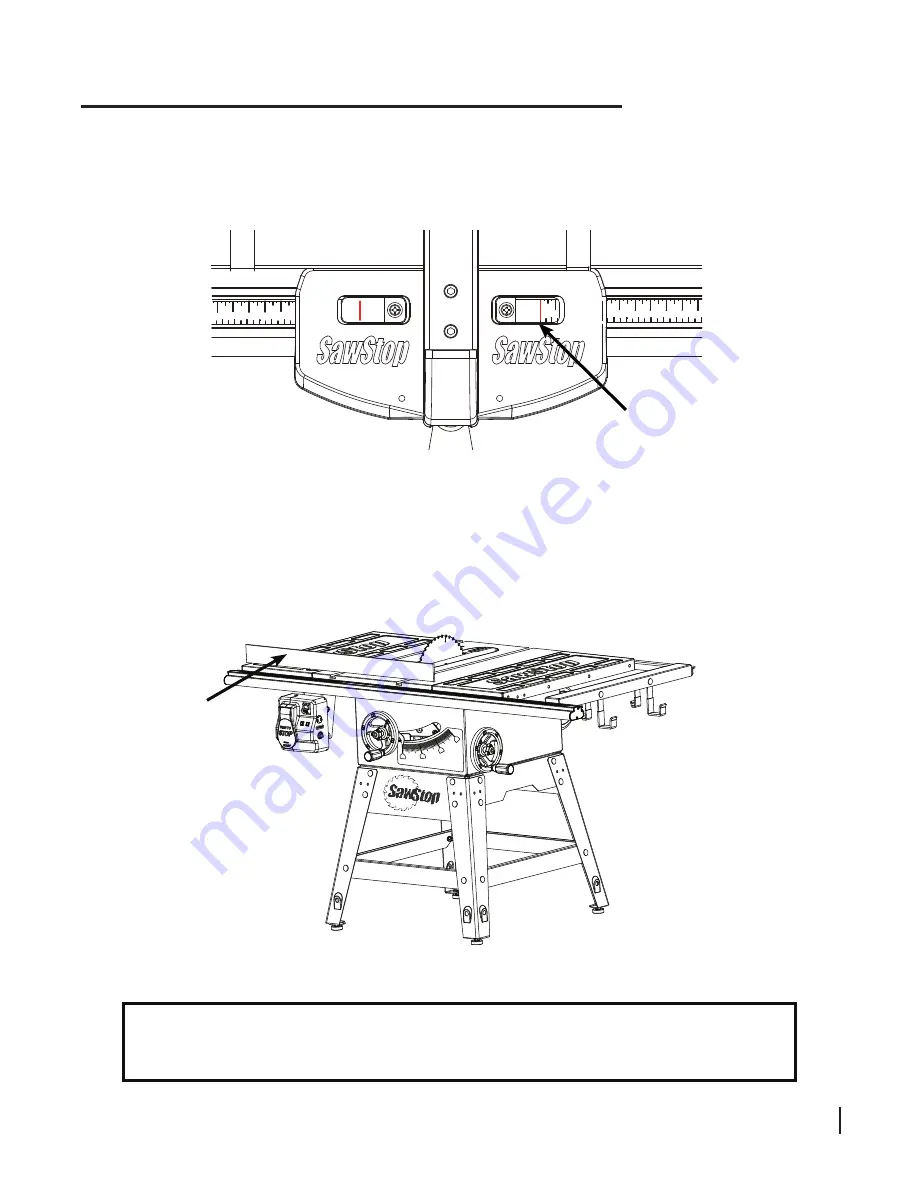

16. Use a straight-edge to level the front edge of the left extension wing to the cast iron table top (see Fig. 16).

You may have to pull up or push down on the outer edge of the extension wing. You also may need to remove

the fence from the table to provide clearance for the straight-edge. Be careful not to change the position of the

front rail. Once the front edge of the left extension wing is level, use a 13 mm wrench to fully tighten the nuts in

the front rail that extend through the left extension wing and the table top. Repeat this process to level the front

edge of the right extension wing and the material support shelf and then fully tighten the remaining nuts in the

front rail.

Fig. 16

Installing Your Fence Assembly

Congratulations, your fence assembly is now

installed and your saw is ready to use.

Fig. 15

15. With the fence unclamped and still against the right side of the saw blade, gently tap one end of the front rail

with a rubber hammer or mallet to move the rail to the right or left until the cursor on the right fence scale is

aligned with zero on the underlying ruler (see Fig. 15). Be careful to tap the front rail gently or the plastic cap

at the end of the rail may be damaged. Once the right fence scale reads zero the front rail is in the correct

position.

0

15

30

45

SawStop

10” Contractor Saw