Sauter GmbH

Tieringerstr. 11-15

Tel: +49-[0]7433- 9976-174

D-72336 Balingen

E-Mail: [email protected]

Fax: +49-[0]7433-9976-285

Internet: www. sauter.eu

Instruction Manual

TU_US

TU_US-BA-e-1110

2

-

Four transducer models are available for special

applications included coarse grain material and

high temperature applications.

-

Zero adjustment function

- Sound velocity calibration function

-

Two- point calibration function

-

Two measurement modes: Single point mode

Scan mode

-

Coupling status indicator showing the coupling

status

-

Battery indication indicates the rest capacity of

the battery

- “Auto sleep” and “Auto power off” function to

conserve battery’s life

Optional software to transfer the memory data to

PC

- Optional thermal mini- printer to print the

measured data via RS-232 port.

1.3 Measuring principle

The digital ultrasonic thickness gauge determines the

thickness of a part or a structure by accurately measuring

The time required for a short ultrasonic pulse generated by

a transducer to travel through the thickness of the material,

to reflect from the back or inside surface and be returned

to the transducer. The measured two-way transit time is

devided by two to account for the down-and-back travel

path, and then multiplied by the velocity of sound in the

material. The result is expressed in following relationship:

2

t

v

H

×

=

Where: H ---- thickness of the test piece

v ---- sound velocity in the material

t ---- the measured round-trip transit time

1.4 Configuration

No.

Item

Quan-

tity

Note

1 Main

body

1

2 Transducer

1 Model:

N05/90°

3 Couplant

1

4 Instrument

Case

1

5 Operating

Manual

1

6 Screwdriver

1

7

Alkaline battery

2

AA size

Stan-

dard

Con-

figu-

ration

8

9 Transducer:

N02

10 Transducer:

N07

11 Transducer:

HT5

See

Table3-1

12 Mini

thermal

printer

1

13 Print

cable

1

Optio-

nal

Con-

figu-

ration

14 DataPro

for

Thickness

Gauge

1 For

use

on the

PC

15 Communication

Cable

1

1.5 Operation conditions

Temperature: -20°C up to +60°C

Storage temperature: -30°C up to 70°C

Relative humidity:

≤

90%

In the surrounding environment any kind of vibrations

should be avoided, as well as magnetic fields, corrosive

medium and heavy dust.

2. Structure feature

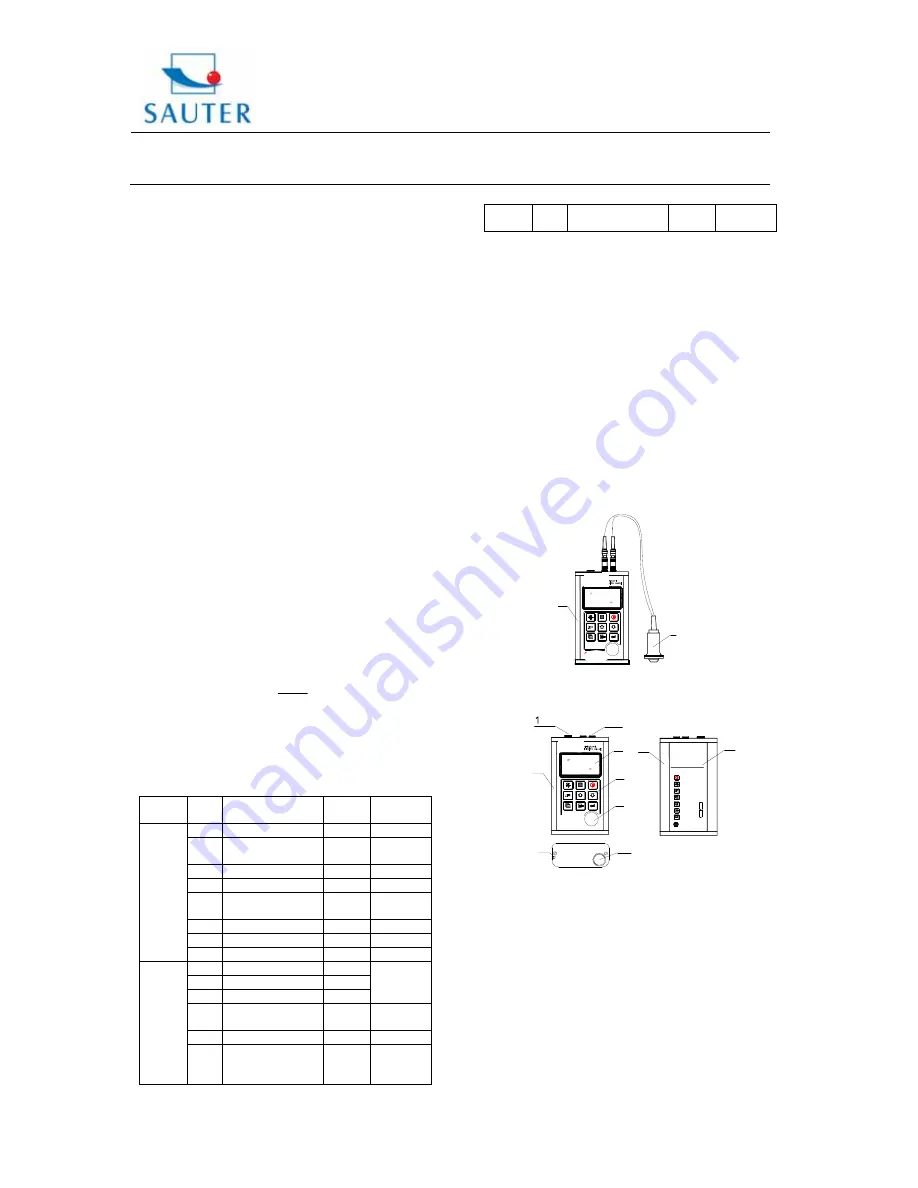

2.1 Instrument appearance

1 Main body

2 Transducer

2.2 Parts of the main body

1 Communication Socket

2 Aluminium case

3 Belt hole

4 Battery cover

5 Keypad

6 LCD Display

7 Socket of transducer (no polarity)

8 Control plate (inbuilt)

9 Aluminium case

10 Label

MT200

MiTec h

2

1

8. Enter

MiTech Inc. Ltd

5. Switch Selection

6. Save/Delete

7. Exit

3

MiTec h

4

8

2. Power On/Off

POWER: 2 X 1.5V

4. Probe Zero

OPERATION GUIDE

1. Plug in the transducer

3. Backlight On/Off

THICKNESS GAUGE

7

MT200

2

9

5

6

SN:

10