18

4000122704-1

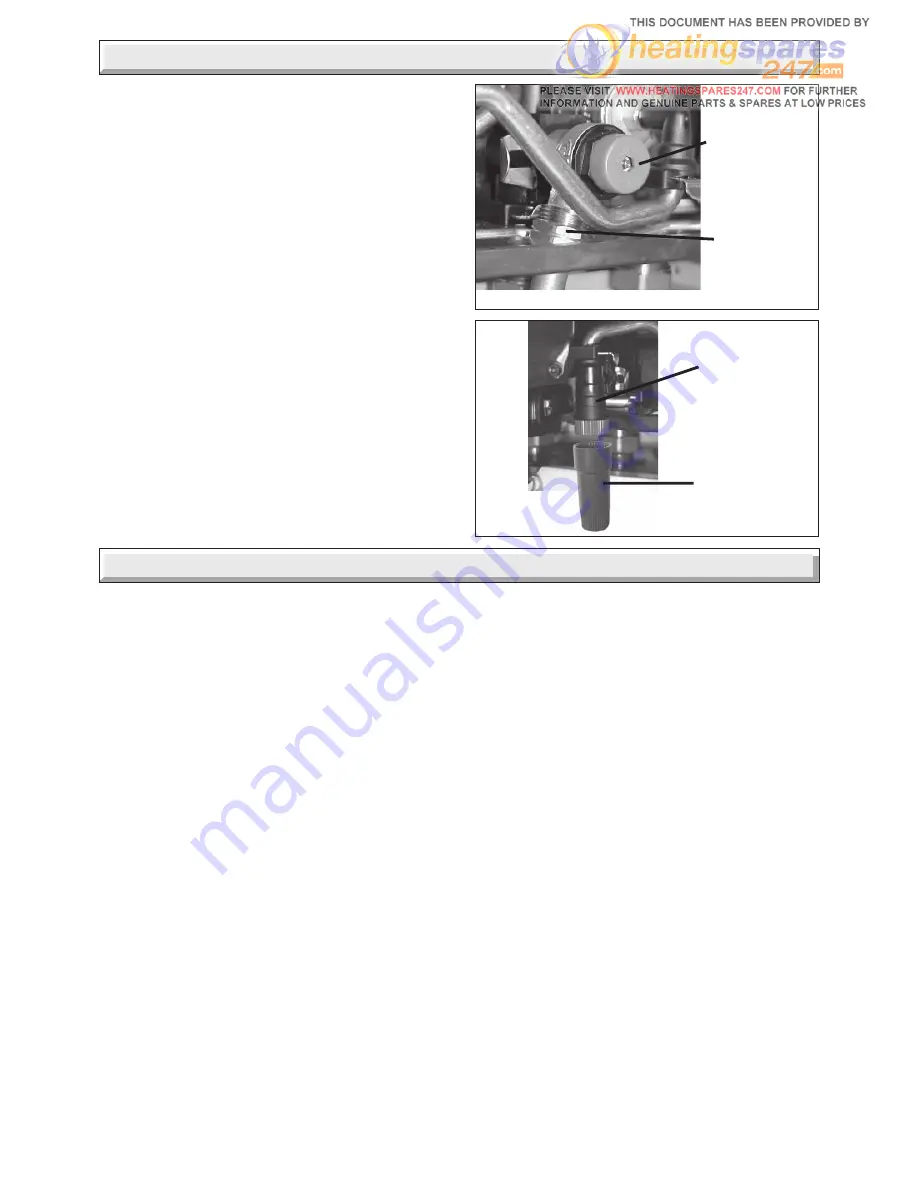

Diagram 9.4

9770

DISCHARGE

SAFETY

VALVE (3 bar)

DISCHARGE

SAFETY

VALVE PIPE

Diagram 9.5

10087

FILLING LOOP

EXTENSION

FILLING

DEVICE

9.4 Discharge safety valve, refer to diagram

9.4.

WARNING. It must not discharge above an entrance or window

or any type of public access area.

A short discharge pipe is supplied in the fittings pack, when fitted

to the safety valve it will end below the boiler. The discharge

pipe must be extended using not less than 15 mm o.d. pipe, to

discharge in a visible position outside the building, facing

downward preferably over a drain.

Note: Fit a compression fitting to facilitate service of the

appliance.

The pipe must have a continuous fall and be routed to a position

so that any discharge of water, possibly boiling or steam, cannot

create any danger to persons, damage to property or external

electrical components and wiring. Tighten all pipe connection

joints.

9.5 Filling loop extension F30E Only

Remove the filling loop extension knob from the fittings kit. Fit

to the filling device on/off knob this is a push fit, see diagram

9.5.

9 Boiler Installation

10 Horizontal Rear Flue Installation

The

Horizontal Rear flue - kit No A20097 is

suitable for installations that require a flue

length from 300 minimum to 930 maximum. If

longer flueing is required extensions and

bends are available, see note below. If a

shorter flue length is required the flue can be

cut to suit, see diagram 10.2 for minimum flue

length.

Important Note:Additional 1 metre extentions, 90

°

and 45

°

bends are available. The maximum extended flue is 3.5m. The

use of flue bends requires the flue lengths to be reduced by 1m.

for 90

°

and 0.5m. for 45

°

.

10.1 Horizontal Rear Flue kit of parts, refer to

diagram 10.1.

10.2 Cutting Rear Flue, refer to diagram 10.2.

Important Notes: After cutting ensure that there are no burrs.

10.3 Installation of Rear Flue assembly

• Fit rubber sealing collar (C) into groove at the outer end of the

flue assembly (A) and (B), see diagram 10.3.

• Fit flue assembly with attached rubber sealing collar into wall

from the outside with rubber sealing collar to the outside. Pull

assembly inwards to bring rubber sealing collar hard up against

external wall. The oposite end must exit the inner wall face by

30mm. see diagram 10.4. (1.)

• Fit the plastic internal flange (H) over the flue, push along the

pipe until engaged against internal wall, see diagram 10.4. (2.)

• Remove the backing from the wrap around self adhesive seal

(E) and carefully fit seal around the back end of the flue and

internal flange thats extending 30mm. from the inner wall face,

see diagram 10.4. (2.)

• Remove the backing from the wrap around self adhesive semi

rounded seal (D) and carefully fit seal around the front end of

the flue thats extending 30mm. from the inner wall face, see

diagram 10.4. (2.)

• Fit the ‘O’ ring (I) into the interface (G), apply a small amount

of silicone grease to the ‘O’ ring when fitting.

• Ease the interface (G) over the seals, see diagrams 10.4 (3.)

and 10.5.

• Important: Ensure that the flue if cut has no burrs that could

damage the ‘O’ ring. If the flue length is less than 500mm. fit the

flue restrictor (a) into the fan outlet, see diagram 10.6.

• Fit the interface sealing gasket (F) to the interface.

Preparing the boiler

• Lift the boiler up and engage boiler upper part onto the hanging

bracket.

• Fit the washers between the boiler pipes and the inlet and

outlet fittings on the fixing jig and connect the various couplings

between the boiler and jig.

Now the boiler is on the wall, slide forward the interface about

20mm. secure it on to the back of the boiler with the two screws

previously removed, see diagram 10.7.

• Engage the fan outlet into the interface, refit the fan, see

diagram 10.8.

F30E Only

F30E shown