The Sapling Company, Inc.

1633 Republic Road

Huntingdon Valley, PA 19006

215.322.6063 P.

215.322.8498 F.

www.sapling-inc.com

9

Installation Instructions

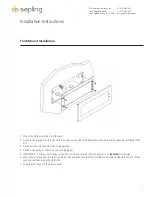

Plastic Double Mount Installation

*For metal mounting bracket: Use a wall anchor that can support 50 lbs or more with a maximum

screw size of 10/1.5”

q

Install metal mounting bracket -

First, remove the metal mounting bracket from the inside of the double mount base by unscrewing

the two (2) 6-32 x 1/2” screws located on the underside of the base (save these screws for step #5). Next, screw the metal mounting

bracket to the wall or ceiling in which the clocks are being installed. To mount to the switch box, screw the four (4) 6-32 x 1” screws

supplied in the assembly kit through the inner four holes of the metal mounting bracket. Use the outer four holes to mount anchors

to the wall (both anchors and screws for anchors not supplied in kit). For IP clocks, if using an Ethernet bracket (*as shown in the

diagram) use the two (2) 6-32 x 1/4” included in the assembly kit to mount the Ethernet bracket to the metal mounting bracket at this

point(Ethernet bracket not supplied in assembly kit).

Note: if using a plastic switch box, a ground wire must be routed through the switch box and into one (1) of

the four (4) metal mounting bracket screws in order to provide ground to the metal mounting bracket.

Note: the metal mounting bracket

MUST

be secured by both the screws going to the switch box

AND

the

anchors going into the wall.

w

Mount clock housings to pole -

Align the hole in the center each housing with one of the three holes on the mounting pole where

the wiring will be routed (the installer will chose which hole at the end of the pole to use based on how far they want the clock to sit

from the wall). Screw from the inside of the housing into the four holes surrounding the hole in the center of the housing using the four

(4) 8-32 x 7/16” screws supplied in the assembly kit (4 screws per clock), securing both housings to the mounting pole.

Note: end caps from one side of each clock must be removed to mount both clocks to the mounting pole.

Remove one end cap from each clock from the side in which the mounting pole enters the clock.

e

Screw both housings together -

Using the two (2) self tapping, 6-19 x 7/16” screws supplied in the assembly kit, screw both back

sides of the clock housings together (2 screws per clock).

r

Feed wiring through base and pole -

Take the wiring coming from the switch box and begin to feed it through the center of the

base of the mounting assembly until it emerges from the hole in the center of the clock housing. Make sure there is roughly 1.5’ - 2’

of wiring coming from the switch box. Perform this task for both clocks. If installing IP clocks, run bare Ethernet wire without an RJ45

connector and install the connector after it has been routed through the clock if possible (this will be much easier than running the wire

with the connector on). If not possible, make sure that there is no boot present in order for the connector to fit through the assembly.

If you are using an Ethernet bracket with the installation of IP clocks, the assembly of the clocks in steps 6 and 7 can be accomplished

before mounting the assembly to the wall in step 5 - making the overall installation more simple.

*instructions continued on next page