-9-

1. Receive the 16-step gray scale video signal with

Input 3 [VIDEO]

mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “

TP531

” (+) and

chassis ground (-).

4. Select group no. “

6

”, item no. “

11

” and change data

value to adjust the pedestal level and black level to be

the same level.

5. Connect an oscilloscope to test point “

TP501

” (+) and

chassis ground (-).

6. Select item no. “

12

” and change data value to adjust

the pedestal level and black level to be the same

level.

7. Connect an oscilloscope to test point “

TP561

” (+) and

chassis ground (-).

8. Select item no. “

10

and change data value to adjust

the pedestal level and black level to be the same

level.

Pedestal Lebel = Black Lebel

1. Receive the 16-step gray scale computer signal with

Input 1 [COMPUTER]

mode.

2. Enter the service mode.

3. Project only green light component to the screen.

4. Select group no. “

5

”, item no. “

11

” and change data

value to obtain the minimum flicker on the screen.

5. Project only blue light component to the screen.

6. Select item no. “

12

” and change data value to obtain

the minimum flicker on the screen.

7. Project only red light component to the screen.

8. Select item no. “

10

” and change data value to obtain

the minimum flicker on the screen.

A/D Offset adjustment

Common Center adjustment

[PC WHITE BALANCE ADJUSTMENT]

1. Receive the 16-step gray scale computer signal with

Input 1 [COMPUTER]

mode.

2. Enter the service mode.

3. Select group no. “

4

”, item no. “

7

” (Red) or “

8

” (Blue),

and change data values respectively to make a prop-

er white balance.

[AV WHITE BALANCE ADJUSTMENT]

4. Receive the 16-step gray scale video signal with

Input 3 [VIDEO]

mode.

5. Enter the service mode.

6. Select group no. “

4

”, item no. “

7

” (Red) or “

8

” (Blue),

and change data values respectively to make a prop-

er white balance.

Confirm that the same white balance is obtained in

video and computer input.

White Balance adjustment

If you find the color shading on the screen, please

adjust the white uniformity by using the proper comput-

er and “Color Shading Correction” software supplied

separately. The software can be ordered as follows;

COLOR SHADING CORRECTION SOFTWARE

Service Parts No.

645 051 2308

NOTE ON WHITE UNIFORMITY

ADJUSTMENT

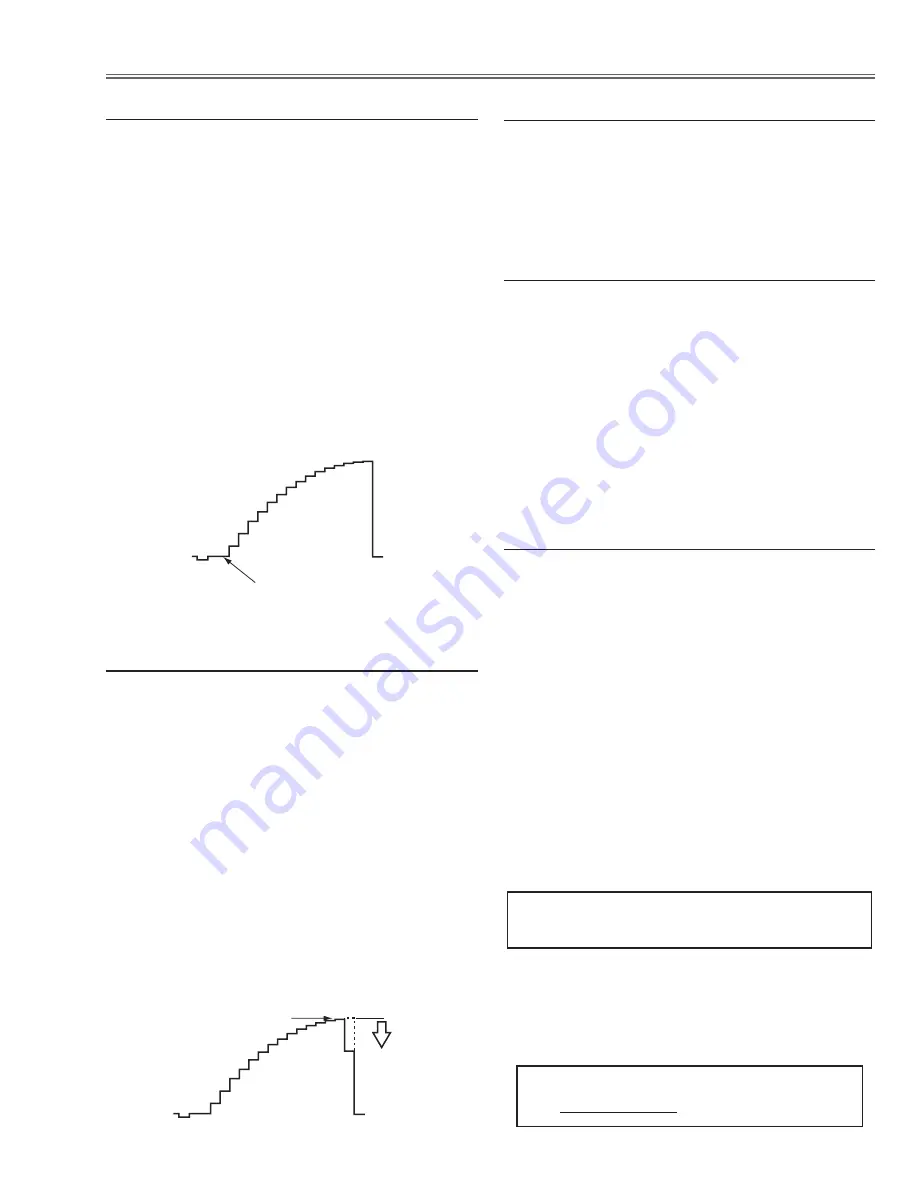

1. Receive the 16-step gray scale video signal with

Input

3 [VIDEO]

mode.

2. Enter the service mode.

3. Connect an oscilloscope to test point “

TP531

” (+)

and chassis ground (-).

4. Select group no. “

4

”, item no. “

4

” and set data value

to “600”, and then decrease data to adjust waveform

“a” to be minimum amplitude.

5. Connect an oscilloscope to test point “

TP501

” (+)

and chassis ground (-).

6. Select item no. “

5

” and set data value to “600”, and

then decrease data to adjust waveform “a” to be mini-

mum amplitude.

7. Connect an oscilloscope to test point “

TP561

” (+)

and chassis ground (-).

8. Select item no. “

3

” and set data value to “580”, and

then decrease data to adjust waveform “a” to be mini-

mum amplitude.

White Level

(a)

Video Gain adjustment

1. Receive the 16-step gray scale video signal with

Input 3 [VIDEO]

mode.

2. Enter the service mode.

3. Select group no. “

4

”, item no. “

6

” and change data

value to reproduce the proper gray scale picture on

the screen.

Video Gamma Shift adjustment

Electrical Adjustments

Содержание PLC-XP46

Страница 42: ...MA8 XP4602 MA8 XP46L01 Electrical Parts List 42 Key No Part No Description Key No Part No Description ...

Страница 45: ...MA8 XP4602 MA8 XP46L01 45 Mechanical Parts List 51 a 51 43 43 51 b 23 a 23 b 23 Model PLC XP46 only ...

Страница 47: ...MA8 XP4602 MA8 XP46L01 47 Optical Parts List 46 58 45 45 53 a Red 53 b Green 53 c Blue 53 46 46 46 53 d ...

Страница 49: ...MA8 XP4602 MA8 XP46L01 49 Mechanical Parts List ...

Страница 50: ...MA8 XP4602 MA8 XP46L01 Mechanical Parts List 50 ...

Страница 51: ...MA8 XP4602 MA8 XP46L01 51 Mechanical Parts List ...

Страница 52: ... MK3AA Jun 2004 BB 400 Printed in Japan SANYO Electric Co Ltd ...

Страница 56: ...Diagrams Drawings PLC XP46 PLC XP46L ...