- 43 -

Service Adjustment

1. Enter the service mode.

2. Connect a digital voltmeter to test point “

TPFANA

” (+) and

chassis ground (-). Select group no. “

250

”, item no. “

0

” and

change data value to adjust voltage to be

5.0 ±0.1V

.

3. Connect a digital voltmeter to test point “

TPFANB

” (+)

and chassis ground (-). Select item no. “

2

” and change data

value to adjust voltage to be

5.0 ±0.1V

.

4. Connect a digital voltmeter to test point “

TPFANC

” (+)

and chassis ground (-). Select item no. “

4

” and change data

value to adjust voltage to be

5.0 ±0.1V

.

5. Connect a digital voltmeter to test point “

TPFANA

” (+)

and chassis ground (-). Select item no. “

1

” and change

data value to adjust voltage to be

13.5 ±0.1V

.

6. Connect a digital voltmeter to test point “

TPFANB

” (+)

and chassis ground (-). Select item no. “

3

” and change data

value to adjust voltage to be

13.5 ±0.1V

.

7. Connect a digital voltmeter to test point “

TPFANC

” (+)

and chassis ground (-). Select item no. “

5

” and change data

value to adjust voltage to be

13.5 ±0.1V

.

1. Fan Control adjustment

* Before setting, you need to check which type of LCD panel is

placed on the projector according to the item "LCD Panel/Prism

Ass'y removal" in the chapter "Optical Parts Disassembly".

1. Enter the service mode.

2. Panel Type Check

Select group no. “

290

”, item no. “

0

”. Check the data value

as follows;

Data value: 0

For L-Type of LCD Panel

Data value: 20 For R-Type of LCD panel

3. Panel Type Setting

Select group no. “

290

”, item no. “

1

” and change data val-

ue from 10 to 0 or 20 depending on your LCD Panel type.

When the data value reaches 0 or 20, it returns to 10 quick-

ly. The gamma-characteristics changes according to your

selection.

2. Panel Type Check and Setting

1. Enter the service mode.

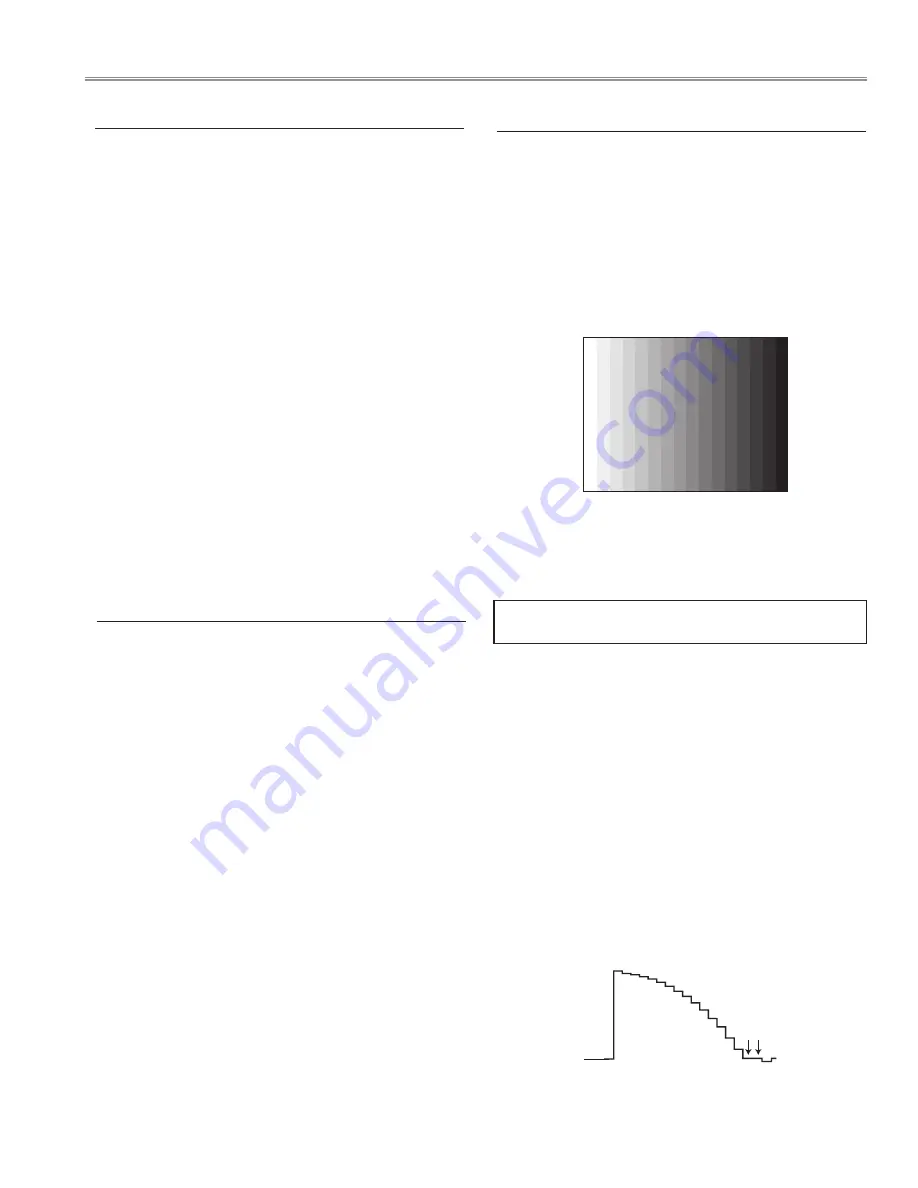

2. Receive the 16-step grey scale computer signal with

Com-

puter1 [RGB]

mode.

Lamp control

Normal

mode.

G-sync Off

3. To start the auto-calibration for PC adjustment, select

group no. “

260

”, item no. “

0

” and then change data value

from “

0

” to “

1

”. After the auto-calibration completed, "OK"

will appear on the screen.

3. Auto Calibration adjustment [PC]

White 100%

Black 100%

Pedestal adjustment [PC]

1. Enter the service mode.

2. Receive the 16-step grey scale computer signal with

Com-

puter1 [RGB]

mode.

3. Connect an oscilloscope to test point “

TP35G

” (+) and

chassis ground (-).

4. Select group no. “

0

”, item no. “

0

” and change data value

to adjust the pedestal level and black level to be the same

level.

5. Connect an oscilloscope to test point “

TP35R

” (+) and

chassis ground (-).

6. Select item no. “

1

” and change data value to adjust the

pedestal level and black level to be the same level.

7. Connect an oscilloscope to test point “

TP35B

” (+) and

chassis ground (-).

8. Select item no. “

2

” and change data value to adjust the

pedestal level and black level to be the same level.

P

edestal Lebel

Blac

k Lebel

Below adjustments are performed when the above auto

calibration is failed.

Содержание PLC-XL50A

Страница 78: ... 78 IC Block Diagrams BA7078 Sync Separator IC5301 AN5870 Signal Switch IC5201 ...

Страница 79: ... 79 FA5502 P F Control IC601 HIN202EIB RS 232C Driver IC3801 IC Block disgrams ...

Страница 80: ... 80 L3E07110 LCD Driver Gamma Correction IC401 L3E06150 D A S H LCD Driver IC501 IC531 IC561 IC Block disgrams ...

Страница 81: ... 81 L3E01060 Level Shift IC2501 IC2531 IC2561 M62334 DAC IC3501 IC Block disgrams ...

Страница 82: ... 82 NJW1141 Audio Control IC5001 PW190 Scaler IC301 IC Block disgrams ...

Страница 107: ... 107 S4 S4 S4 S4 S5 S5 C15 C16 C16 C17 C17 C18 C18 Mechanical Parts Location ...

Страница 109: ... 109 Integrator Lens In L09 L14 Optical Parts Location Relay Lens Out S6 S6 S6 S6 ...

Страница 110: ... 110 L03 L13 L04 L11 L17 L18 L08 L12 L12 L07 L05 L06 110 Optical Parts Location In the Optical Unit ...

Страница 112: ...SM5111155 00 PLC XL50A Oct 2009 DC 200 Printed in Japan SANYO Electric Co Ltd ...