−

10

−

4. ELECTRICAL ADJUSTMENT

4-1. Adjustment of Thermal Printer Head Resistance

Value

1.Install the ribbon cassette and paper tray, and turn the power

on without inserting a media card.

2.While pressing the LCD operation "+" button and "-" button

(to the right of the MENU button below the LCD) simulta-

neously for two seconds or more, press the Print button to

switch to the adjustment menu mode.

The LCD panel displays "set-test."

3.Press the LCD operation "+" button six times, and select the

resistance value settings menu.

The LCD panel displays "set-res."

4.Press the MENU button, and to switch to resistance value

setting mode.

The LCD panel displays the resistance value (eg.: set-6210).

5.Set the resistance value on the LCD panel to the resistance

value displayed on the thermal head using the LCD opera-

tion "+" button and "-" button and the COPIES "+" button and

"-" button.

The first digit is set using the COPIES "+" button, the second

digit using the COPIES "-" button, the third digit using the

LCD operation "+" button, and the fourth digit using the LCD

operation "-" button.

The number displayed changes by 1 each time one of the

buttons is pressed, and after 9 comes 0.

6.End setting the resistance value by pressing the MENU but-

ton.

The LCD panel displays "set-end."

7.Turn the power off.

4-2. Firmware Updating and Correction Data Updat-

ing

NOTE: Firmware updating and correction data updating can-

not be done at the same time. Furthermore, if data is

stored on both sides of a firmware update media card,

updating cannot be performed.

1.Install the ribbon cassette and paper tray, and turn the power

on with the media card containing the firmware inserted.

2.Set to index mode using the MENU button, and while press-

ing the LCD operation "+" button and "-" button (to the right

of the MENU button below the LCD) simultaneously for two

seconds or more, press the Print button to switch to the ad-

justment menu mode.

The LCD panel displays "set-test."

3.Press the LCD operation "+" button one time to switch to the

firmware update menu.

The LCD panel displays "set-up."

4.Press the MENU button to start the firmware update.

The LCD panel displays "f-up" or "h-up."

While the firmware is updating, the ink LED lights.

Do not remove the card while the firmware is updating.

The LED will go off when the firmware update is complete,

and the unit will return to index mode.

5.Check to be sure that the ink LED has gone off and that the

unit has returned to index mode. Then remove the media

card and restart.

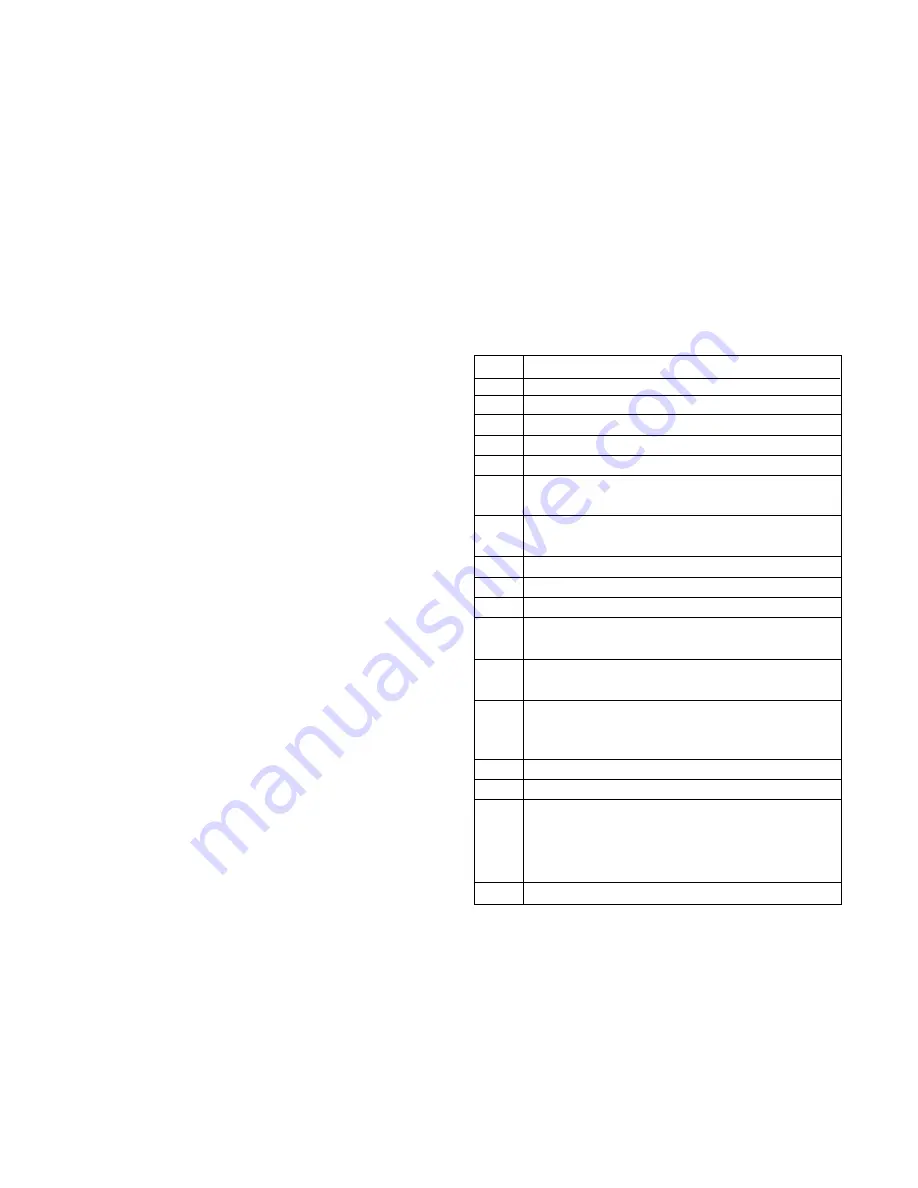

4-3. Checking Error Codes

When the LCD panel displays Err, press the LCD operation

"+" button and "-" button (to the right of the MENU button be-

low the LCD) simultaneously to display the error code.

CORD ERROR

21:

No ribbon

26:

Ribbon size and paper size are different

20:

Other ribbon jam

23:

End of ribbon

25:

Timeout detecting start of ribbon

24:

Ribbon turning during paper ejection (possible

ribbon jam)

31:

No paper (even with a paper feed operation, the

edge of the paper does not come)

30:

Other paper jam

32:

Error measuring length (not regular paper size)

33:

Paper set in tray differs from paper setting

37:

L-size paper (89 x 127 mm) ejection operation has

been done, but the eject switch does not turn ON

38:

Ejection operation has been done, but the eject

switch does not turn ON

1:

Strove over error (When printing photos, the time

power is applied to the print head exceeds the line

time)

10:

Head cannot move (two second timer)

15:

Failure returning head to standby

11:

Front edge of paper does not pass "paper top

detection sensor" even though the platen drive

motor moves the prescribed number of steps. Top

of paper cannot be detected

100:

Head abnormally hot