18

OPERATING INSTRUCTIONS

Calibration of temperature sensor

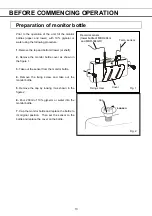

The temperature sensors are attached to the monitor bottles. Follow the instructions below for proper

calibration of temperature sensor.

1.

Remove the monitor bottle cover as shown in

the figure.

2.

Remove the sensor to be calibrated from the

monitor bottle. Please note that MBR-304G and

MBR-304GR also has a sensor for the temperature

recorder in the left side of the lower monitor bottle.

3.

Prepare a bottle or beaker with a solution of

crushed ice and cold water. Agitate the mixture

thoroughly.

4.

Put the sensor to be calibrated in the mixture.

5.

Select the temperature display by pressing

temperature display key to show the proper

temperature. While continuously agitating the ice

water mixture, monitor the temperature indicated

on the display of the sensor to be calibrated.

6.

Wait for the temperature on the display to stabilize. If the display is not 0

o

C, calibrate using the

following procedure. If the display does indicate 0

o

C, proceed to step 7.

6-1. Press the CAL key for approximately 5 seconds until C00 is displayed.

6-2. Enter the code of the probe to be calibrated using the numerical value shift key ( ).

Upper chamber temperature sensor code is C01.

Lower chamber temperature sensor code is C02.

6-3. Press the CAL key. (This makes temperature display 0

o

C)

This key operation is canceled with the buzzer if the sensor temperature deviates over +/- 1.5

o

C.

In this case, consult with Sanyo dealer or service personnel.

6-4. The digital display will revert back to current chamber temperature. The calibration that was

entered in the previous step should now have an effect on the temperature display.

The digital display should now show indicate 0.0

±

0.2

o

C, if not, repeat step 6.

7.

Take the sensor out of the ice water solution and wipe with a soft cloth.

8.

Attach the sensor back into the monitor bottle by reversing the procedure in step 1 and 2.

*

For the span adjustment, contact your service personnel.

Cover

Fixing screw

Recorder sensor

(lower bottle of MBR-304G

and MBR-304GR)

Temp. sensor