NOTES:

●

If oil fails to appear at oil sender hole within 30 seconds

of starter operation, allow the starter to cool. verify that oil

line routing is correct and that the oil tank is full to the

proper level

●

Oil pressure indicator lamp should light when ignition is

turned on. Lamp will go out after engine is started and there

is oil pressure at the switch in the crankcase.

CAUTION - Avoid excessive time of starter

engagement. Overheating of starter motor will result in

damage. Oil pump should prime and deliver oil to the

oil sender hole within 30 seconds.

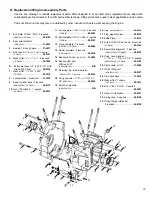

J. Exhaust System

NOTE - The engine must be correctly mounted into the

frame before the exhaust system is installed.

1.

Place new woven-metal gasket into exhaust ports

of cylinder heads.

2. Inspect the exhaust pipe header flanges and

retaining rings. Replace if distorted, warped, or

otherwise damaged.

3.

Apply a high-temp. anti-seize lubricant to threads

of exhaust studs at cylinder heads.

4. Install exhausts to cylinder heads. Hand tighten

exhaust stud nuts.

5. Attach exhausts to lower mounting bracket. Shim if

necessary. Hand tighten mounting hardware.

6. Tighten exhaust flange nuts at head to 60-80 in-lbs.

WARNING - In some instances, brake master cylinder

must be spaced out from frame to clear crankcase.

UNDER NO CIRCUMSTANCES SHOULD MASTER

CYLINDER OR BRAKE LINE BE ALLOWED TO

CONTACT EXHAUST PIPE IN FINAL INSTALLATION.

Heat transferred to brake fluid may expand and cause

brakes to seize, resulting in possible fire hazard and

loss of control of motorcycle with injury or death to

rider and others.

NOTE - Make certain that the exhaust system is not pre-

loaded, or in a bind, at the lower mounting points. Make all

spacing adjustments prior to final-tightening of the upper

exhaust mounting hardware at the cylinder heads. Failure

to follow this procedure may cause excessive vibration and

result in failure of exhaust pipes or mounting hardware.

K. Initial Start-Up And Engine Break-In

NOTE - engines are designed for high performance and as

such are not as tolerant of inadequate break-in as stock or

lower performance engines. Correct break-in will assure

longer engine life and will prevent unnecessary engine

damage. Engine damage caused by improper break-in is

not covered under the S&S warranty.

1. Initial

start-up

1. For the initial start up, the fuel and ignition

systems should be adjusted to their baseline

settings. (Baseline settings allow the bike to

start and run, and are the starting point for

tuning.) This is adequate for the initial start-up

and heat-cycling of the engine.

NOTE - Because there are several ignition and fuel system

combinations possible with the S&S Twin Cam style

engine, baseline settings are not listed here. Refer to the

appropriate ignition or fuel system instruction sheet.

2. Run engine approximately one minute at 1250-

1750 rpm. DO NOT crack throttle or subject to

any loads during this period as head gaskets

are susceptible to failure at this time. During

this time, check to see that oil pressure is

normal, and that oil is returning the oil tank.

3. Shut off engine and thoroughly check for any

oil leaks, fuel leaks, or other problems. Let

engine cool to the touch.

4. After engine has cooled, start up again and

allow the motor to build some heat. Engine

should not be run longer than three to four

minutes. When the cylinders become warm/hot

to the touch (approximately 150°) shut the motor

down and let it cool to room temp. Follow the

same cautions as for the initial start-up, and

continue to watch for problems.

5. Repeat this procedure 3 or 4 times. Each

successive time it should take slightly longer to

warm up and you can increase the temperature

slightly each time. You can be more liberal each

time with the rpm, gently vary rpm continuously

from idle up to 2500 rpm in the final cycle. The

motor should not reach full operating

temperature during these cycles. Do not allow

engine temperature to become excessive.

15

Содержание Motorcycle Accessories

Страница 20: ...Because every industry has a leader...