CWFL-800/1000/1500 Series

3

Thank

you

for

using

the

machine

from

GUANGZHOU

TEYU

ELECTROMECHANICAL CO., LTD. Please read the installation instructions

carefully before installing and operating and keep it properly.

This installation instructions is not a quality assurance. GUANGZHOU TEYU

ELECTROMECHANICAL CO., LTD reserves the right to the interpretation of

correction of typographical errors, improper mentioned information and product

improvement. The amended content will be reprinted in installation instructions

without notice in advance.

<1> Cautions

1. Please ensure that the power supply and electrical outlet are in good contact

and the earth wire must be firmly grounded!

2. Please make sure there is stable and normal voltage for the working chiller!

As the refrigeration compressor is more sensitive to the power supply and

voltage, so the operating voltage of our standard product is of 210 ~ 240V (110V

model is of 100 ~120V). If you do need a wider operating voltage range,

customization is available for us.

3. Unmatched power frequency can cause the chiller damage!

Please choose model of 50Hz or 60Hz according to actual circumstance.

4. To protect the pump, it’s strictly forbidden to run the chiller without water in the

storage water tank!

The new machine is packed after draining whole water in the tank, so please

make sure the tank has water inside before machine starting, otherwise it’s

easily to have the pump damaged. When the water level is below the green

(NORMAL) range of the water level gauge, the cooling capacity of our chiller

will go down slightly. Hence please ensure the water level is within the green

(NORMAL) range. To drain through circulating pump is strictly prohibited!

5. Please be sure that the air inlet and air outlet are in good ventilation!

There must be at least 50cm from obstructions to the air outlet which is in the

back of the cooler, and should leave at least 30cm between obstructions and

the side air inlet.

6. The filter gauze must be regularly cleaned!

It’s essential to remove and wash the dust gauze regularly, otherwise chiller

malfunction can be caused by serious blockage.

7. Please pay attention to the effect of the condensate water!

With greater ambient humidity, when the water temperature is lower than the

ambient temperature, the condensate water will generate on the surface of

water circular pipes and the cooled components. If above circumstance

appears, it is recommended to set a higher water temperature or keep pipes

and cooled parts warm.

8. This product is an industrial equipment.For professional use only.

Содержание CWFL-800

Страница 1: ...CWFL 800 1000 1500 DUAL TEMPERATURE INDUSTRIAL CHILLER USER MANUAL...

Страница 15: ...CWFL 800 1000 1500 Series 15 CWFL 800 1000 1500...

Страница 16: ...CWFL 800 1000 1500 Series 16 17 18 19 20 23 24 25 28...

Страница 17: ...CWFL 800 1000 1500 Series 17 1 2 210 240V 110V 100 120V 3 50Hz 60Hz 4 NORMAL NORMAL 5 50cm 30cm 6 7 8...

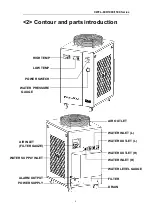

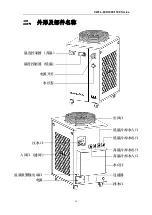

Страница 18: ...CWFL 800 1000 1500 Series 18...

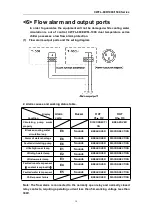

Страница 19: ...CWFL 800 1000 1500 Series 19 1 2 3 4 1 2 3 4 5 6 CWFL 800 1000 1500 20...

Страница 22: ...CWFL 800 1000 1500 Series 22 5 SET PARAM Set 1 2 2 25 RST 20 6 1 SET 00 PAS 8 SET F0 2 RST 20 SET 1 2 F0 3 F1...

Страница 24: ...CWFL 800 1000 1500 Series 24 CWFL 800 1000 1500 1 2 H1 H2 H1 H3 E6 E6 E6 E1 E2 E3 E4 E5 5A 300V...

Страница 28: ...CWFL 800 1000 1500 Series 28 E6 E6 E2 E1 40...