- -

3

D-1 Routine inspection items:

1.

Depress the button switch and let the hoist run idle, check if the upward and downward

operation are normal?

2.

Is the hoist operation smooth? Is there abnormal noise when it is with load?

3.

Check if the chain is oiled or damaged?

4.

Is the brake operation normal when the winding is stopped?

5.

Is the lower hook wasily rotating?

D-2 Regular inspection items:

1.

Inspection of LINK chain

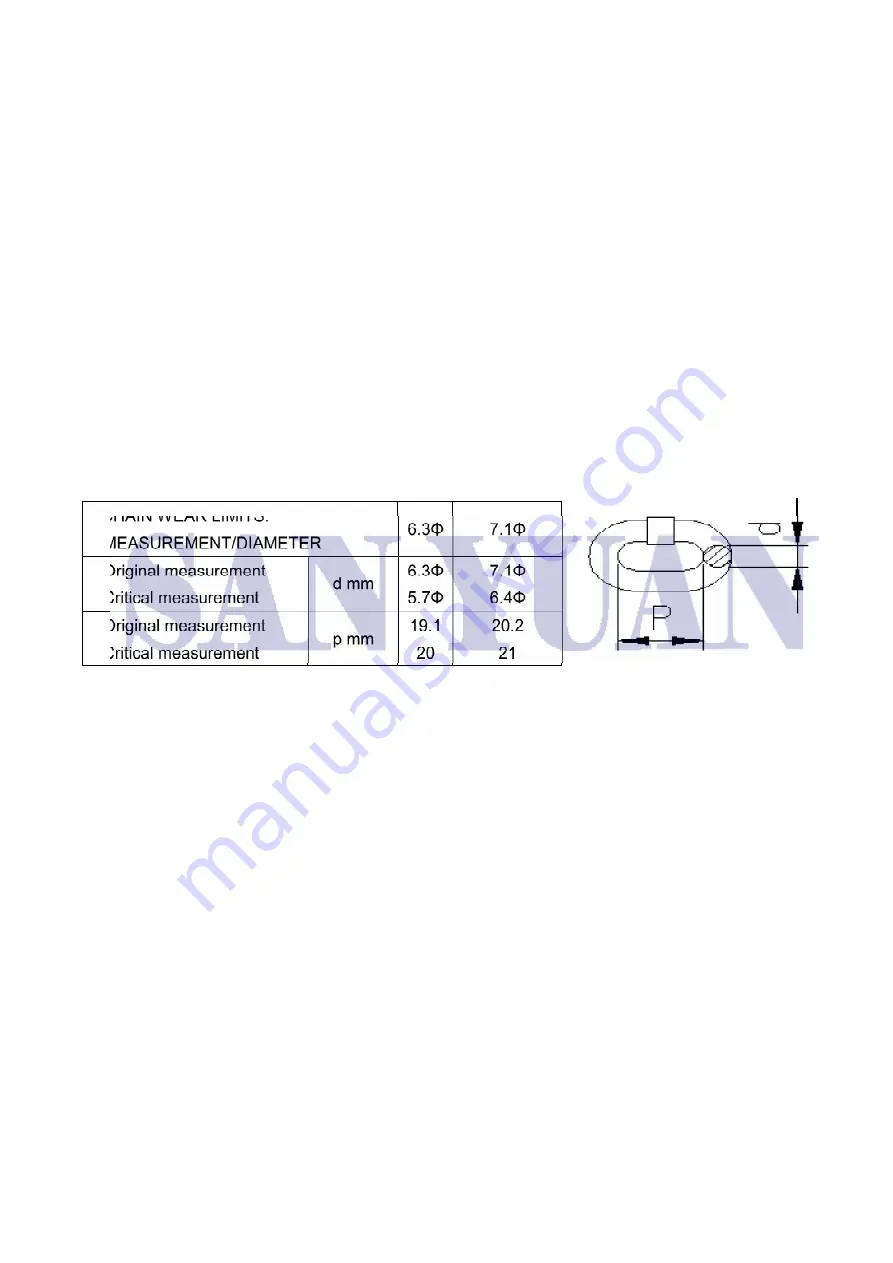

LINK chain is the most important part of the electrical chain hoist, which is made of special

alloy steel with heat treatment. The purpose is to withstand wear and tension. In case the

surface is dried and rusted, it will cause interwoven chains which may break. Therefore,

the surface must be oiled frequently (use normal lubricating oil). In case the chain is

deformed, cracked, elongated, worn, in excess of the following standards, new parts

must be replaced:

CHAIN WEAR LIMITS:

MEASUREMENT/DIAMETER

6.3

7.1

Original measurement

6.3

7.1

Critical measurement

d mm

5.7

6.4

Original measurement

19.1

20.2

Critical measurement

p mm

20

21

2.

Inspection of gear:

a.

Regular replacement of lubricating oil in the gearbox.

b.

Check if the gear surface is cracked or worn.

3.

Inspection of hook:

a.

In case of abnormal deformation, damage or breakage at the opening of the hook, it

must be replaced with new.

b.

In case the wear extent of the hook is in excess of 10%, it must be replaced with a

new part.

4.

Inspection of pushbutton switch:

a.

Are the inner and outer screws of the pushbutton switch loosened? Is the electric

wire damaged?

b.

Is there foreign substance between the contact points? Are the contact points

abnormally worn?

5.

Inspection of main unit:

a.

Is the wiring system in the main unit secured? Is the electric wire aged or damaged?

b.

Are the inner or outer screws of the main unit loosened?

c.

Is the panel or casing of the main unit deformed?