22

Installation Procedure

English

Installation Pr

oc

edur

e

2

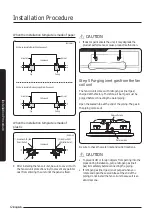

Selecting the crimping terminal lug

• Select the crimping terminal lug based on the

nominal cross-sectional size of the power cable.

• Cover the connection part of the power cable and

the crimping terminal lug to insulate it.

Silver solder

B

d2

F

L

t

E

d1

D

Nominal cross-

sectional size

Nominal diameter

of thread

B

D

d1

E

F

L

d2

t

Basic

size

Tolerance Basic

size

Tolerance Basic

size

Tolerance Min. Min. Max. Basic

size Tolerance Min.

1.5

4

6.6

±0.2

3.4

+0.3

-0.2

1.7

±0.2

4.1

6

16

4.3

+0.2

0

0.7

4

8

2.5

4

6.6

±0.2

4.2

+0.3

-0.2

2.3

±0.2

6

6

17.5

4.3

+0.2

0

0.8

4

8.5

4

4

9.5

±0.2

5.6

+0.3

-0.2

3.4

±0.2

6

5

20

4.3

+0.2

0

0.9

3

Specifications of the terminal blocks

(Unit: mm)

AC power:

M4 screw

Communication:

M3 screw

Communication:

M3.5 screwELB

11

13

18

6.62

7.62

10

7.5

9.0

13

.8

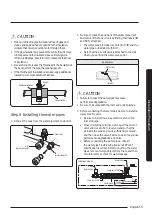

CAUTION

• When installing the product, be sure to install a 2-way

electric valve on the water inlet pipe.

When connecting a 2-way electric value, be sure to

check the correct sub PBA terminals as shown in the

figure below.

Incorrect terminal connection may cause product

malfunction. (Valve: Purchased at site)

– Specification: AC 220 to 240V (Operating current

must be 0.3A or less.)

– Applicable type: ON / OFF startup contact

• The standard specification is that the power supply for

the fan coil unit should be separate from that for a heat

source such as a chiller.

N

N

1-NO 1-NC

N

2-NO 2-NC

Wiring diagram when connecting a 2-way valve

2-Way valve1

(installed on site)

2-Way valve2

(installed on site)

Содержание AGTN1DKH Series

Страница 41: ...41 English Appendix Memo ...

Страница 42: ...42 Memo English Appendix ...

Страница 43: ...43 English Appendix ...

Страница 44: ...DB68 09309A 00 ...