7 of 9

Specifications subject without notice

Edition: November 2017

Operating instructions BA 10a-02_EN

Prior to installation, carefully clean the valve and the connecting section of the pipeline from dirt, especially hard foreign

material.

Make sure, in particular, that flange facings and any flange gaskets used are free from any dirt prior to installation.

Note

The valve must be inserted in the gap between the pipe flanges with the butterfly disc in the closed position.

Otherwise, the butterfly disc could be damaged and the valve will not shut tightly.

Note

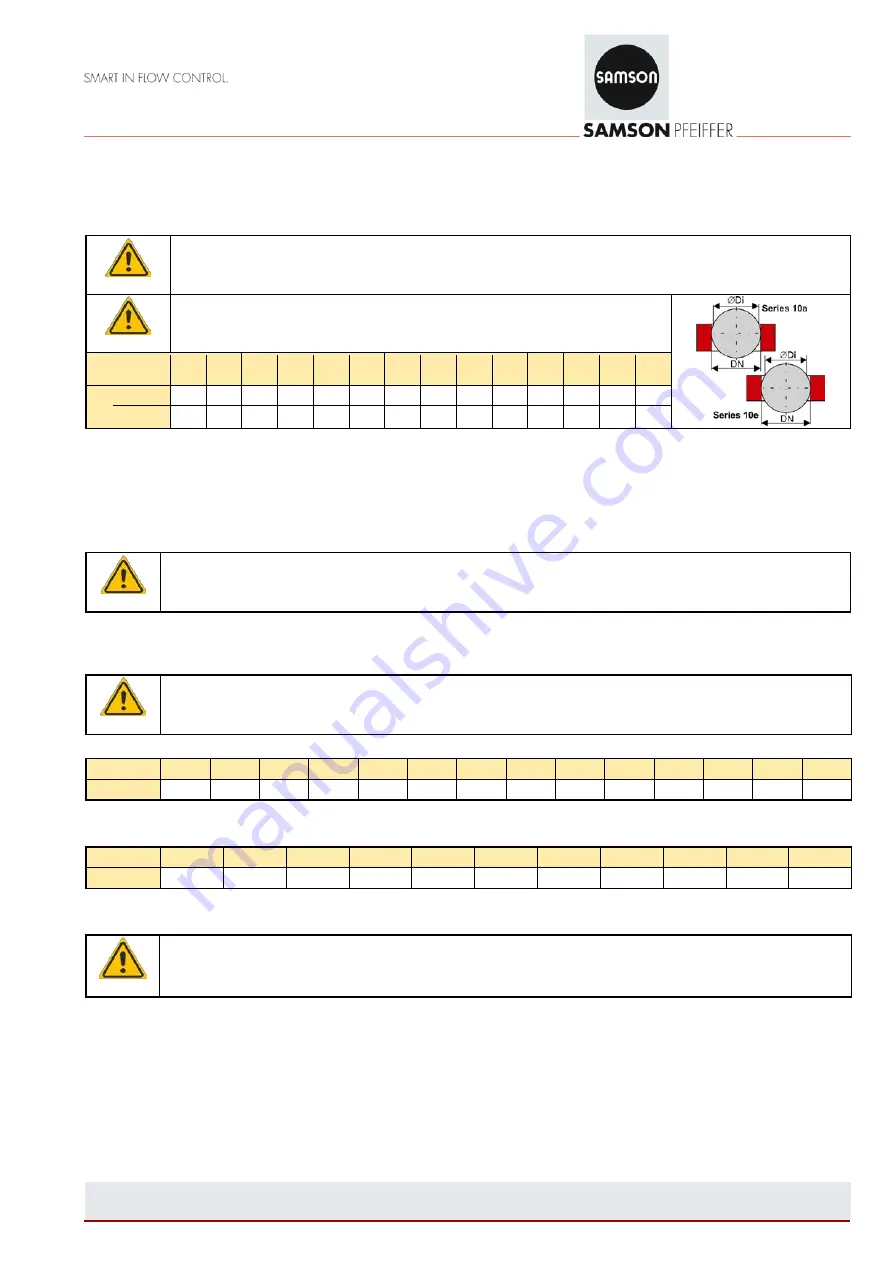

The inside diameter of the mating flanges must leave sufficient room for the

opened butterfly disc to ensure that it cannot be damaged on swinging out. See

Table 2.

DN

50

65

80

100 125 150 200 250 300 350 400 500 600 800

Di

BR10a

-

-

-

76,5

-

126 175 222 274 326 366 465 573 763

BR10e

45

45

62

86

116 140 187 238 282

-

390

-

-

-

Table 2 - Minimum required inside diameter of the mating flanges

The process medium can flow through the valve in either direction. The preferable mounting position for shut-off butterfly

valves is with a shaft in a horizontal position. However, if possible, the gear should not be located directly underneath the

shut-off butterfly valve.

Make sure the arrow on the valve body corresponds with the direction of flow in the pipeline.

Note

In special cases, it may be necessary for the valve to be tightly shut against the direction of flow. The installation

in such special cases must be determined by the operator of the pipeline (e.g. to protect a pump).

On inserting the valve (and flange gaskets) into a ready mounted pipeline, keep a certain clearance between the pipeline

ends to ensure that all facings (and gaskets) remain undamaged.

Caution

Tighten the flange bolts evenly and in a criss-cross pattern in at least three steps. Tighten all flange bolts using the

torques specified in Tables 2 or 3.

Use a torque wrench to ensure that the torque specified is reached, yet not exceeded.

DN [mm]

50

65

80

100

125

150

200

250

300

350

400

500

600

800

MA [Nm]

45

45

65

75

55

140

170

140

170

170

240

240

310

480

Table 3 – Flange torques for DIN-Flanges

DN [Zoll]

3“

4“

6“

8“

10“

12“

14“

16“

20“

24“

32“

MA [Nm]

65

50

100

150

140

160

160

230

240

300

470

Table 4 – Flange torques for ANSI-Flanges

Warning

Since PTFE plastic facings have a tendency to creep, we strongly recommend after installation to retighten the

bolted joint of the valve body using the tightening torques in Table 2 if the valves have been in storage for a long

time.

5. Pressure check in pipeline section

The pressure check of valves has already been carried out by the manufacturer. To check the pressure of a section of pipeline

with installed valves, the following points must be observed: