test parameter indicates the time that re-

mains until the next test is started.

The positioner alternately displays

“ESd”, the

Manual reference variable w,

and “MAN“.

At the end of the test, the

Status of ESD test

indicates whether the partial stroke test has

been completed successfully or not (see sec-

tion 2.2 “Analyzing measured data“).

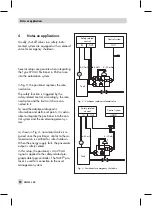

2.1.1 On-site operation

Note!

Parameters can only be changed in

positioners in ESD version after entering the

enabling ESD code (Code 3). You can only

change the reading direction (Code 2) if the

ESD code has not been entered.

The described settings can be adjusted di-

rectly on the positioner on site:

4

Entering the ESD code using Code 3

4

Selecting the ESD Man/ESD Auto oper-

ating mode using Code 0

The following modifications can only be per-

formed when the positioner is in ESD Man

operating mode:

4

Setting the reference variable

Manual w

using Code 1

4

Setting the ESD parameters using

Code 49 (see section 2.5)

Starting the partial stroke test:

1. Select operating mode ESD using

Code 0.

2. In operating mode ESD, select

ESD Man

mode, holding down the rotary

pushbutton until the countdown has

elapsed. The test will start.

Note!

Section 2.5 lists the available ESD pa-

rameters.

2.2

Analyzing measured data

TROVIS-VIEW 3:

[Diagnosis > Emergency

Shut Down > Analysis of measured data]

Analyses of the last three partial stroke tests

completed are saved in the positioner with a

time stamp.

If the test has not been completed success-

fully, the reason why the test was cancelled

is indicated under “Maintenance alarm“.

The positioner indicates “ESd tEst FAIL“. Pos-

sible reasons for cancellation depending on

the defined cancellation conditions are:

4

x cancellation: The valve position fell be-

low the

x control value.

EB 8388-1 EN

13

ESD functions

Содержание 3730-3 ESD

Страница 22: ...22 EB 8388 1 EN...

Страница 23: ...EB 8388 1 EN 23...