www.larius.com

13

GHIBLI 30:1/40:1

REV.

. 01 - 03/2020 - Cod. 150088

L

M

3 mm

M1

M2

M3

M4

M5

M6

L1

L2

M7

M7

M6

M8

M3

M3

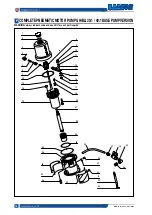

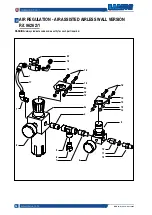

DISASSEMBLY OF THE

PNEUMATIC MOTOR

• Close the compressed air supply to the pump and release

the residual pressure in the plant.

• Unscrew the motor cap

(M1)

and pull it upwards together

with the guide rod

(M2)

.

•

Hold the guide rod

(M2)

a

nd remove the plug

(M1)

(using

two wrenches).

•

Remove the screws

(M4)

and the washers

(M5).

• Carefully extract the motor cylinder

(M6)

fom the pump.

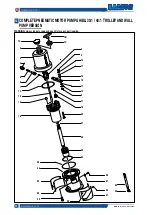

MANUAL RESET OF THE

PNEUMATIC MOTOR

• The feed air pressure of the pump must never be higher than

the maximum value indicated in the technical data. Exceed

this value can block the valves of the pneumatic motor in

the intermediate position of the cycle reversal.

• To start again a blocked motor, close the air supply and

release pressure in the plant. This operation should allow

the recovery of the valves.

• In case the motor is blocked, proceed as follows:

- Close the air supply to the pump and release the residual

pressure in the plant;

- unscrew the motor cap

(L1)

and pull it upward along with the

guide rod

(L2)

so as to manually trigger the stroke inversion

unit;

- screw again the plug.

• Check the condition of each part of the motor.

• For any eventual replacement of the screws

(M7)

of the

traverse

(M8)

, for their reassembly and correct adjustment.

Replace immediately the plug

(M1)

with a usual

M8

(M3)

nut before the guide rod slides into the

cylinder.

Fig. 1M

Fig. 1L

Fig. 2M