18

Manual Chuck

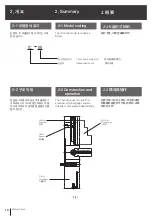

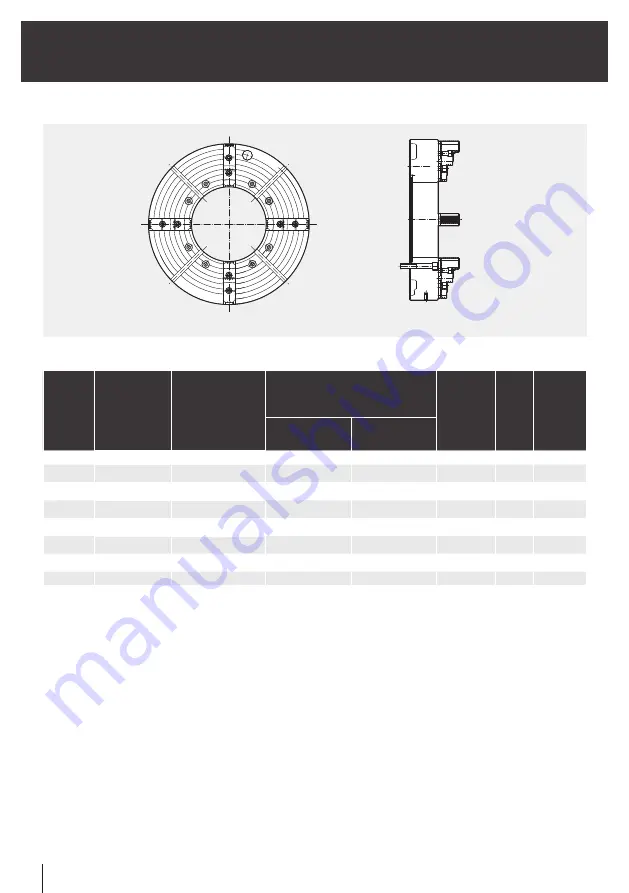

※ IC-3232

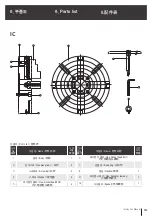

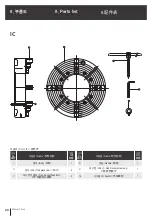

IC

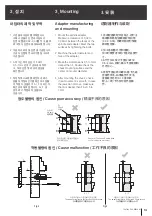

7. Specification

7. 技术参数

7. 사 양

사양 / Specification /

规格

형식

Type

型式

핸들입력토크

Handle input

torque

최대정적 파악력

Max. Static Grip Force

最大静态夹持力

[kN (kgf)]

파악경

Grip dia.

夹持直径

허용최고

회전속도

Max. R.P.M.

最大转速

[min

-1

(r.p.m.)]

중량

Weight

重量

[kgf]

관성모멘트

GD²

转动惯量

[N·m²

(kgf·m²)]

외측 / External / 外

Ø

mm

내측 / Internal /

内

Ø

mm

IC-2018

294Nm(30Kgf-m)

27.4 (2800)

460

450

800

180

54.9 (5.6)

IC-2023

294Nm(30Kgf-m)

27.4 (2800)

460

450

800

170

51.41 (5.3)

IC-2423

345Nm(35.2Kgf-m)

28.5 (2904)

550

550

800

350

61.74 (6.3)

IC-2427

390Nm

30 (3056)

550

550

800

340

61.74 (6.3)

IC-2432

390Nm

30 (3056)

550

550

800

330

61.74 (6.3)

IC-3232

392Nm(40Kgf-m)

32.4 (3300)

750

730

600

500

382 (39)

IC-3237

392Nm(40Kgf-m)

32.4 (3300)

750

730

600

490

382 (39)

IC-4056

392Nm(40Kgf-m)

36 (3700)

1000

900

480

660

-

If the using of chuck is too heavy or

too long, Please support with Steady

rest or tailstock. Otherwise, the body

and jaws get damaged

단동척 사용이 소재가 과도한 중량 혹은

길이가 긴 경우 방진구 혹은 심압대로 지

지해 주십시오. 그렇지 않으면 바디 및

죠가 파손될 수 있습니다.

如果重量过大或过长,请用防振装置

或尾架支撑单动卡盘。

否则,身体和下巴可能会断裂。

Содержание IC

Страница 2: ......

Страница 4: ...4 Manual Chuck 1 7 2 12 2 1 12 2 2 12 3 13 4 14 5 15 6 16 7 17 8 18...

Страница 6: ...6 Manual Chuck 1 7 2 12 2 1 12 2 2 12 3 13 4 14 5 15 6 16 7 17 8 18...

Страница 21: ...5 1 2 1544 3122 IC 12 405 820 99 A S TEL 032 822 4811 FAX 032 822 4377...

Страница 23: ...5 1 2 IC 12 405 820 99 Namdong daero Namdong gu Incheon Korea TEL 82 32 899 8965 FAX 82 32 721 7607...