5

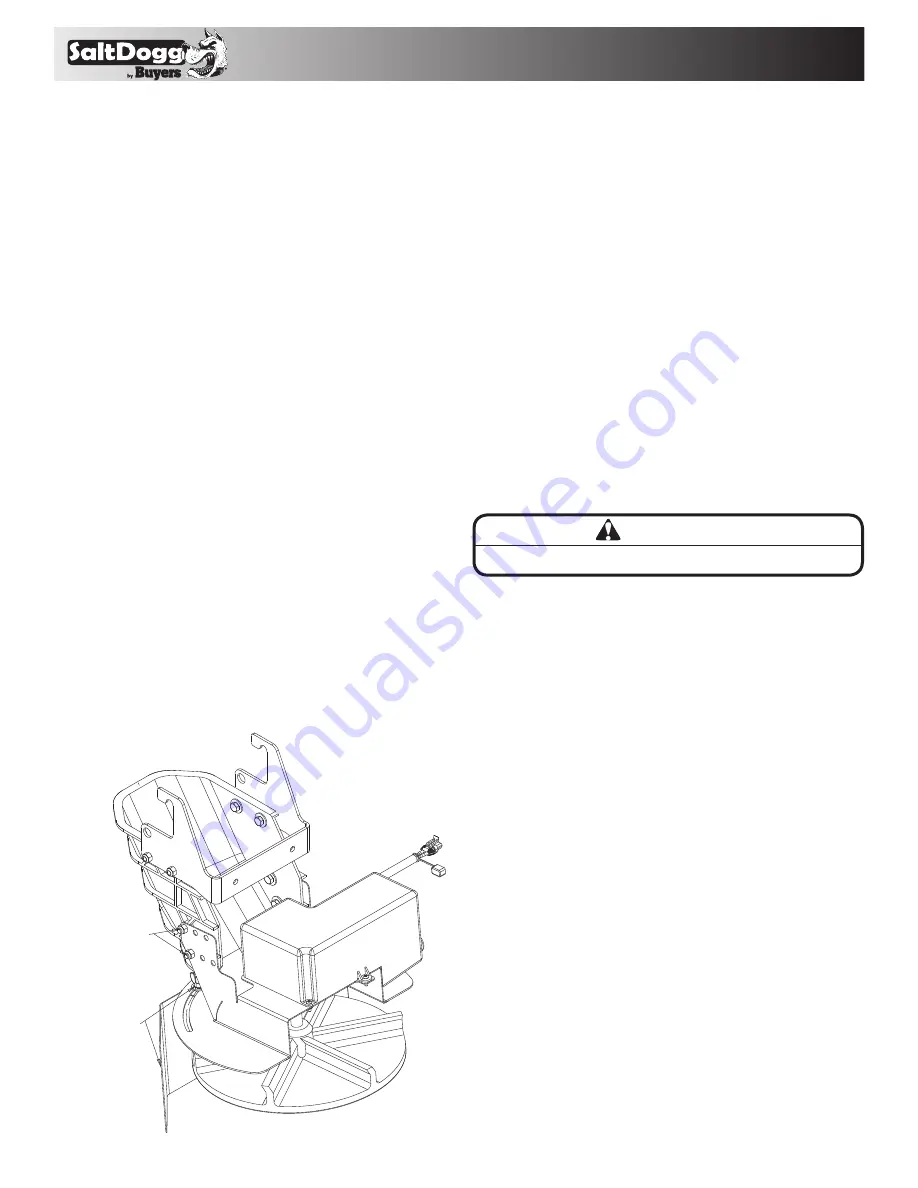

Fig. 8

Material Flow Adjustments

Always use screen during spreader operation!

Various materials have different moisture absorption rate,

some materials may not perform as desired. Therefore, the

substitution of the alternate material may be necessary for

optimum performance.

SHPE2000 has two discharge openings in the bottom of the

hopper. Material flow through these openings can be controlled

using two sliding baffles. The spreader is shipped from the

factory with baffles adjusted for dry bagged salt. In this setting

rear baffle has 4.0" opening and baffle in the middle of the

hopper has 2.0" opening. However if you are using a sand/

salt mixture or any chunky and hard to flow materials. Adjust

the rear baffle opening to 3" and the baffle in the middle of the

hopper to a 1" opening.

IMPORTANT! -Always open rear (closer to gear motor

compartment) opening first. Always turn off power before

adjusting baffles!

Spread Pattern Adjustment.

Spread pattern can be adjusted by changing spinner disc speed

on controller by turning Spinner knob to desired speed level

from 1 (low) to 9 (high). Direction of material spread can also be

adjusted by rotating shield on chute assembly. To rotate shield

lose 2 wing nuts, rotate shield in desired direction, and retighten

wing nuts. See Fig.8. Make sure that after adjustment, bracket

stays inside shield groove located on top of shield. In addition,

chute assembly can be adjusted to lighter (drier) and heavier

(more moist) materials. Use different holes on bracket for lighter

or heavier materials to have material drop on spinner disc

center. See Fig.8.

Spreader Maintenance

1.

Wash spreader after every use. Make sure no material is left

under auger and/or inside trough.

2.

Inspect and retighten fasteners after every 5-7 hours of

operation.

3.

Lubricate bearing every 7-10 hours of operation using

general automotive grease.

4.

Inspect terminals/connectors every time you disconnect

spreader from wire harness. Apply thin layer of dielectric grease

on terminals. If any tarnish/corrosion is found, clean terminals

and apply dielectric grease.

5.

Use dielectric grease on all electrical connectors before an

electrical connection is made or after connector is disconnected

6.

Grease and spray with lubricant Auger bearing after every 20

hours of use.

7.

Empty the spreader of all ice control materials when not in

use. Wash out the spreader to prevent material builds up.

8.

It is recommended to cover spreader with the tarp during

storage periods.

LOOSE WING NUTS

ROTATE SHIELD

HOLES FOR BRACKET

POSITION ADJUSTMENT

WARNING

Never remove spreader with material in hopper.

End of Season Maintenance

1.

Wash spreader. Make sure no material or residue is left in and

outside the hopper.

2.

Lubricate bearing using general automotive grease.

3.

Inspect wire harness, connectors for broken insulation, missing

components. Replace if necessary.

4.

Apply dielectric grease on all electrical connectors.

5.

Store hopper indoors, in a dry, cool place.

6.

Remove controller from truck. Store controller indoors, in a dry,

cool place.

7.

Inspect wire near connectors. Check for broken or missing

insulation. Check for tarnished or corroded wires. Trim corroded

wires and replace connectors if necessary.

Summer Storage

1.

Apply dielectric grease or similar protective compound on all

electrical connectors & protect them with caps before storage.

2.

Disconnect and remove speed controller from vehicle and

store it in dry and cool place. Protect controller from excessive

heat and moisture.

3.

Clean hopper and trough from all kinds of debris.

4.

Remove, thoroughly lubricate and reinstall trough bearing.

5.

Protect hopper from excessive temperatures during

summer storage.