Powered by Safety

®

28

Installation

01.4IB.77020

PowlVac-ND

®

and PowlVac-NDA

™

Series 4

Vacuum Circuit Breakers

The tests described above are the only tests

required to ascertain insulation integrity.

Because of the design of the PowlVac

®

insulation system, no valid data can be

obtained utilizing other types of high voltage

insulation tests.

2) Vacuum Integrity

Applying abnormally high voltage across

a pair of contacts in vacuum may produce

x-radiation. The radiation may increase with

increased voltage and/or decreased contact

spacing.

X-radiation produced during this test with

the voltage specified in

and normal

contact spacing is extremely low and well

below the maximum permitted by standards.

Do NOT apply voltage that is higher than the

recommended value. Do NOT use contact

separation that is less than the normal open

position separation of the circuit breaker

contacts.

!

CAUTION

Powell recommends AC testing for reliable

verification of vacuum integrity. All

PowlVac-ND® and PowlVac-NDA™ Series

4 circuit breakers shall be tested with

a minimum of 25kVAC applied across

fully open contacts for 10 seconds. No

dielectric breakdown during the test period

constitutes a successful test.

Note:

This test does not replace the AC

high potential testing (Hipot) used to

determine “High voltage insulation

integrity.” See

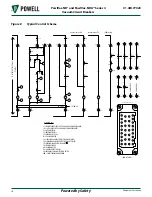

D. Placing the Circuit Breaker Into

Service, 1) High Voltage Insulation

.

Powell offers a compact and lightweight

PowlVac

®

Vacuum Integrity Tester

designed specifically for PowlVac

®

circuit

breakers. If this device is used refer to

the instruction bulletin provided with the

vacuum integrity tester.

Powell recognizes the widespread use

of DC hipot equipment in the field and

the desire to use this equipment to verify

vacuum integrity. However, the capacitive

component of the vacuum interrupter

during DC testing may yield false negative

test results, which are often misinterpreted

as vacuum interrupter failure. When DC

testing is performed, a test set providing a

full wave rectified 35kV DC hipot voltage

can be applied for 5 seconds as a

“go - no go” test.

Recording the leakage readings is not

necessary, as a dielectric breakdown will

trip all portable DC hipot test sets. If a

DC test breakdown occurs, the test must

be repeated after reversing the DC high

voltage test supply connection across the

vacuum interrupter. A vacuum interrupter

should be questioned only if it has failed

both tests.

High voltages across the open gaps of the

vacuum interrupter can produce

x-radiation. When conducting high voltage

test, personnel should stand at least one

meter (3’) away from the circuit breaker with

the covers in place. Vacuum Integrity Test

voltages should not exceed 25kVAC (35kVDC)

for circuit breaker with a rated maximum

voltage of 4.76kV.

!

CAUTION