9

XL-SA20018UM-en-US Rev H · 2017-12-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Disc Brake Inspection

6. Disc Brake Inspection

IMPORTANT:

During removal inspect components for

wear and replace worn components.

Failure to properly support axle during

maintenance could allow axle to fall

which, if not avoided, could result in

death or serious injury.

NOTE:

For further disc brake inspection information, refer

to the latest version of the TMC recommended

practice RP 652–Service and Inspection of Air Disc

Brakes (TMC DVD supplement).

6.1 Pad Wear Inspection

Check the brake pads for proper thickness at regular service

intervals based on vehicle usage. Brake pad inspections should

be carried out at least every three (3) months or 20,000 miles,

whichever comes first, and in accordance with any legal

requirements. Refer to Routine Service Schedule in Section 19.

NOTE:

Regular service intervals may be required more

frequently for severe duty applications. Refer to

Section 19.

A quick visual inspection of the condition of the brake pads

can be performed without removing the wheel:

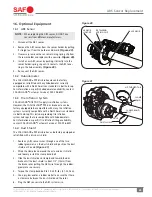

1. Compare the position of the caliper marking to the

carrier marking located on the underside of the caliper

unit

(Figure 7)

.

a.

Figure 7

- View A shows the positions of the two (2)

markings when the brake pads are in good condition.

b.

Figure 7

- View B shows the positions of the two (2)

markings when the wheel MUST be removed for further

inspection of wear to the brake pads and brake rotor.

For further inspection of the brake pads, the wheel and brake

pads MUST be removed. Refer to Section 5 for caliper and service

manual identification.

IMPORTANT:

After inspecting the brake pads, check that

the brake system is functioning properly.

IMPORTANT:

When replacing worn brake pads, ALL pads

on the axle MUST be replaced.

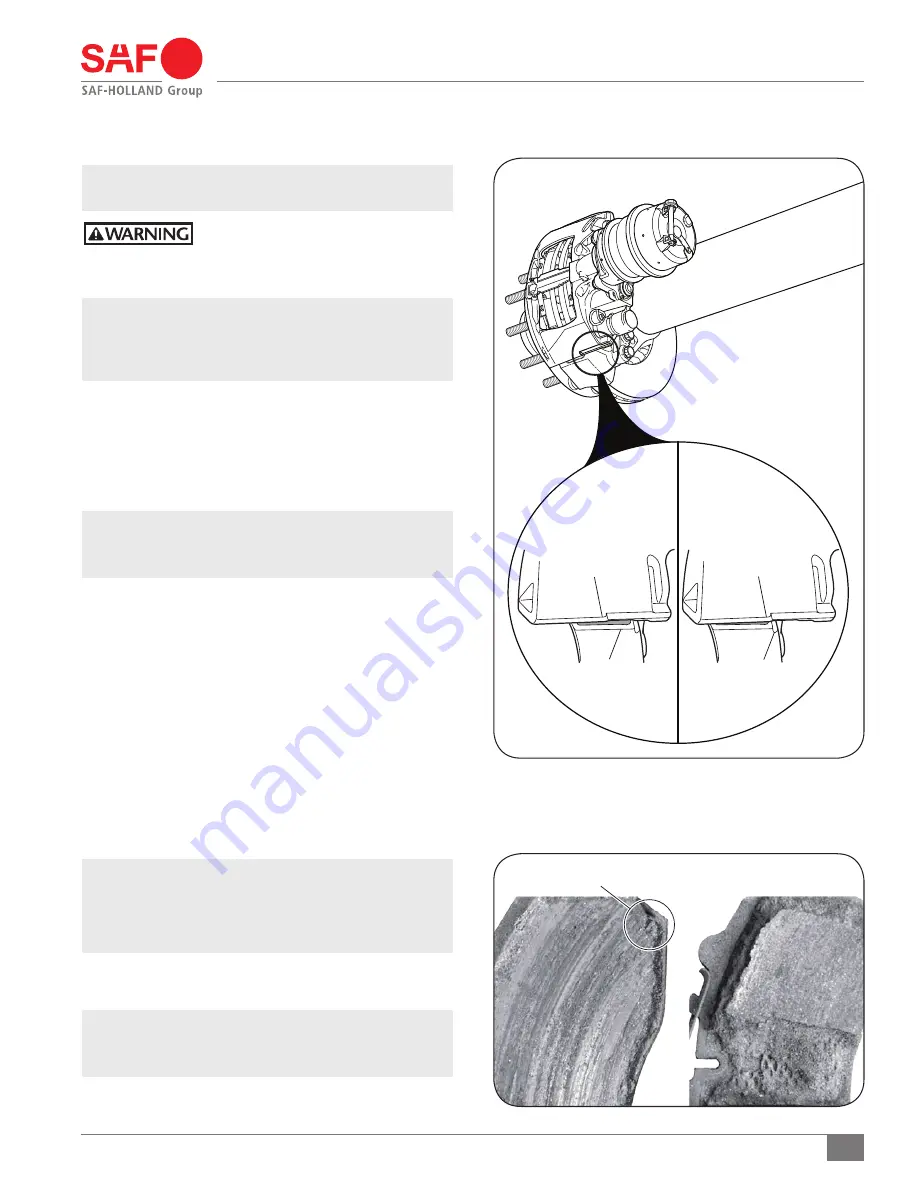

If the friction material of the brake pad is less than 0.43" (2 mm) at

its thinnest area, the brake pad MUST be replaced.

(Figure 10)

.

NOTE:

Minor breakouts at the edges are permitted. Major

breakouts on the surface of the brake pad are NOT

permitted

(Figure 8)

.

Figure 8

Figure 7

CARRIER

MARKING

CARRIER

MARKING

PERMITTED

NOT PERMITTED

VIEW A

VIEW B

CALIPER

MARKING

CALIPER

MARKING