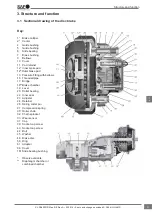

5. Function and visual inspection

5.1 Wear inspection of brake pads and

brake discs

For optimum safety, always remain within the

wear limits of brake pads and brake discs.

Danger !

Brake pads

Check the thickness of brake pads at regular

intervals according to use of the vehicle and in

accordance with the statutory provisions, however

every three months as a minimum, even if a brake

pad wear indicator is connected.

5.1.1 Small cavities on the edges are permissible

(see Fig.).

5.1.2 Large cavities on the surface of the brake

pad are impermissible (see Fig.).

5.1.3 In the event that the thickness of the friction

material at its thinnest point is less than/equal to

2 mm (dimension C), the pads must be replaced

(see Fig.).

A = Overall thickness of a new brake pad 32 mm

B = Pad carrier plate 9 mm

C = Minimum thickness of friction material 2 mm*

D = Absolute minimum thickness of brake pad

11 mm*

*In the event that these minimum thicknesses are

reached, the brake pads must be replaced.

Brake discs

Measure the thickness of the brake disc at the

weakest point (note any burrs on the edge of the

brake disc).

Observe the information from the vehicle/axle

manufacturer.

E = Overall thickness of the brake disc

New dimension = 45 mm

Minimum dimension = 37 mm (brake disc must be

replaced)

In the event that dimension E ≤ 39 mm, the brake

disc must

also be replaced when replacing the pad.

5.1.1 - Brake pad with permissibly small cavities

5.1.2 - Brake pad with impermissible cavities

5.1.3 - Dimensions of brake pad and brake discs

Function and visual inspection

13

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND