16

XL-AS20012BM-en-US Rev B · 2014-05-28 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND,

SAF, and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Operation Instructions

FLIPPER PLATE IN THE

ENGAGED POSITION

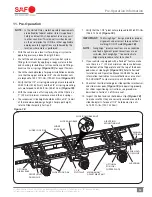

13. PosiLok

™

Anti-Dock Walk (Optional

Equipment)

The CBX69 suspension can be equipped with SAF

®

PosiLok

™

which provides enhanced trailer stability during loading and

unloading operations. If the trailer air control system employs

a “spring brake priority” type arrangement, potential field

service issues may arise due to operational misuse, such as:

Moving a trailer before the air springs have been

properly inflated.

Use of yard hustler equipment.

Heavy load operations, such as paperhaul, with the slider

in the full forward position.

Engaging the emergency trailer brakes at a high rate of

speed (greater than 5 mph) to move the slider position.

Use of an auxiliary suspension dump valve with excessive flow.

Going in and out of ramped docks with slider all the

way forward.

SAF

®

PosiLok

™

system will properly support the trailer during

normal operations and is designed to bend or buckle when

subjected to overloading or other operational issues to

protect the trailer sub-frame.

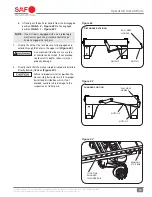

The PosiLok

™

is engaged when the flipper

plates are in the down position.

1. Release air pressure from the trailer brake system or

disconnect the glad hand. This engages the parking

brakes and causes the PosiLok

™

actuator to engage,

which rotates the rod so the flipper plates swing down

into an engaged position

(Figure 25)

.

The PosiLok

™

is disengaged when the flipper

plates are in the up position.

1. When the parking brakes are disengaged, the primary height

control valve (HCV) takes full function. When the system

has sufficient air pressure in the suspension air springs,

the actuator extends, rotating the rod so the flipper plates

swing up away from the load pads into a disengaged

position

(Figure 26)

. The vehicle is now ready for movement.

IMPORTANT:

DO NOT operate vehicle (put in motion) if

flipper plates are trapped in the down position

(Figure 27)

. Refer to the troubleshooting

section of Installation and Operation

Manual XL-AS20001BM-en-US. Available at

www.safholland.us or contact SAF-HOLLAND

®

Customer Service at 888-396-6501.

Failure to adequately raise flipper

plates could result in trailer, suspension

component, and cargo damage.

Figure 26

Figure 27

Figure 25

FLIPPER PLATE IN THE

DISENGAGED POSITION

FLIPPER PLATE

TRAPPED IN THE

DOWN POSITION